Method for pulping mixed broad-leaved woods

A technology for hardwood and pulping, which is applied in the directions of pulping with inorganic alkali, pulp bleaching, post-processing of cellulose pulp, etc., can solve the problems of difficult selection of process technology, many kinds of raw materials, and large differences in characteristics, so as to reduce environmental pollution. , reduce energy consumption, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

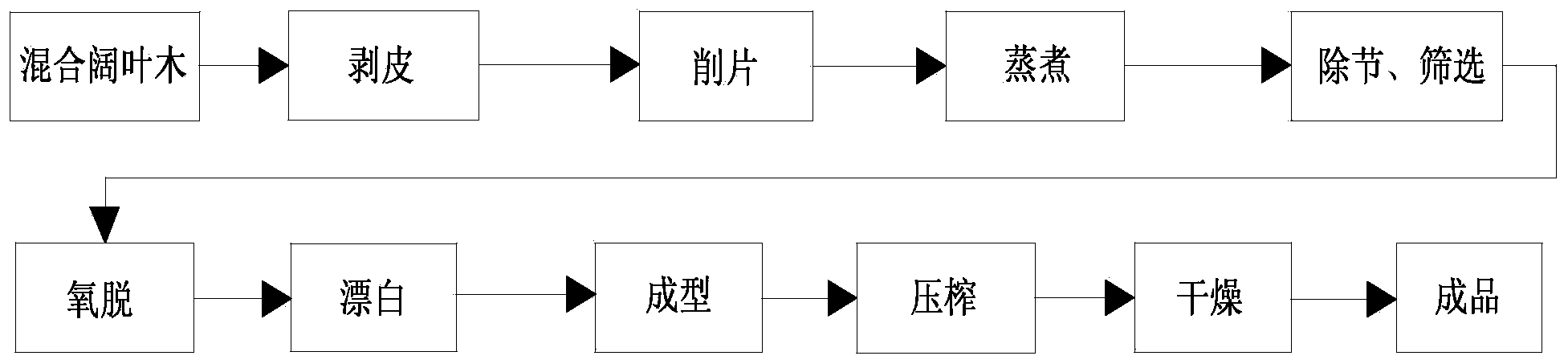

[0024] The method for mixing hardwood pulp of the present invention comprises the following steps:

[0025] S010, peeling

[0026] The broad leaves after harvesting are peeled in different ways according to different diameters and sizes;

[0027] S020, shavings

[0028] Chipping the hardwood that meets the requirements after peeling in the above step S010 with a chipper to obtain qualified wood chips;

[0029] S030. Cooking

[0030] Feed the qualified wood chips chipped in the above step S020 into the cooking pot, cook at a cooking temperature of 170°C to 175°C, use an alkali amount of 25% to 27%, H-factor 1500 to 2000, and DF1. 260 minutes;

[0031] S040. Removal of festivals

[0032] That is to say, the slurry cooked in the above step S030 is subjected to knot removal treatment at a feed concentration of 2% to 4%, a slurry concentration of 2% to 3.5%, a normal pressure difference of 0 to 40Kpa, and a working pressure of 150 to 500Kpa;

[0033] S050. Screening

[0034]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com