Wide range continuous diluter

a diluter and wide-range technology, applied in the direction of instruments, specific gravity measurement, mechanical means, etc., can solve the problems of inaccurate characterization of emissions, low dilution ratio, and low dilution range of dilution systems employing typical traditional partial flow diluters, so as to reduce the residence time of the flow, reduce the loss of small particles, and reduce the effect of dilution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

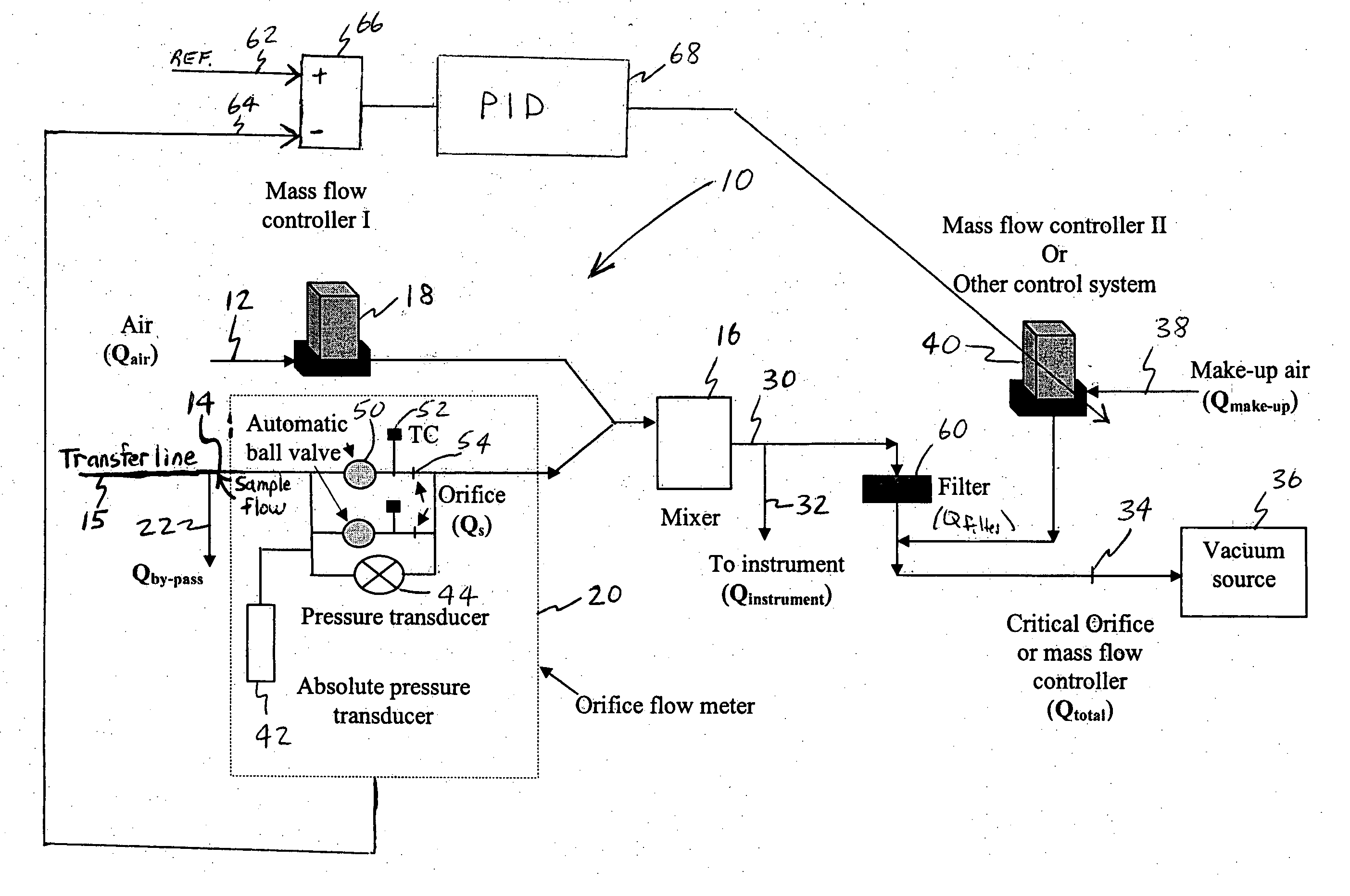

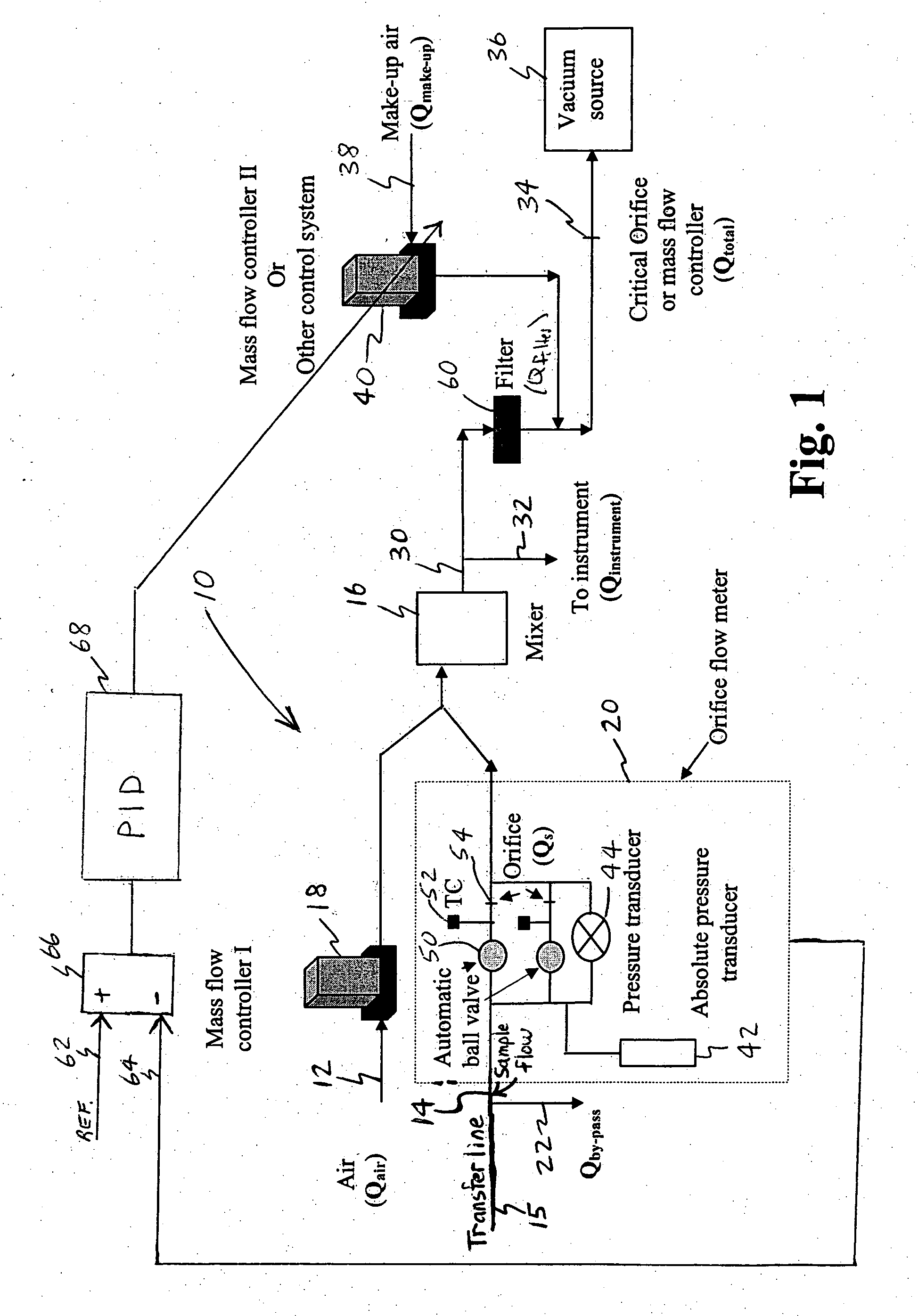

