Electrospray device, method of producing solar cell anti-reflection layer by electrospray, and solar cell

A solar cell, electrospray technology, applied in spray discharge devices, circuits, electrical components, etc., can solve the problems of cumbersome operation, difficult to adapt to automatic production, low experimental temperature, etc., and achieves low process environment requirements, wide range of uses, and degree of automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

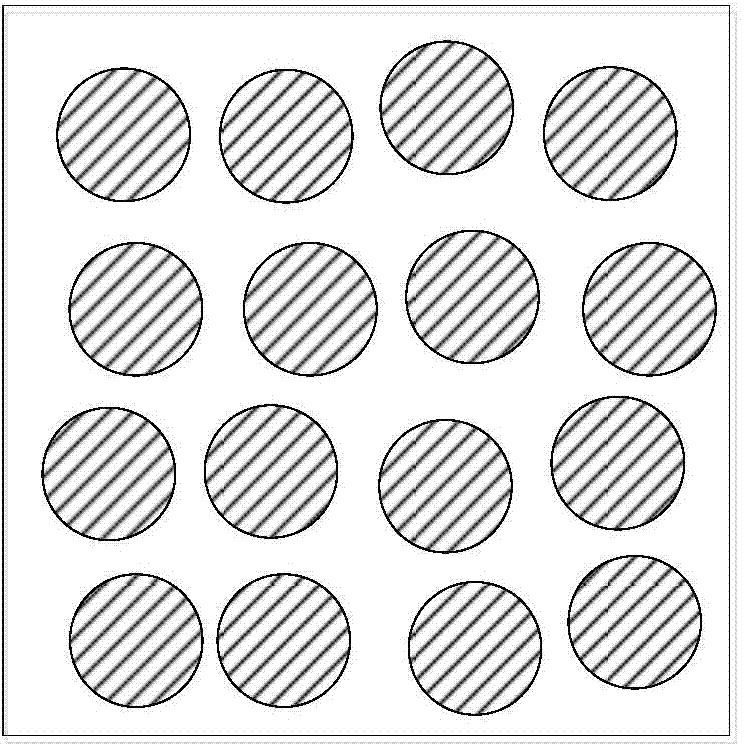

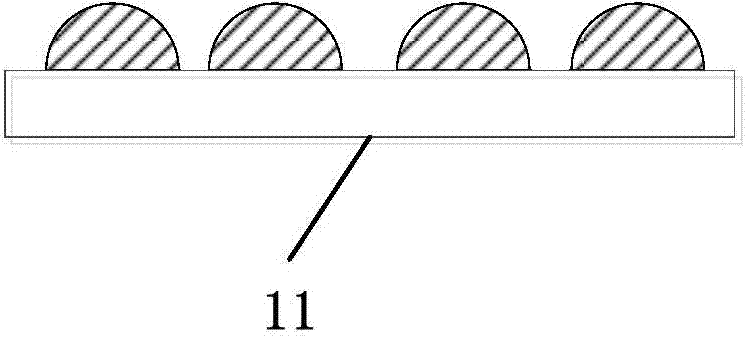

[0034] The anti-reflection layer prepared by the method for preparing the anti-reflection layer of a solar cell provided by the invention has a microstructure of an inverted "nanometer bowl" array. Compared with several traditional techniques, the electrospray technique adopted in the present invention has obvious advantages, specifically as follows:

[0035] (1) The whole process does not require chemical corrosion, does not produce toxic gases or odors, and has little impact on the environment;

[0036] (2) The whole process adopts digital control, and various process parameters such as voltage, spray liquid flow rate, electrode spacing, etc. are easy to control, and automatic production can be realized.

