Fluidized bed chemical vapor deposition preparation method of silicon carbide nanoparticle

A chemical vapor deposition, nanoparticle technology, applied in nanotechnology and other directions, can solve the problems of containing other elements, impurities, narrow particle size distribution, etc., to achieve the effect of rich application scope, convenient process operation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The precursor, hexamethyldisilane, was heated to 80° C. by means of a water bath, and argon was used as the carrier gas, the flow rate of the carrier gas was 0.3 L / min, and the mixed gas of hydrogen and argon was used as the fluidizing gas, and H 2 The flow rate of Ar is 1.2L / min, and the flow rate of Ar is 1.5L / min. The fluidized bed reactor was heated to 900°C, zirconia fluidized particles were added and the carrier gas was introduced, and the powder was collected by the powder collection system at the top of the reactor. The obtained powder was heat-treated in an argon atmosphere at 1300°C for 1 hour.

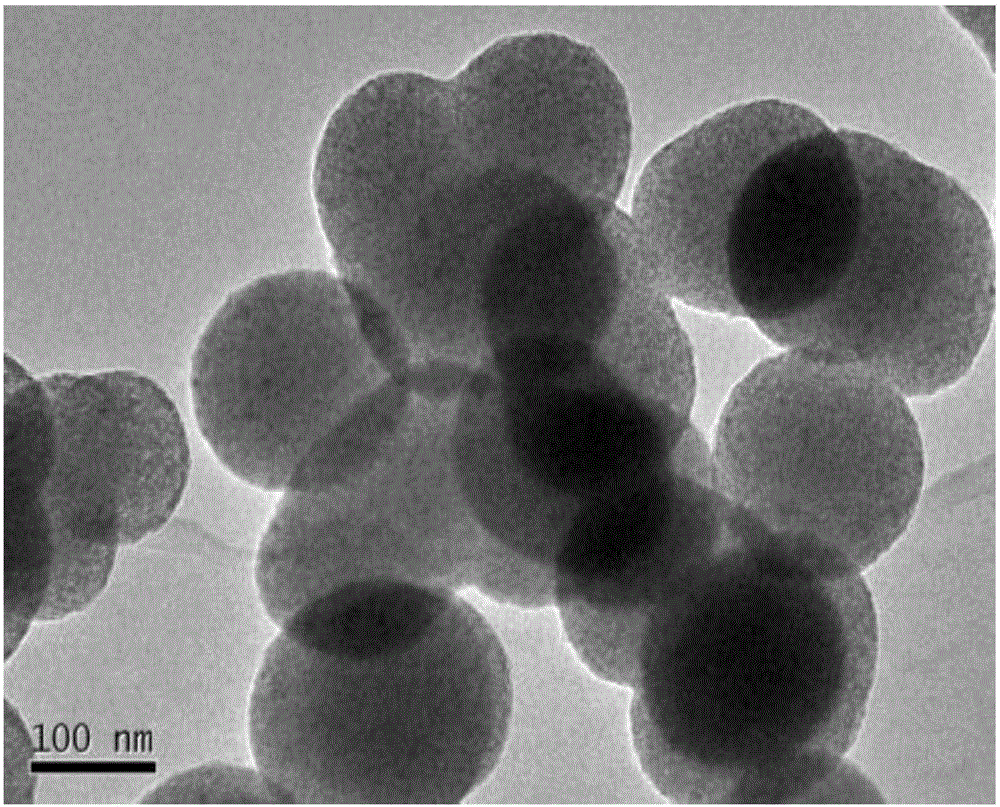

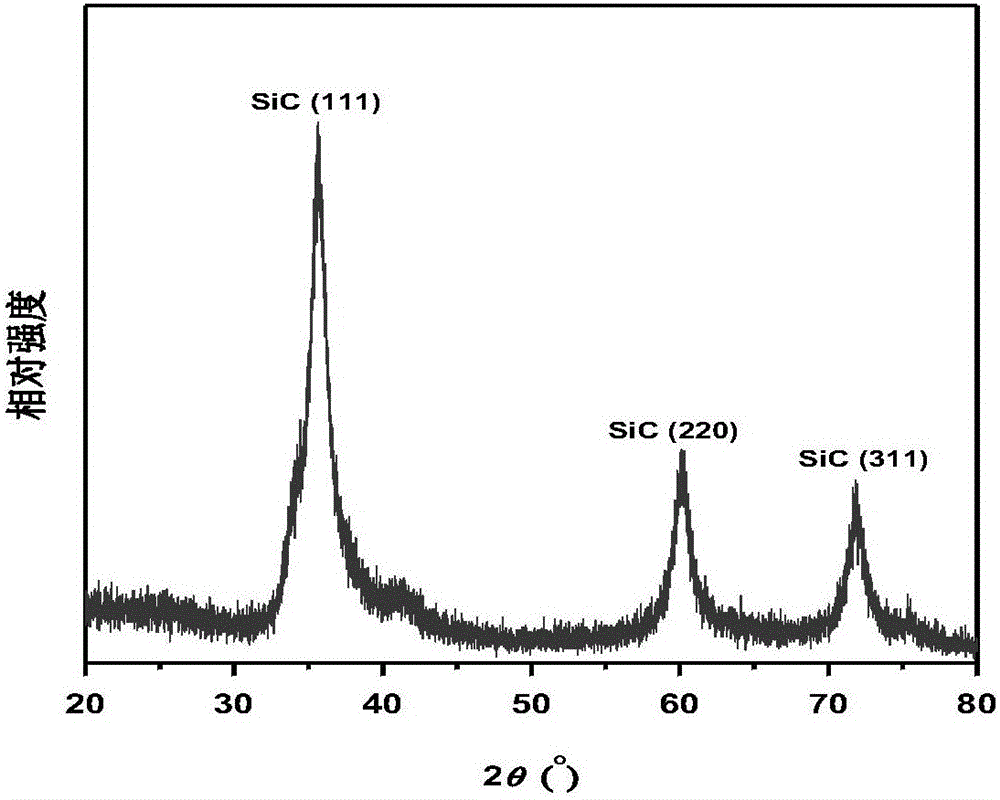

[0034] The transmission electron microscope photo of the obtained product is as figure 1 It can be seen that the obtained product is monodisperse spherical particles, the particle size distribution is very narrow, the average particle size of the product is 120 nm, and the XRD spectrum of the product is as follows figure 2 As shown, by comparing the standard card, ...

Embodiment 2

