Electrochromic fiber and preparing method and application thereof

An electrochromic and electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inapplicable methods, complex structures, and inability to continuously prepare, and achieve simple preparation methods, simplified device structures, and low discoloration voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Using 1,1'-diethyl-4,4'-bipyridyl dibromide (EtVio) as a color-changing material, dissolve EtVio and ferrocene (both at a concentration of 20 mmol / L) at a molar ratio of 1:1 In PC, add BMIBF 4 and PVDF, stir evenly, PC, BMIBF 4 The mass ratio to PVDF is 1:0.34:0.55, and the electrochromic electrolyte active layer solution is prepared.

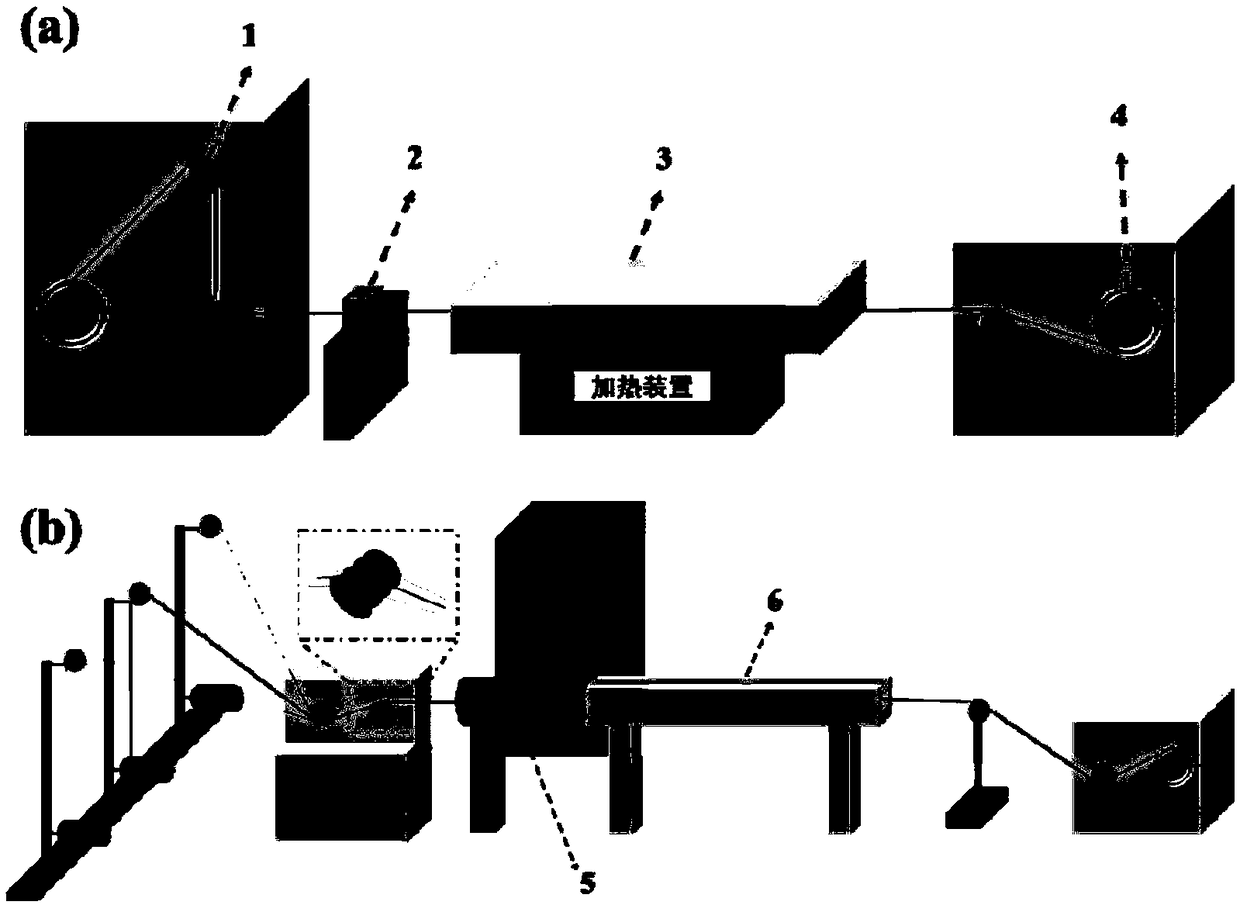

[0039] Self-built fiber continuous preparation device (see figure 1 ), the above solution is coated on the surface of the metal fiber through the solution tank, collected after high temperature curing, and the above steps are repeated until the thickness of the electrolyte active layer reaches about 60 μm. The hole diameter of the solution tank is 0.65mm, the fiber transmission speed is 3m / min, and the curing temperature is 130°C.

[0040] Prepare a polyethylene protective layer on the outer layer of the above fiber by extrusion, and wrap two metal wire outer electrodes in parallel on both sides of the above fiber, control the thickn...

Embodiment 2

[0047] Using EtVio as the color-changing material, dissolve EtVio and ferrocene (concentration: 5mmol / L) in PC at a molar ratio of 1:1, add BMIBF 4 and PVDF, stir evenly, PC, BMIBF 4 The mass ratio to PVDF is 1:0.34:0.55, and the electrochromic electrolyte active layer solution is prepared.

[0048] Self-built fiber continuous preparation device (see figure 1 ), the above solution is coated on the surface of the metal fiber through the solution tank, collected after high temperature curing, and the above steps are repeated until the thickness of the electrolyte active layer reaches about 15 μm. The hole diameter of the solution tank is 0.4mm, the fiber transmission speed is 3m / min, and the curing temperature is 130°C.

[0049] Prepare the polyethylene protective layer on the outer layer of the above fiber by extrusion, and wrap two metal wire outer electrodes in parallel on both sides of the above fiber, control the thickness of the protective layer to 1mm, and finally coll...

Embodiment 3

[0052] Using EtVio as the color-changing material, dissolve EtVio and ferrocene (concentration: 20mmol / L) in PC at a molar ratio of 1:1, add BMIBF 4 and PVDF, stir evenly, PC, BMIBF 4 The mass ratio of PVDF and PVDF is 1:0.34:0.55 to prepare the electrochromic electrolyte active layer solution.

[0053] Self-built fiber continuous preparation device (see figure 1 ), the above solution is coated on the surface of the metal fiber through the solution tank, collected after high temperature curing, and the above steps are repeated until the thickness of the electrolyte active layer reaches about 100 μm. The hole diameter of the solution tank is 1mm, the fiber transmission speed is 3m / min, and the curing temperature is 130°C.

[0054] Prepare a polyethylene protective layer on the outer layer of the above fiber by extrusion, and wrap two metal wire outer electrodes in parallel on both sides of the above fiber, control the thickness of the protective layer to 0.5mm, and finally c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com