Method for preparing graphene by using supercritical fluid

A technology of supercritical flow and graphene, which is applied in the production of bulk chemicals, etc., can solve the problems of difficulty in preparing high-quality graphene, difficulty in large-scale production, harsh preparation conditions, etc., and achieve easy operation, continuous preparation, easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

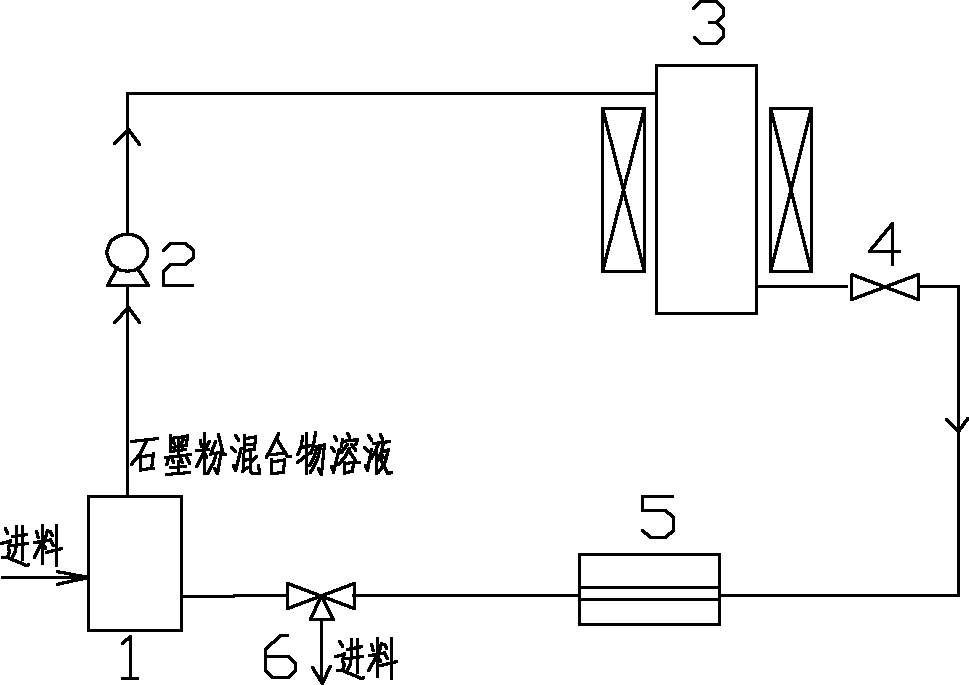

[0018] like figure 1 As shown, the preparation device involved in this embodiment mainly includes: an ultrasonic vessel 1, a pump 2, an autoclave 3, a valve 4, a cooling pool 5, and the like. The ultrasonic container 1, the pump 2, the autoclave 3, the valve 4, the cooling pool 5, etc. are sequentially connected through pipelines to form a circulation loop, and a discharge port 6 is provided between the ultrasonic container 1 and the cooling pool 5.

[0019] Ethanol was selected as the organic solvent, a certain amount of graphite powder and a certain amount of ethanol were added to the ultrasonic container 1, and the graphite powder was uniformly mixed in the organic solvent by ultrasonication, and the ultrasonication time was 10 minutes. The above-mentioned graphite powder mixed solution in the ultrasonic container 1 is pumped into the autoclave 3, the inlet of the pump 2 is connected with the outlet of the ultrasonic container 1 through a pipeline, and the outlet of the pum...

Embodiment 2

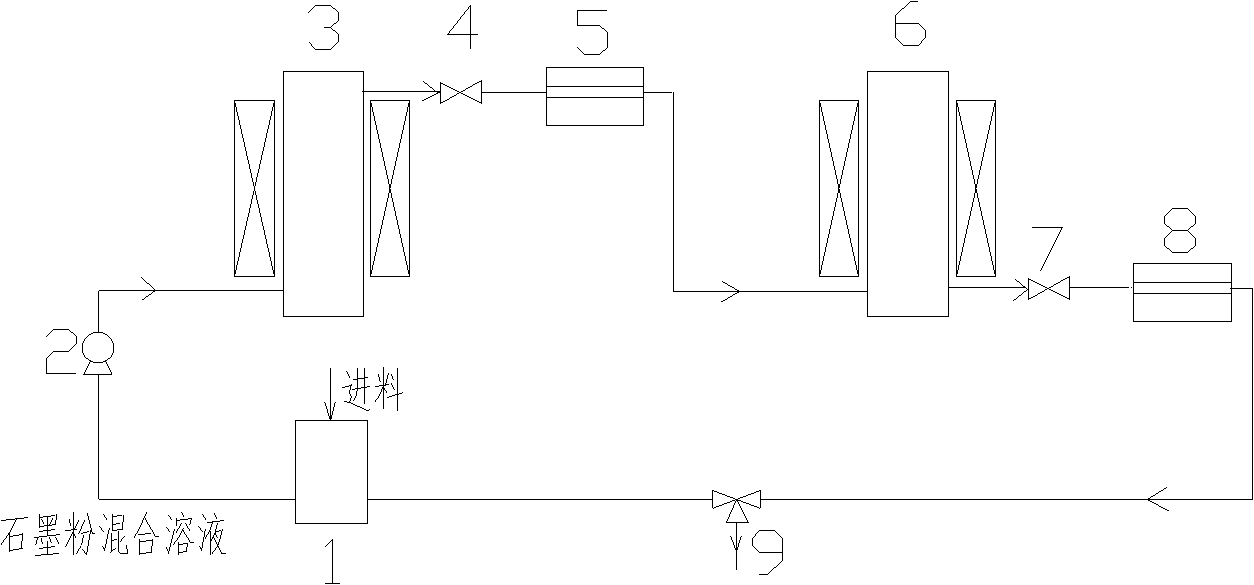

[0022] like figure 2 As shown, the preparation device involved in this embodiment mainly includes: an ultrasonic container 1, a pump 2, an autoclave 3, a valve 4, a cooling pool 5, an autoclave 6, a valve 7, a cooling pool 8, and the like. The ultrasonic container 1, pump 2, autoclave 3, valve 4, cooling pool 5, autoclave 6, valve 7, cooling pool 8, etc. are connected in sequence through the pipeline to form a circulation loop, and the ultrasonic container 1 and the cooling pool 8 are set up Outlet 9.