[0036] The precursor, hexamethyldisilane, was heated to 80°C by means of a water bath, and argon was used as the carrier gas. 2 The flow rate of Ar is 1.5L / min, and the flow rate of Ar is 0.9L / min. The fluidized bed reactor was heated to 900°C, zirconia fluidized particles were added and the carrier gas was introduced, and the powder was collected by the powder collection system at the top of the reactor. The obtained powder was heat-treated in an argon atmosphere at 1300°C for 1 hour.

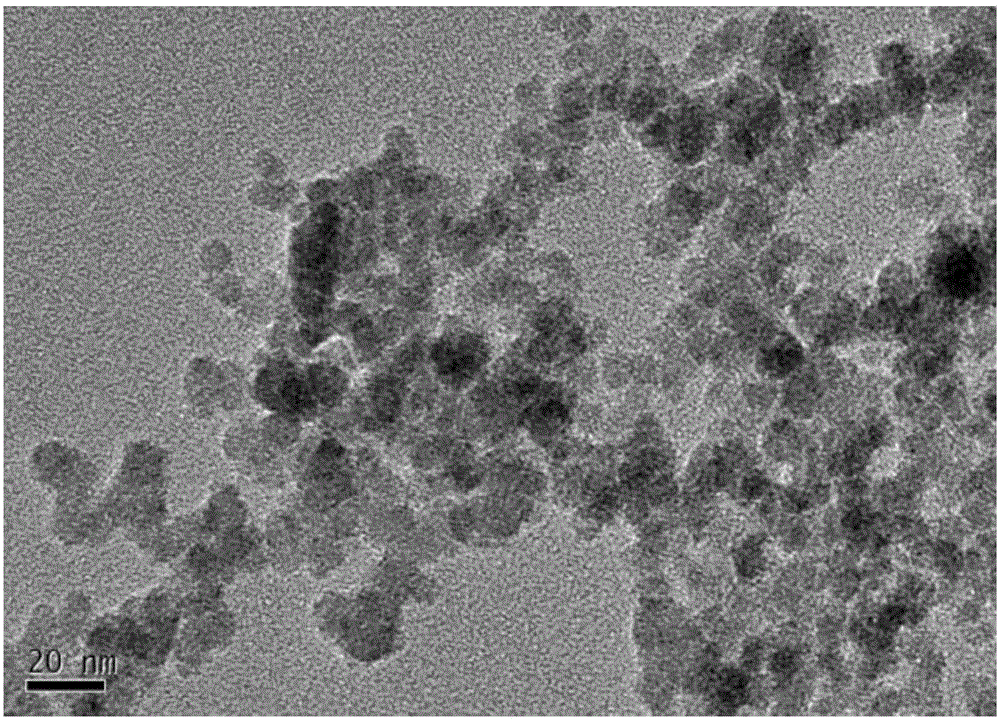

[0037] The transmission electron microscope photo of the obtained product is as image 3 As shown, it can be seen that the obtained product is monodisperse spherical particles, and the average particle size of the product is 15 nanometers. The XRD test of the product shows that the standard card product is cubic phase silicon carbide, and there is no other impurity phase.

Embodiment 3

[0039] The precursor, hexamethyldisilane, was heated to 100°C by means of electric heating, using hydrogen as the carrier gas, the flow rate of the carrier gas was 2.0L / min, and the mixed gas of hydrogen and argon was used as the fluidizing gas, H 2 The flow rate of Ar is 1.0L / min, and the flow rate of Ar is 1.5L / min. The fluidized bed reactor was heated to 800°C, the metal cobalt fluidized particles were added and the carrier gas was introduced, and the powder was collected by the powder collection system at the top of the reactor. The obtained powder was heat-treated in an argon atmosphere at 1400°C for 2 hours.

[0040] The obtained product is a monodisperse spherical particle with a narrow particle size distribution. The average particle size of the product is 280 nanometers. The product is tested by XRD. By comparing with the standard card product, the product is cubic phase silicon carbide, and there is no other impurity phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com