Automatic royal jelly acquisition device

A royal jelly and automatic technology, applied in the field of agricultural engineering, can solve the problems of no significant improvement in pulp extraction efficiency, low efficiency of wax cutting and insect extraction, and high residual rate of royal jelly, so as to save manual insect extraction, less residual royal jelly, and manual consumption little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

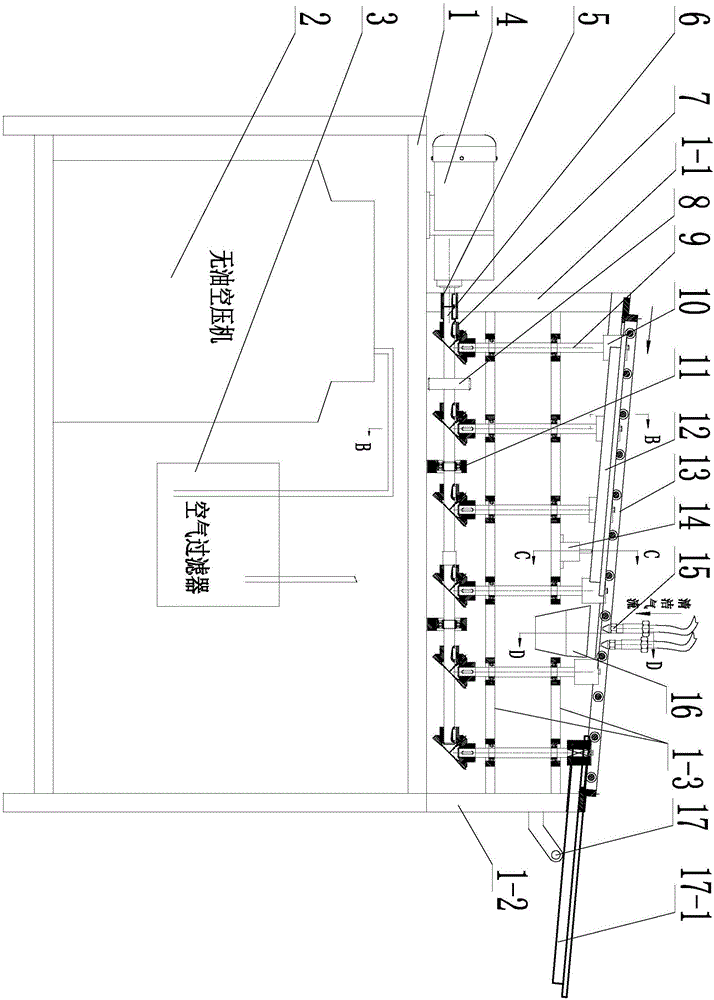

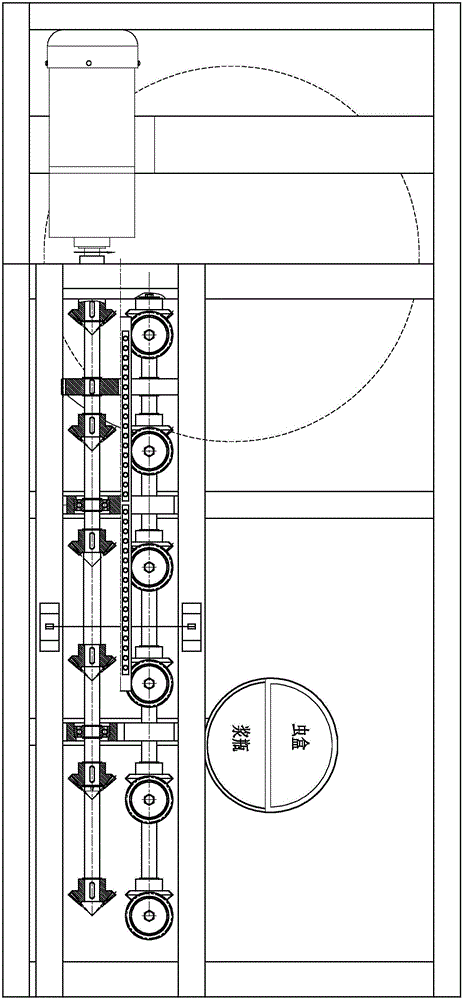

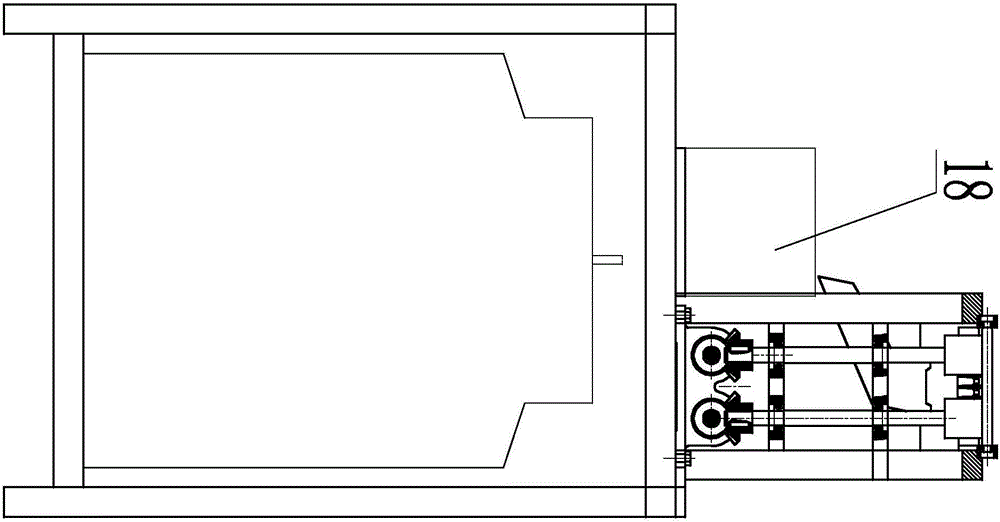

[0043] Example 1, see figure 1 —— Figure 18 A kind of royal jelly automatic extracting device of the present invention comprises a working platform 1, a pulp production bar 12, a transmission device for transmitting the pulp production bar 12, a wax cutting device 14 for cutting the beeswax on the pulp production bar 12 in the transmission process, for After the wax is cut, royal jelly and larvae are blown out from the air blowing device in the bar that produces pulp, larvae are separated from royal jelly by the pulpworm separation device 16 and are used to collect the pulpworm collection device of royal jelly and larvae after separation respectively; Wherein,

[0044] The transmission device includes a driving cross shaft 6, a driven cross shaft 6-1 and a driving device for driving the driving cross shaft 6 to rotate. A row of driving bevel gears 7 and at least one Drive cylindrical gear 8, a row of driven bevel gear 7-1 and driven cylindrical gear 8-1 supporting the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com