Fluorosilicone material for super-hydrophobic coating and its preparation method and use method

A technology of a super-hydrophobic coating and an application method, applied in the field of fluorosilicon materials and their preparation, can solve the problem of high preparation cost of the coating, and achieve the effects of good hydrophobic effect, simple preparation method and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

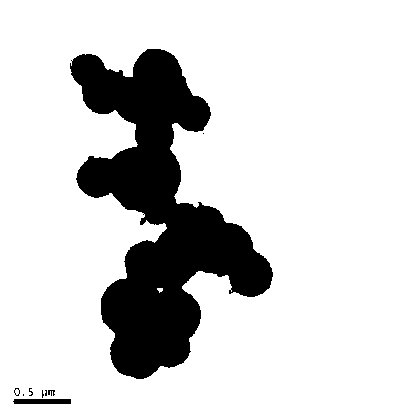

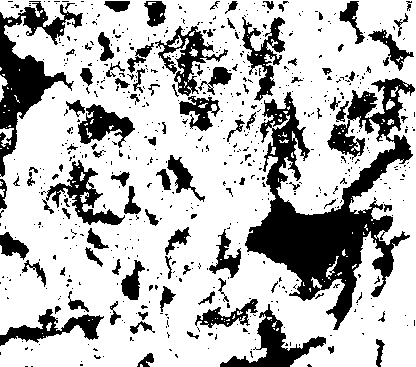

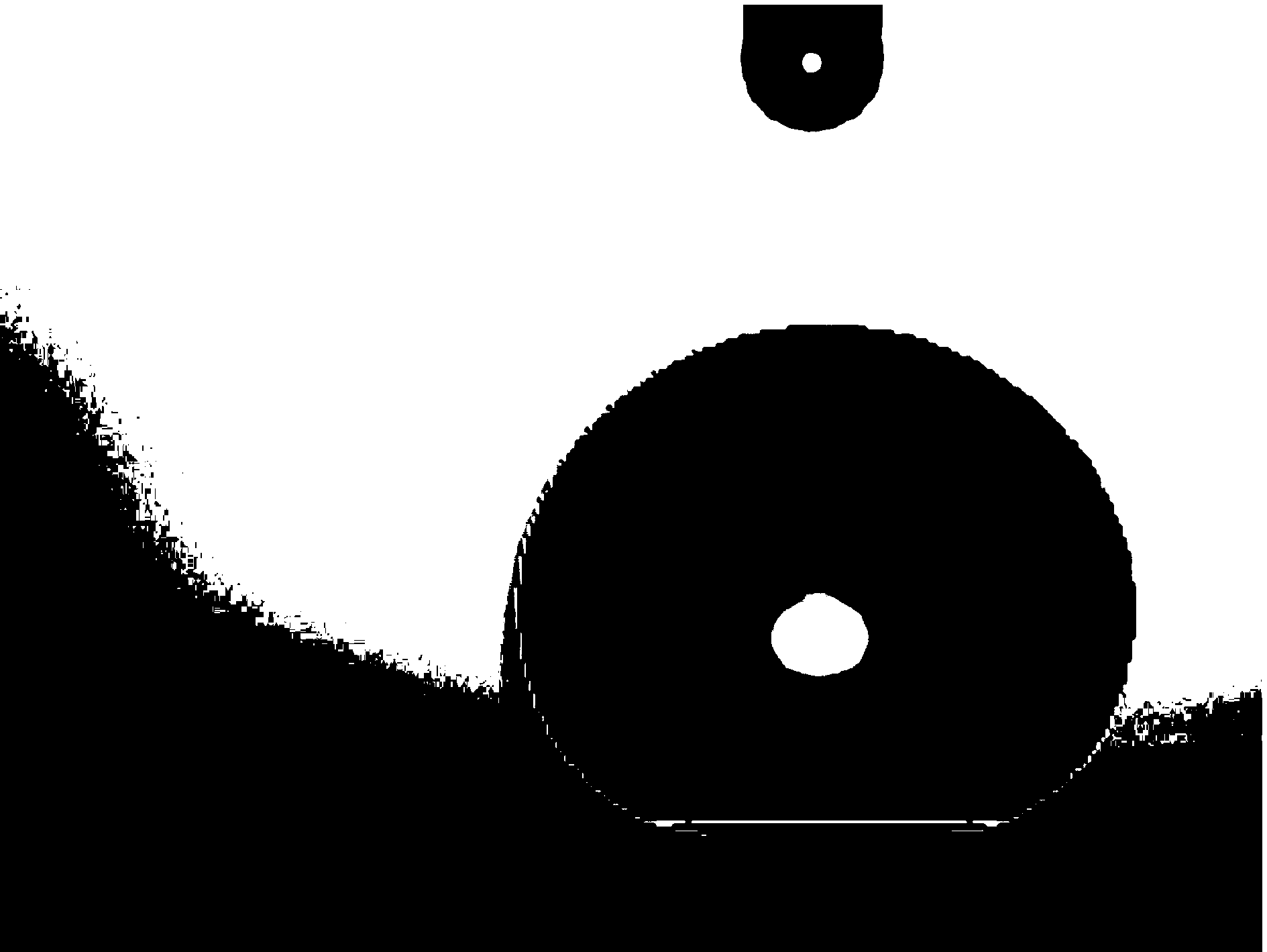

Image

Examples

Embodiment 1

[0029] A fluorosilicon material for superhydrophobic coating, which is prepared from fluorinated nano-silica sols with average particle diameters of 150nm and 400nm respectively.

[0030] The above-mentioned preparation method for the fluorosilicon material of superhydrophobic coating, it comprises the steps:

[0031] (1) Preparation of fluorinated nano-silica sol A with the first particle size: Weigh 3 mL of tetraethyl orthosilicate, 100 mL of absolute ethanol, H 2 O 0.5mL, 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane 1mL, diethyldichlorosilane 1mL, add ammonia water 1mL, stir at reaction temperature 25°C for 1h, and the obtained average particle size is 150nm fluorinated nano silica sol A;

[0032] (2) Preparation of fluorinated nano-silica sol B with the second particle size: Weigh 3 mL of tetraethyl orthosilicate, 100 mL of absolute ethanol, H 2 O 0.5mL, 1H,1H,2H,2H-perfluorooctyltriethoxysilane 1mL, diethyldichlorosilane 1mL mixed, add ammonia water 1mL, stir at reactio...

Embodiment 2

[0040] A fluorosilicon material for superhydrophobic coating, which is prepared from fluorinated nano-silica sols with average particle diameters of 50nm and 250nm respectively.

[0041] The above-mentioned preparation method for the fluorosilicon material of superhydrophobic coating, it comprises the steps:

