Wet-strength waste paper pulping method

A waste paper, wet strength technology, applied in the processing of waste paper, paper making, paper recycling, etc., can solve the problems of low fiber recovery rate, long disintegration time, high energy consumption for pulping, etc., to reduce dissociation time and increase penetration. , improve the pulping efficiency and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Effect of different enzymes on the complete disintegration time of wet strength waste paper

[0048] (1) Test materials

[0049] Waste paper: Broken paper from a household paper mill in Jiangmen, Guangdong, containing 1-5% polyamide epichlorohydrin resin (PAE) wet strength agent;

[0050] Enzyme:

[0051] 1. Amidase and nitrilase: purchased from U.S. SigmaAldrich Company (St.Louis, MO), which is derived from Pseudomonas aeruginosa, expressed in E.Coli after recombination;

[0052] 2. Serine protease: produced by Guangzhou Ruichen Shengda Biotechnology Co., Ltd.; TM The test product WS-8001, derived from Bacillus, has an activity of 3U / g protein;

[0053] 3. Amidase: Produced by Guangzhou Ruichen Shengda Biotechnology Co., Ltd.; TM The test product WS-8002 is a variety of biological enzymes derived from Lactobacillus, mainly polyamidase; its polyamidase activity is according to the literature (Heumann et al., Biotechnology & Bioengineering, 2009, 102, 1003-...

