Method and device for preparing nanofiber yarn

A nanofiber and preparation device technology, applied in the field of nanofiber yarns, can solve the problems of poor comprehensive mechanical properties of nanofiber yarns, uneven twist transfer of nanofiber yarns, and difficulty in controlling the twist degree of twisting, so as to achieve enhanced mechanical properties and uniformity. high temperature and reduce air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also shows a flow chart of a method for preparing a nanofiber yarn using the above-mentioned nanofiber yarn preparation device, as Figure 7 shown in Figure 7 In, the preparation method of described nanofiber yarn comprises:

[0068] Step 701, dispensing the spinning liquid, putting the prepared spinning liquid into each syringe of the spinning module, and then installing each syringe in the syringe channel of the syringe pump.

[0069] Among them, the polymers used to prepare the spinning solution include fiber-forming polymers including polyurethane, polyamide, polylactic glycolic acid, silk fibroin, gelatin, collagen, etc.; the solvents used to prepare the spinning solution include distilled water, hexafluoroisopropanol Ethanol, dimethylformamide, tetrahydrofuran, etc.; other additive materials used to prepare spinning solutions include functional materials such as nano-silver, graphene, and ferroferric oxide.

[0070] Step 702, after setting...

Embodiment 1

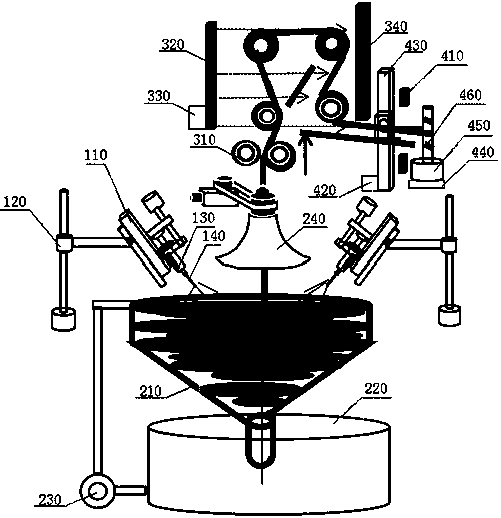

[0083] The preparation device of the nanofiber yarn that this embodiment involves is as Figure 4 shown. Before spinning, dissolve 0.16g of polyurethane (PU, molecular weight: 60000g / mol) in a mixed solvent consisting of 9.2g of dimethylformamide (DMF) and 9.2g of tetrahydrofuran (THF), and stir magnetically at 40°C 12h to obtain PU spinning solution. When spinning, put the PU spinning liquid into the syringes of each injection pump of the spinning module, and then adjust the parameters. The two spinnerets are set in the upper liquid tank of the liquid vortex twisting module, 200mm above the liquid vortex liquid level. At 45° from the liquid surface of the vortex pointing to the center of the vortex, the two spinnerets are located on the diameter of the circular vortex with a distance of 350mm. Both injectors deliver PU spinning liquid to the spinneret at a speed of 0.8ml / h, and both spinnerets apply an electrostatic voltage of +12Kv, so that the PU spinning liquid is jetted...

Embodiment 2

[0085] The preparation device of the nanofiber yarn that this embodiment involves is as Figure 4 shown. Before spinning, the polyurethane of 0.16g (PU, molecular weight is 60000g / mol) and 0.002g ferric oxide (Fe 3 o 4 ) was dissolved in a mixed solvent consisting of 9.2g dimethylformamide (DMF) and 9.2g tetrahydrofuran (THF), and stirred magnetically at 40°C for 12h to obtain PU-Fe 3 o 4 spinning solution. When spinning, the PU-Fe 3 o 4 The spinning solution is respectively loaded into the syringes in the two syringe pumps of the spinning module for spinning. Then adjust the parameters, set the two spinnerets in the upper liquid tank of the liquid vortex twisting module, 200mm directly above the liquid vortex liquid level, and point to the center of the vortex at 45° with the liquid vortex liquid surface, and the two spinnerets are located in the circle On the diameter of the shaped vortex, the distance is 450mm. Both injectors deliver PU-Fe to the spinneret at a spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com