[0042] (1) Preparation of fluorinated nano-silica sol A with the first particle size: Weigh 1 mL of tetraethyl orthosilicate, 60 mL of methanol, H 2 O 0.1mL, 1H,1H,2H,2H-perfluorooctyltriethoxysilane 0.1mL, diphenyldichlorosilane 0.1mL, add ammonia water 1mL, stir at reaction temperature 30°C for 1h to obtain the average particle size Fluorinated nano-silica sol A with a diameter of 50nm;

[0043] (2) Prepare fluorinated nano-silica sol B of the second particle size: weigh 3 mL of tetraethyl orthosilicate, 50 mL of methanol, H 2 O 0.5mL, 1H,1H,2H,2H-perfluorooctyltriethoxysilane 1mL, diphenyldichlorosilane 0.5mL after mixing, add ammonia water 1mL, stir at the reaction...

Embodiment 3

[0050] A fluorosilicon material for superhydrophobic coating, which is prepared from fluorinated nano-silica sols with average particle diameters of 60nm and 300nm respectively.

[0051] The above-mentioned preparation method for the fluorosilicon material of superhydrophobic coating, it comprises the steps:

[0052] (1) Preparation of fluorinated nano-silica sol A with the first particle size: Weigh 3 mL of tetrahydrofuran, 100 mL of tetrahydrofuran, and 2 O 0.5mL, 1H,1H,2H,2H-perfluorooctyltriethoxysilane 0.5mL, diphenyldichlorosilane 0.5mL, add ammonia water 1mL, stir at reaction temperature 30°C for 3h to obtain the average particle size Fluorinated nano-silica sol A with a diameter of 60nm;

[0053] (2) Preparation of fluorinated nano-silica sol B with the second particle size: Weigh 5 mL of tetrahydrofuran, 100 mL of tetrahydrofuran, and 2 O 0.5mL, 1H,1H,2H,2H-perfluorooctyltriethoxysilane 2mL, diphenyldichlorosilane 0.5mL after mixing, add glacial acetic acid 1mL, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Antenna | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com