Pulper with automatic paper and plastic separating function

An automatic separation and pulping machine technology, applied in raw material separation, papermaking, paper recycling, etc., can solve the problems of large resistance, slow pulping speed, power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

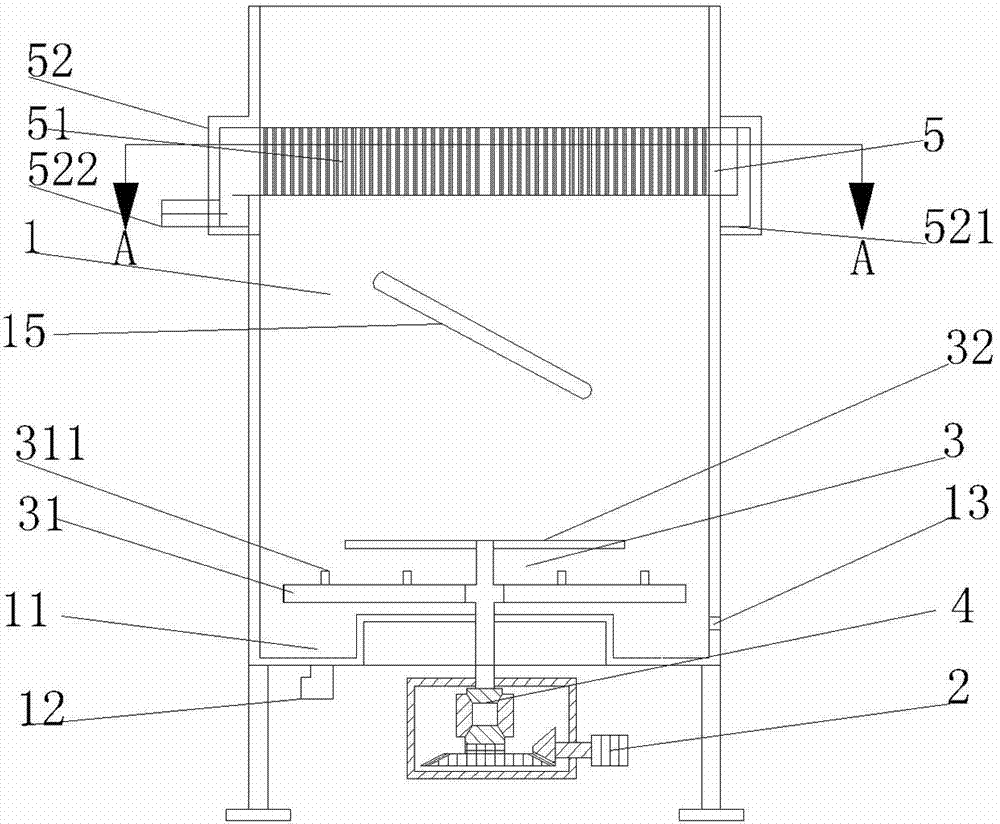

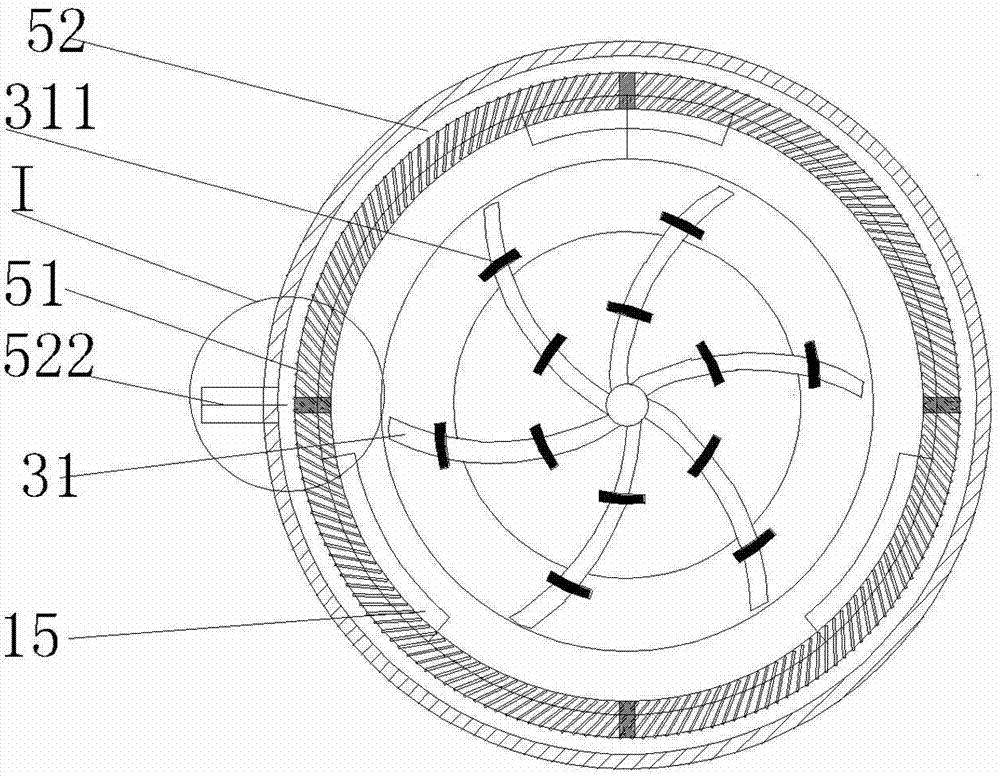

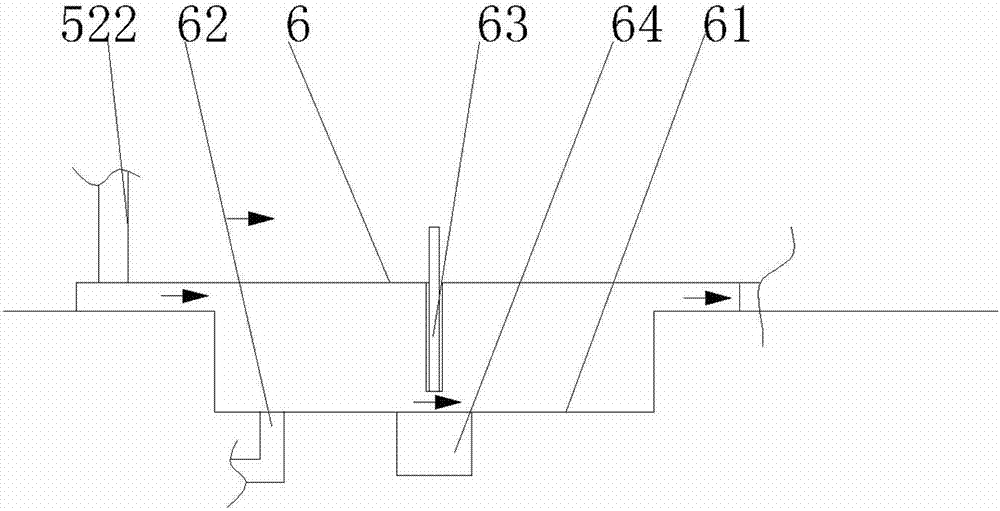

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a new paper-plastic automatic separation pulping machine is characterized in that it includes a cylinder body 1, a motor 2 disposed below the cylinder body 1, a stirring knife device 3 disposed at the bottom of the cylinder body 1, and a stirring knife device disposed on the bottom of the cylinder body 1. 3 and the reduction box 4 between the motor 2, the bottom of the cylinder 1 is provided with an annular sediment tank 11 for sedimentation and collection of heavy impurities, the bottom of the sediment tank 11 is provided with a slag outlet 12, and the bottom of the cylinder 1 A water inlet 13 is provided, and the water inlet 13 is located below the stirring tool device 3. The upper part of the cylinder body 1 is provided with an annular discharge port 5, and the annular discharge port 5 is evenly distributed with several louver filter sieves 51. An annular collection bag 52 is arranged outside the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com