[0023] Choose dimethylformamide as the organic solvent, add a certain amount of graphite powder and a certain amount of dimethylformamide into the ultrasonic container 1, and make the graphite powder evenly mixed in the organic solvent by ultrasonic, and the ultrasonic time is 15 minutes. The above-mentioned graphite powder mixed solution in the ultrasonic container 1 is pumped into the autoclave 3, the inlet of the pump 2 is connected with the outlet of the ultrasonic contai...

Embodiment 3

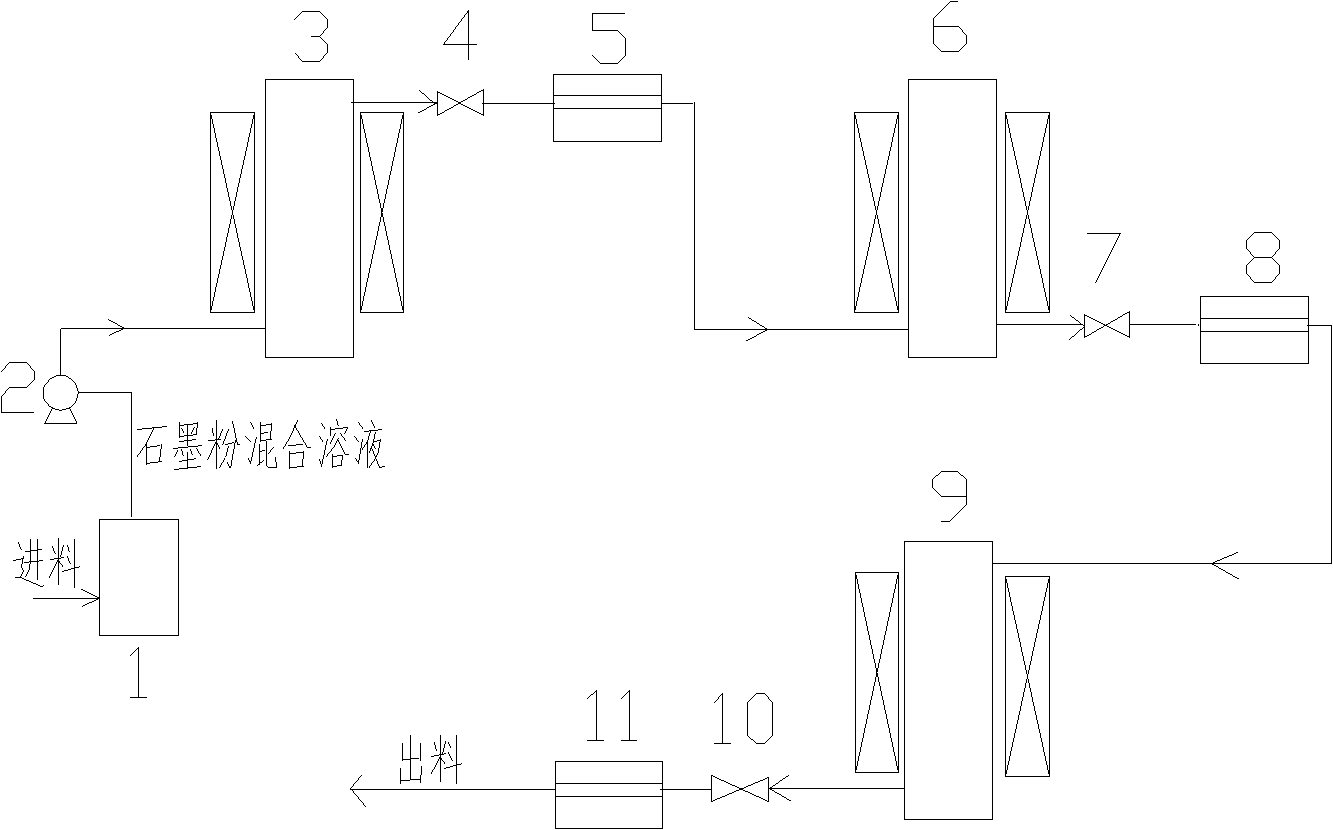

[0026] like image 3 As shown, the preparation device involved in this embodiment mainly includes: ultrasonic container 1, pump 2, autoclave 3, valve 4, cooling pool 5, autoclave 6, valve 7, cooling pool 8, autoclave 9, valve 10, cooling Pool 11 et al. The ultrasonic container 1, the pump 2, the autoclave 3, the valve 4, the cooling pool 5, the autoclave 6, the valve 7, the cooling pool 8, the autoclave 9, the valve 10 and the cooling pool 11 are connected in sequence through pipelines. Feed inlet, cooling pool 9 is provided with feed outlet.

[0027] Select N-methylpyrrolidone as the organic solvent, add a certain amount of graphite powder and a certain amount of N-methylpyrrolidone into the ultrasonic container 1 from the feed port, and make the graphite powder evenly mixed in the organic solvent by ultrasonication. for 60 minutes. The above-mentioned graphite powder mixed solution in the ultrasonic container 1 is pumped into the autoclave 3, the inlet of the pump 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com