Technology for preparing micro-molecular phenolic compound through microwave reinforced continuous degradation of lignin in hydrogen donor

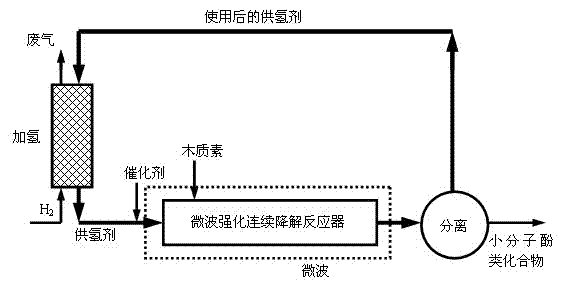

A technology of phenolic compounds and lignin, which is applied in the field of microwave-enhanced continuous degradation of lignin in a hydrogen donor to prepare small molecule phenolic compounds, can solve the problems of high reaction temperature, long reaction time, and large energy consumption, and achieve the goal of reaction Speed increase, to solve the effect of discontinuous response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

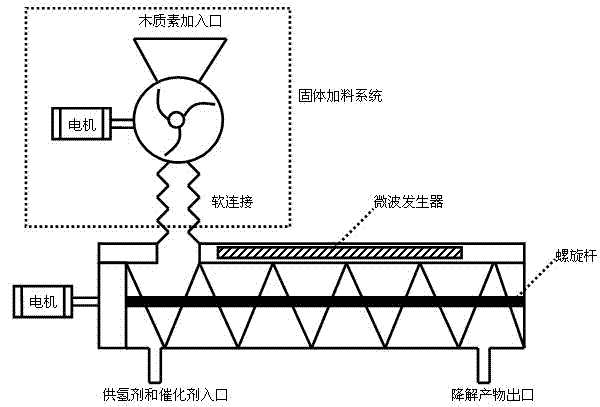

Method used

Image

Examples

Embodiment 1

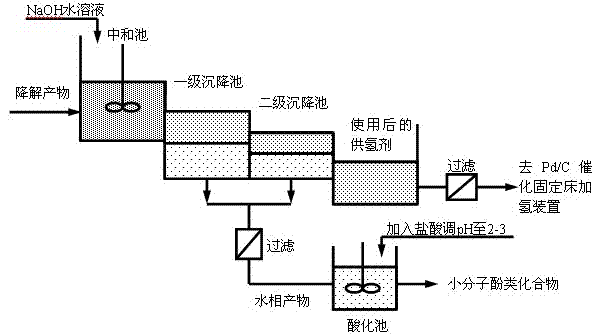

[0031] Lignin is continuously added to the microwave-enhanced continuous degradation reactor by a pump through a solid feeding system, tetralin and p-toluenesulfonic acid, wherein the mass ratio of lignin, tetralin and p-toluenesulfonic acid is 30:60:1, Continuous degradation reaction at 180°C for 20 minutes; the degradation product is neutralized with NaOH aqueous solution in the neutralization tank of the degradation product separation device, and enters the primary settling tank and the secondary settling tank successively, and the primary settling tank and the lower layer of the secondary settling tank The products were combined, and the aqueous phase product was obtained by filtration, and then the pH was adjusted to 2~3 with hydrochloric acid in the acidification tank to obtain a small molecular phenolic compound. The product was analyzed by GC-FID, and the yield of the small molecular phenolic compound was calculated as 15.8%. The upper layer of the secondary settling t...

Embodiment 2

[0033] Lignin is continuously fed into the microwave-enhanced continuous degradation reactor through a solid feeding system, decahydronaphthalene and hydrochloric acid through a pump, wherein the mass ratio of lignin, decahydronaphthalene and hydrochloric acid is 30:30:1, and is continuously degraded at 150°C React for 40 min; the degradation product is neutralized with NaOH aqueous solution in the neutralization tank of the degradation product separation device, and enters the primary sedimentation tank and the secondary sedimentation tank successively, and the lower layer products of the primary sedimentation tank and the secondary sedimentation tank are combined and filtered to obtain The water phase product was then adjusted to pH 2~3 with hydrochloric acid in the acidification tank to obtain small molecular phenolic compounds. The product was analyzed by GC-FID, and the yield of small molecular phenolic compounds was calculated to be 2.9%. The upper layer of the secondary ...

Embodiment 3

[0035] Lignin is continuously fed into the microwave-enhanced continuous degradation reactor through a solid feeding system, dihydroanthracene and sulfuric acid through a pump, wherein the mass ratio of lignin, dihydroanthracene and sulfuric acid is 50:150:1, and it is continuously degraded at 160°C Reacted for 35 min; the degradation product was neutralized with NaOH aqueous solution in the neutralization tank of the degradation product separation device, and entered into the primary sedimentation tank and the secondary sedimentation tank successively, and the lower layer products of the primary sedimentation tank and the secondary sedimentation tank were combined, and obtained The water phase product was then adjusted to pH 2~3 with hydrochloric acid in the acidification tank to obtain small molecular phenolic compounds. The product was analyzed by GC-FID, and the yield of small molecular phenolic compounds was calculated to be 13.5%. The upper layer of the secondary settling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com