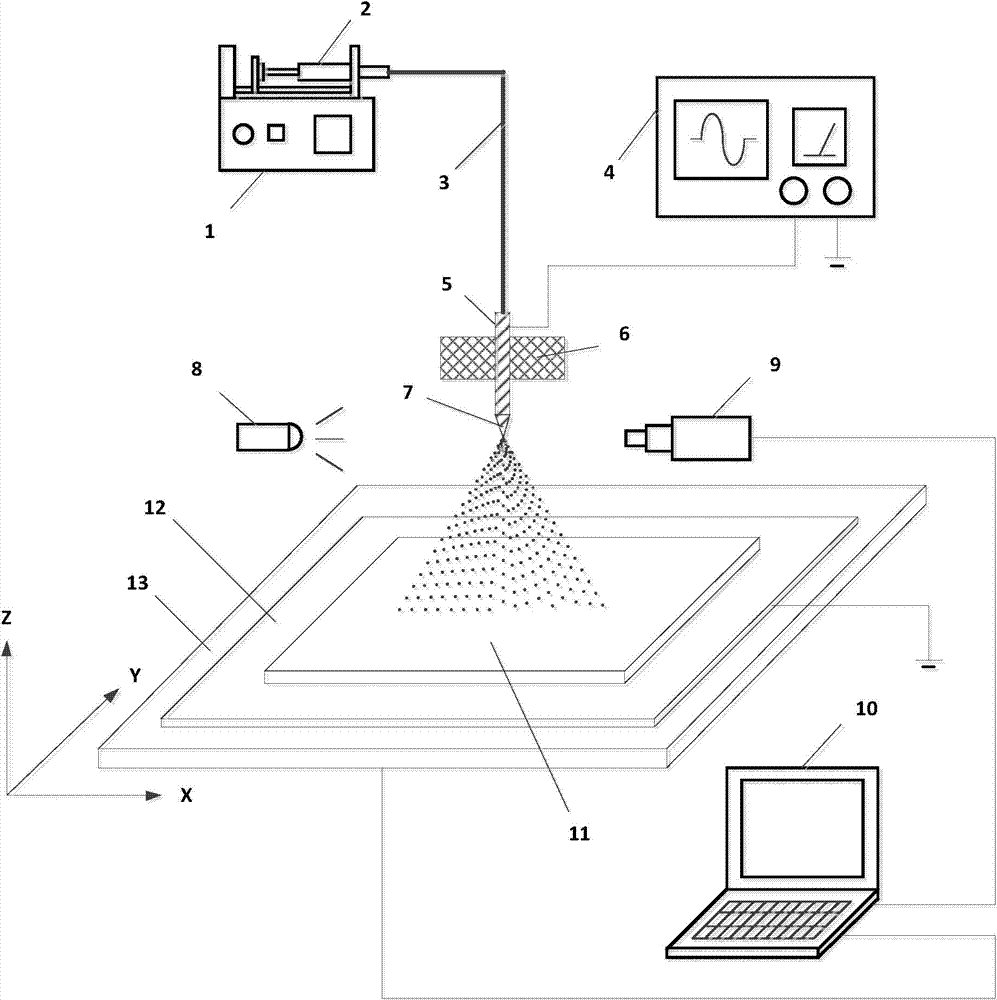

[0037] Such as figure 1 As shown, the device required for the preparation of the solar cell anti-reflection layer inverted "nanobowl" array provided by the present invention includes: a micro-injection pump 1, a syringe 2, a silicone rubber tube 3, a programmable high-vol...

Embodiment 1

[0062] Embodiment 1: Both the spray liquid and the TCO substrate 11 are made of nano-FTO material. The specific preparation process of the inverted "nano bowl" anti-reflection layer prepared by electrospray technology is as follows:

[0063] (1) carry out surface modification to the FTO substrate that area is 10cm * 10cm, make the substrate surface have hydrophobicity;

[0064] (2) configure nano FTO solution, its mass percent concentration is 5%, as the spray liquid of electrospray, use magnetic stirrer to stir 2~4 hours at 30 ℃, stand still for 0.5 hour;

[0065] (3) Start the micro-injection pump 1, and its driving flow is 5uL / min, and the nano-FTO solution is delivered to the metal nozzle 5 through the silicon rubber tube 3;

[0066] (4) turn on the PC control unit 10 successively, the cold light source 8 and the CCD high-speed camera 9;

[0067] (5) Start the programmable high-voltage generator 4, whose output voltage is 6kV, and observe the shape, size and density dist...

Embodiment 2

[0069] Embodiment 2: Both the spray liquid and the TCO substrate 11 are made of nanometer AZO material. The specific preparation process of the inverted "nano bowl" anti-reflection layer prepared by electrospray technology is as follows:

[0070] (1) surface-modify the AZO substrate with an area of 10cm×10cm to make the surface of the substrate hydrophobic;

[0071] (2) Configure nano-AZO solution, its mass percentage concentration is 5%, as the spray liquid of electrospray, use magnetic stirrer to stir for 2~4 hours at 30 ℃, stand still for 0.5 hour;

[0072] (3) Start the micro-injection pump 1, and its driving flow is 5uL / min, and the nano-ITO solution is delivered to the metal nozzle 5 through the silicon rubber tube 3;

[0073] (4) turn on the PC control unit 10 successively, the cold light source 8 and the CCD high-speed camera 9;

[0074] (5) Start the programmable high-voltage generator 4, whose output voltage is 6KV, and observe the shape, size and density distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com