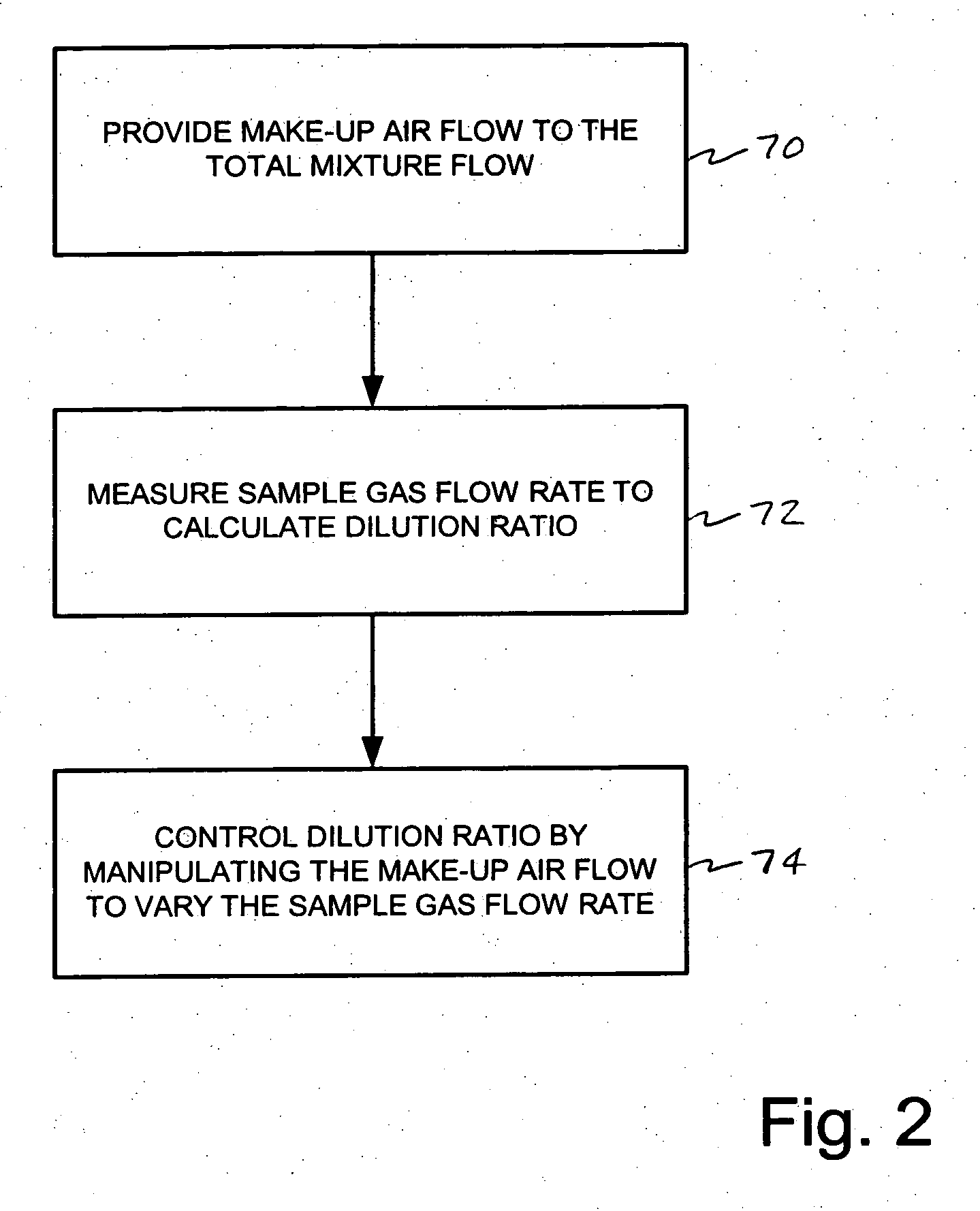

[0018] In FIG. 1, the preferred embodiment of the wide range continuous diluter is generally indicated at 10. A dilution gas inlet 12 receives a dilution gas, and a sample gas inlet 14 receives a sample gas. A mixer 16 is connected to dilution gas inlet 12 and sample gas inlet 14 for receiving and mixing the gases at a dilution ratio. The flow rate of the dilution gas is controlled by mass flow controller 18. Orifice flow meter 20 measures the sample gas flow rate. By-pass flow outlet 22 is provided upstream of flow meter 20 to reduce the residence time of the sample gas flow through the transfer line 15, which connects inlet 14 to the expected sampling source, for example, engine exhaust.

[0019] Mixer 16 has outlet 30, and instrument flow outlet 32 is arranged to provide a well-defined flow into the instrument. The gas mixture flows at a controlled rate provided by critical orifice 34 and vacuum source 36. Critical orifice 34 may alternatively be a mass flow controller. Make-up gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

| gas flow rate | aaaaa | aaaaa |

| residence time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com