Soybean milk making method of rapid soybean milk maker

A production method and a technology of a pulping machine, which are applied to dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of water resource waste, increased difficulty, and excessive water resources, so as to reduce water resources, improve utilization, and avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

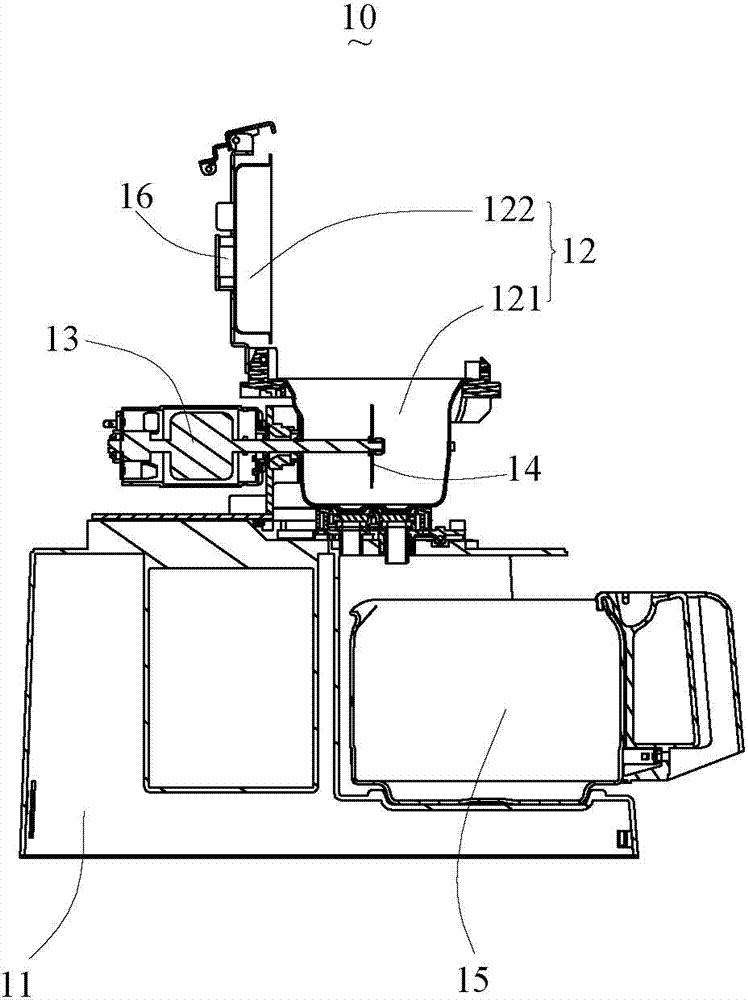

[0036] see figure 1 A schematic diagram of the rapid pulper, the rapid pulper 10 includes a machine base 11 , a small space pulverizer 12 , a heating device (not shown in the figure), a motor 13 , a pulverizer 14 and a pulp receiving cup 15 . The small space pulverizer 12 and the motor 13 are arranged on the machine base 11 . This heating device heats the small space shredder 12 . The motor 13 drives the crushing cutter 14 to rotate. The pulverizer 14 is located inside the small space pulverizer 12 . The small space pulverizer 12 is also provided with a pressure control valve 16 .

[0037] Described small space pulverizer 12 comprises the cylinder block 121 that is provided with opening and the cylinder head 122 that closes cylinder body 121 openings, is provided with sealing ring (not shown) between cylinder head 122 and cylinder body 121, so, cylinder body 121 and the cylinder head 122 form an airtight container. In this embodiment, the motor 13 is located on one side o...

Embodiment approach 2

[0053] The difference between the soybean milk production method of the described quick pulper and the first embodiment is:

[0054] The crushing stage increases the process of injecting water into the pulp cup 15, especially in the later stage of the crushing stage, injecting water with a volume of V2 into the pulp cup, so that the overlap in time shortens the pulping cycle. The volume of the capacity V2 depends on the ratio of material to water in the preheating stage. When the ratio is larger, it means that the concentration is higher, so the volume of the capacity V2 is also larger.

[0055] The step of blending is added in the slurry discharge stage: the slurry / paste in the small space pulverizer 12 is discharged under pressure into the slurry receiving cup 15 and the water in the slurry receiving cup 15 is reconciled and homogeneous, so that the discharged slurry can be effectively used The pressure during paste / pasting is reconciled to realize mixing for the first time ...

Embodiment approach 3

[0058] The difference between the soybean milk production method of the described quick pulper and the first embodiment is:

[0059] During the slurry discharge stage, water is injected into the small space pulverizer 12 at the same time, and the slurry / paste in the small space pulverizer 12 is squeezed out by injecting water into the small space pulverizer 12, thus reducing the size of the small space. The slurry in the pulverizer 12 remains.

[0060] In this implementation manner, other structures and beneficial effects are consistent with those of the implementation manner, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com