Method for efficiently preparing large-volume semi-solid thick liquid through compounding process

A semi-solid slurry and composite process technology, applied in the field of metal semi-solid processing, can solve the problems of unsuitable large-volume semi-solid slurry preparation, unstable pulping process, and difficult industrialization promotion, and achieve stable and reliable pulping process. Easy to promote and apply in industrialization, high pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

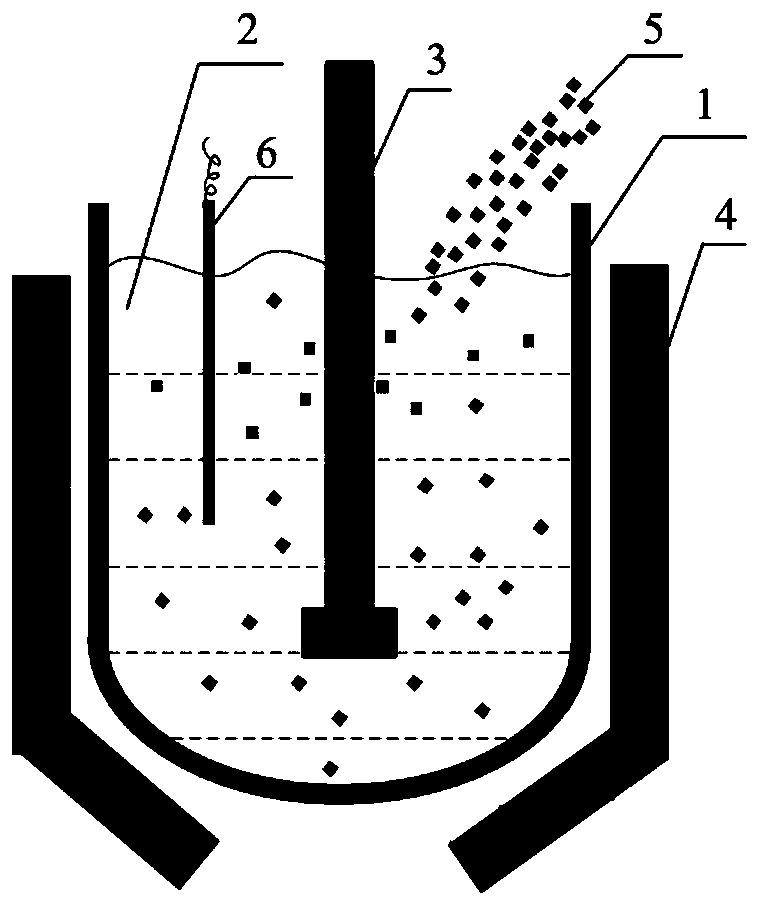

[0047] A356 aluminum alloy (liquidus 615 ℃, solidus 555 ℃) semi-solid slurry with a quality of 40 kg prepared by the present invention, the schematic diagram of the composite process for preparing large-volume semi-solid slurry is as follows figure 2 shown.

[0048] The preparation works as follows:

[0049] The container 1 is a crucible, and the A356 aluminum alloy melt 2 (40kg) with a temperature of 660° C. is scooped out with the crucible;

[0050] The melt stirring device adopted is a mechanical stirring device 8, and the melt disturbing device adopted is a three-phase AC induction electromagnetic stirring coil 7. The specific mechanical stirring parameters are a stirring rod with an outer diameter of 80 mm, made of graphite, and a stirring speed of 600 r / min. The electromagnetic disturbance parameters are 380V three-phase alternating current, power 2.2KW, and current 20A; start the mechanical stirring 8 and the three-phase alternating current induction electromagnetic s...

