Process for preparing slurry with wide granularities distribution by parallel grinders

A technology of size distribution and slurry, which is applied in the field of preparing slurry with wide particle size distribution in parallel with mills, can solve the problem that there is no method to simultaneously solve high concentration and high stability of slurry, reduce contact points, and cannot solve slurry stability To achieve the effect of widening particle size distribution, convenient operation and improving pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

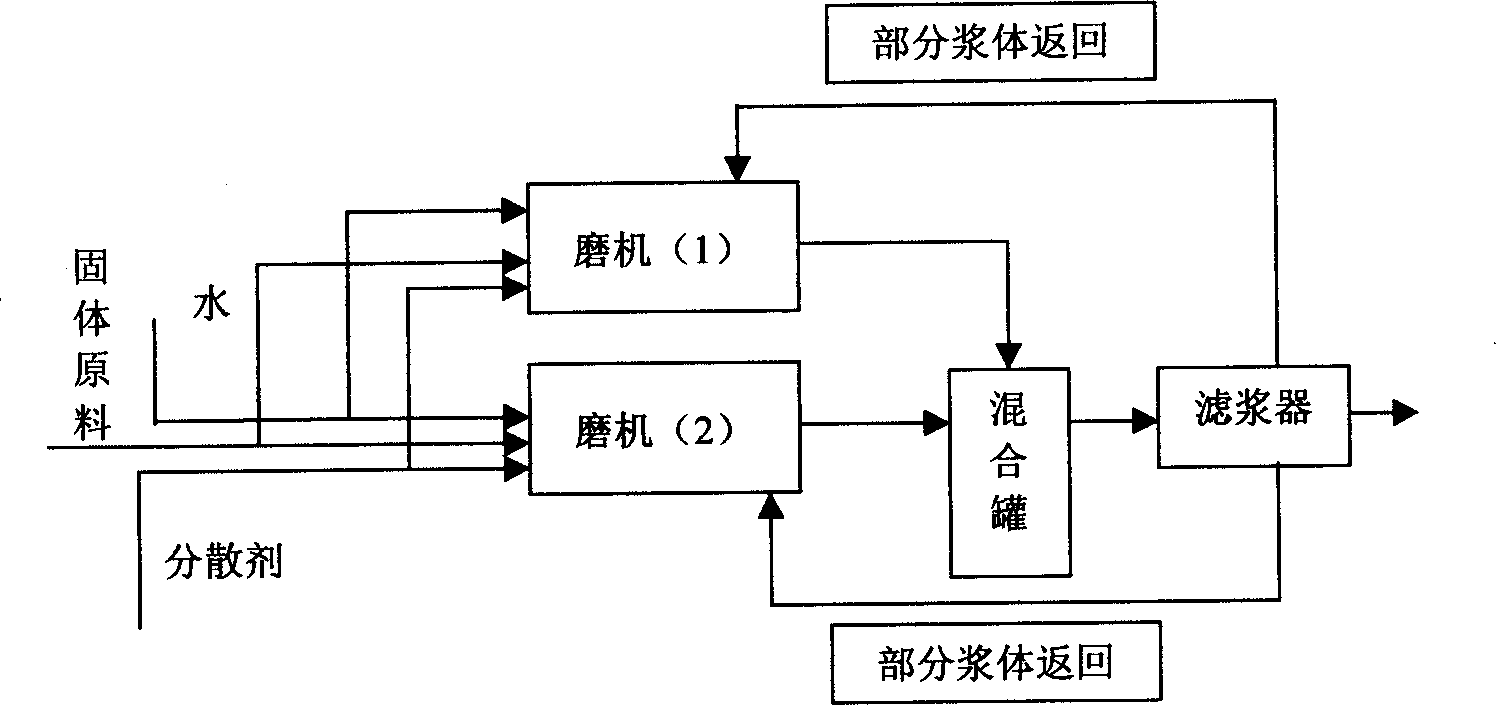

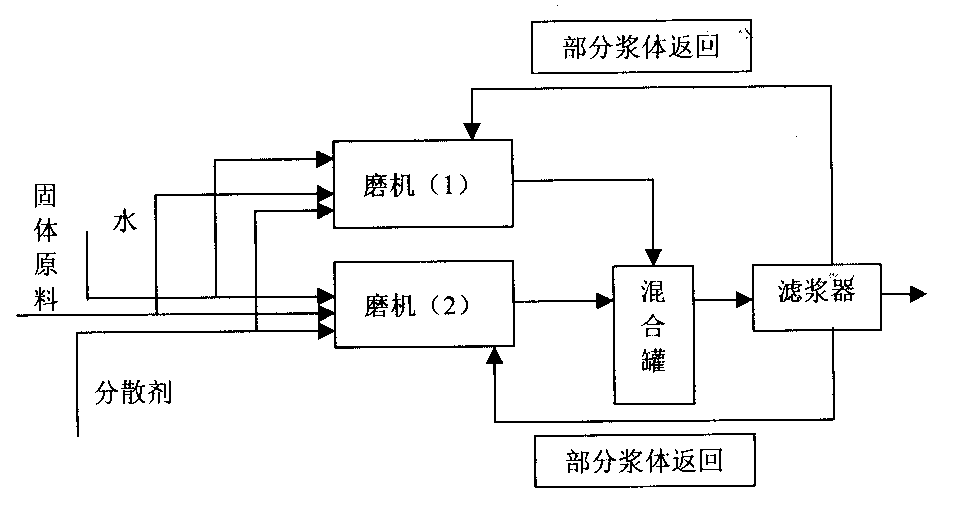

[0011] Embodiment 1. prepares the method for Xinglongzhuang 2# clean coal water slurry of wide particle size distribution with mill parallel connection method.

[0012] The mass percentage of coal fed into the vibration mill and the ball mill is 10:90 to 50:50 to prepare the coal water slurry. Take the Xinglongzhuang 2# clean coal feeding mass percentage of vibratory mill and ball mill as 30:70 to prepare coal water slurry with a wide particle size distribution of 4.0kg / h as an example: the vibratory mill adopts 2MZG-38 type, and the load is 1.4kg / h, the amount of coal input is 0.83kg / h, the amount of dispersant NDF added is 0.02kg / h (25wt%), and the amount of water added is 0.55kg / h. 72.0 wt% filter cake. The ball mill adopts XMB-Ф240×330 type, with a volume of 13.57L, a load of 2.88kg / h, a coal input of 1.95kg / h, a dispersant NDF of 0.02kg / h (50wt%), and water of 0.90kg / h. The slurry made by the ball mill is mixed with the filter cake made by the vibrating mill after suc...

Embodiment 2

[0015] Example 2. A method for preparing Qilu petroleum coke water coke slurry with a wide particle size distribution by a mill parallel method.

[0016] The mass percentage of the coke feed in the vibratory mill and the ball mill is 15:85 to 35:65 to prepare water coke slurry. Take the Qilu petroleum coke feeding mass percentage of vibrating mill and ball mill as 25:75, and prepare water coke slurry with a wide particle size distribution of 4.0kg / h as an example: the vibrating mill adopts 2MZG-38 type, and the load is 1.24kg / h h, the amount of coke thrown is 0.74kg / h, the amount of dispersant NDF added is 0.01kg / h (50wt%), and the amount of water added is 0.49kg / h. The prepared slurry has a concentration of 72.0wt after suction filtration by a dehydrator % of filter cake. The ball mill adopts XMB-Ф240×330 type, with a volume of 13.57L, a load of 3.1kg / h, a coke casting amount of 2.23kg / h, a dispersant NDF of 0.03kg / h (50wt%), and water of 0.84 kg / h. The slurry made by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com