Embodiment 2

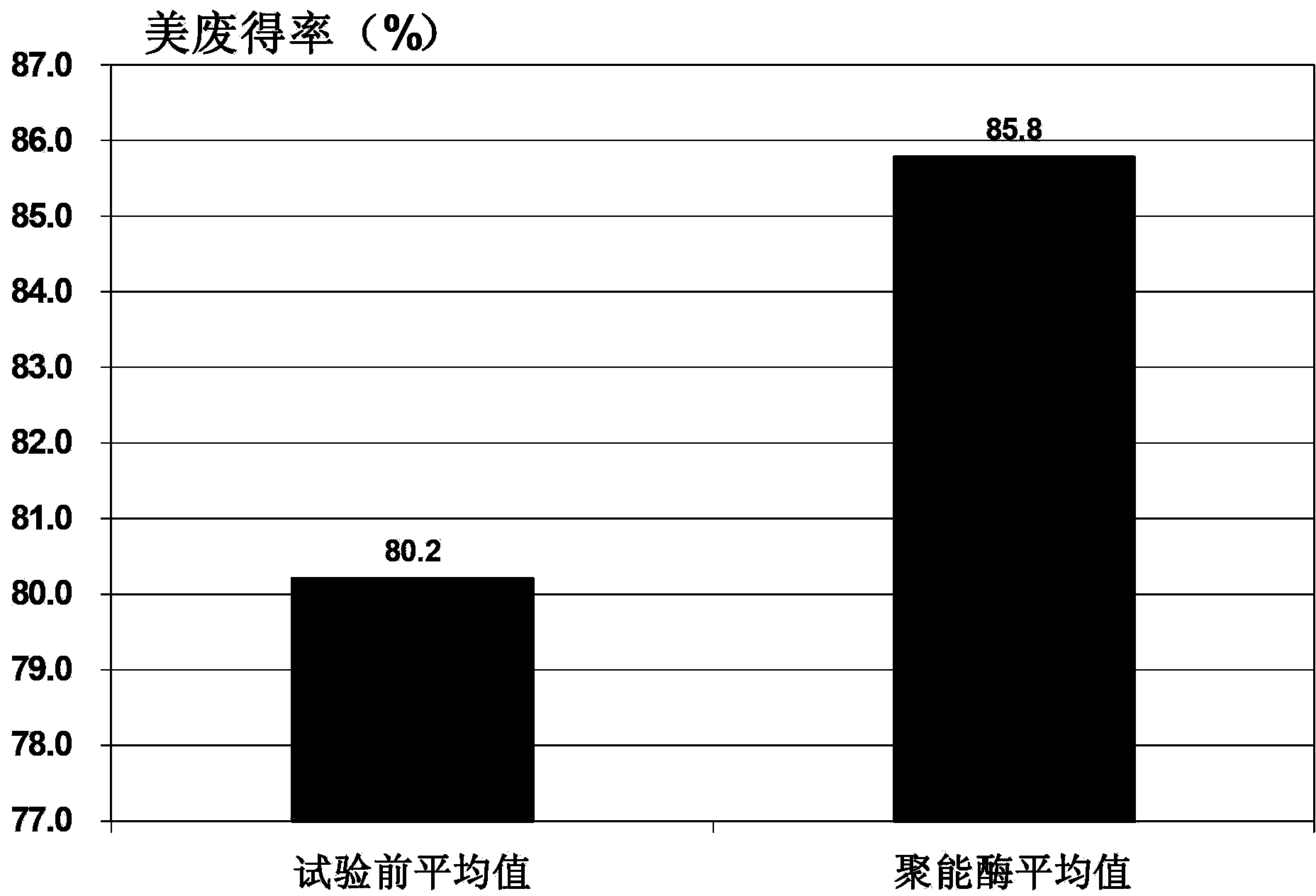

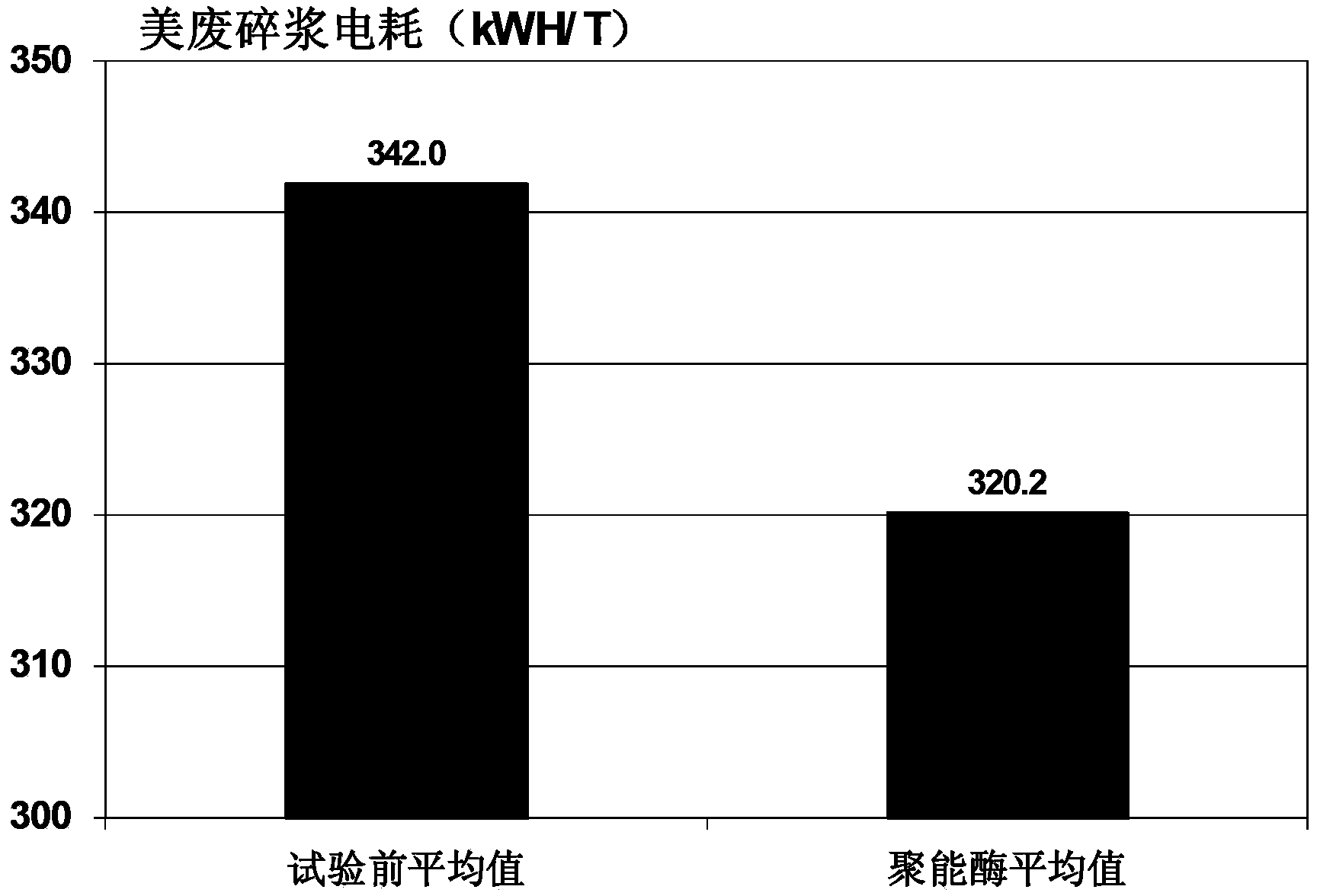

[0071] Embodiment 2 comparative analysis adds the amidase of different amounts, the rate of recovery of film rubbish amount, effective fiber and fine fiber

[0072] (1) Test materials

[0073] Waste paper: coated food packaging paper with high wet strength;

[0074] Amidase: Produced by Guangzhou Ruichen Shengda Biotechnology Co., Ltd.; TM The test product WS-8002 is a variety of biological enzymes derived from Lactobacillus (Lactobacillus), mainly polyamidase (polyamidase). Said method was determined to be 1.1U / g.

[0075] (2) The specific steps of the pulping method are as follows:

[0076] (1) Cut waste paper into squares with a width of about 3×3cm, put them into water at a temperature of 40°C, stir and mix to obtain waste paper slurry; the concentration of waste paper is 20%;

[0077] (2) Adjustment step (1) The temperature of the waste paper slurry is 40°C, the pH is 7-8, add amidase according to the weight of the waste paper (see Table 2), stir for 2 minutes, stop, ...

Embodiment 3

[0083] Example 3 Comparative analysis of the effects of adding caustic soda (control group) and biological enzymes (test group) on disintegration time and paper

[0084] In order to improve the strength, especially the stiffness, of paper towels during production, a large amount of wet strength agent needs to be added. Due to the presence of high wet strength agents, it is extremely difficult to pulp broken / broken paper. Even if the pulping time is prolonged, it still contains a large number of pulp lumps, which requires high-temperature pulping (75°C) and the addition of a large amount of caustic soda and sodium hypochlorite (per Ton waste paper needs to add 20-100 kg).

[0085] (1) Test materials

[0086] Waste paper: paper towels;

[0087] Amidase: Produced by Guangzhou Ruichen Shengda Biotechnology Co., Ltd.; TM The test product WS-8002 is a variety of biological enzymes derived from Lactobacillus (Lactobacillus), mainly polyamidase (polyamidase). Said method was deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com