Embodiment 2

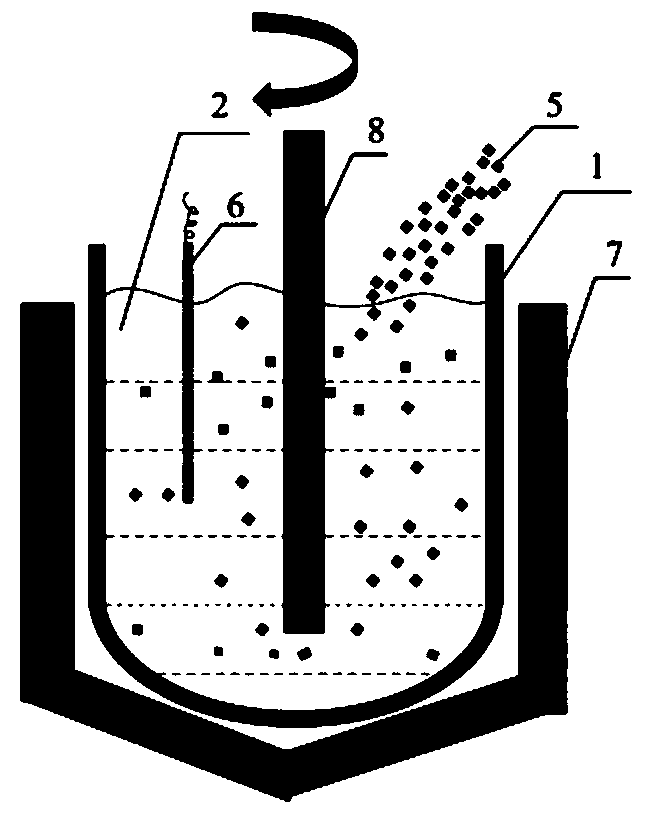

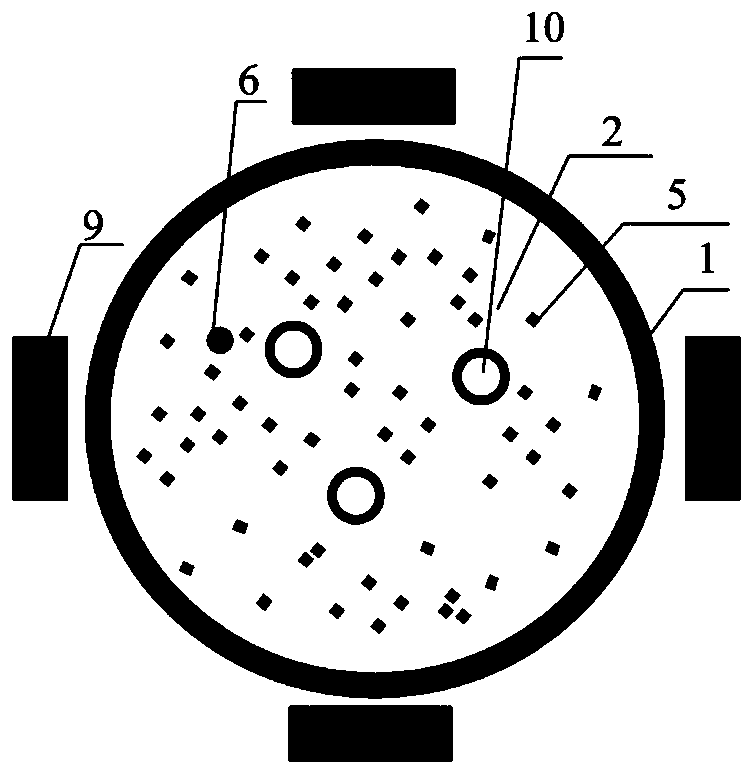

[0053] Embodiment 2: Adopt the semi-solid slurry of AlSi8 aluminum alloy (liquidus line 625 ℃, solidus line 563 ℃) that the mass of the present invention is prepared to be 62kg, the schematic diagram of compound process preparation large-volume semi-solid slurry is as follows image 3 shown. Proceed as follows:

[0054] (1-1) The container 1 is a crucible, and 50 kg of AlSi8 aluminum alloy melt 2 at a temperature of 670° C. is scooped out from the crucible and placed inside the melt disturbance device 4 .

[0055] (1-2) The melt stirring device 3 adopted is an ultrasonic stirrer 10, and the number of the ultrasonic stirrer 10 is 3, and the melt disturbing device 4 adopted is an electromagnetic stirrer 9, and the number of the electromagnetic stirrer 9 is 4, specifically The ultrasonic stirring parameters are ultrasonic power 1.5KW, ultrasonic frequency is 20kHz, the specific electromagnetic disturbance parameters are power 12KW, frequency 15Hz; start the ultrasonic stirring a...

Embodiment 3

[0058] Embodiment 3: adopt the present invention to prepare the ZnAl9Cu2 zinc alloy (liquidus line 405 ℃, solidus line 345 ℃) semi-solid slurry that adopts the present invention to prepare quality, the synoptic diagram of composite process preparation large-volume semi-solid slurry is as follows Figure 4 shown. Proceed as follows:

[0059] (1-1) Container 1 is a crucible, and 95 kg of ZnAl9Cu2 zinc alloy melt 2 at a temperature of 480° C. is scooped out from the crucible and placed inside the melt disturbance device 4 .

[0060] (1-2) The melt stirring device 3 used is mechanical stirring, the number of mechanical stirring rods 8 is 3, the melt disturbing device 4 adopted is a vibrator 11, and the specific mechanical stirring parameters are a stirring speed of 1000r / min, specifically The vibration parameter is a vibration frequency of 50 Hz; start the mechanical stirring rod 8 and the vibrator 11 to directly stir the zinc alloy melt 2 in the crucible 1 and indirectly stir th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com