Quantitative material conveying device applied to packaging of particle bags

A technology of particle bags and measuring cylinders, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of low packaging efficiency and troublesome operation, and achieve the effect of improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

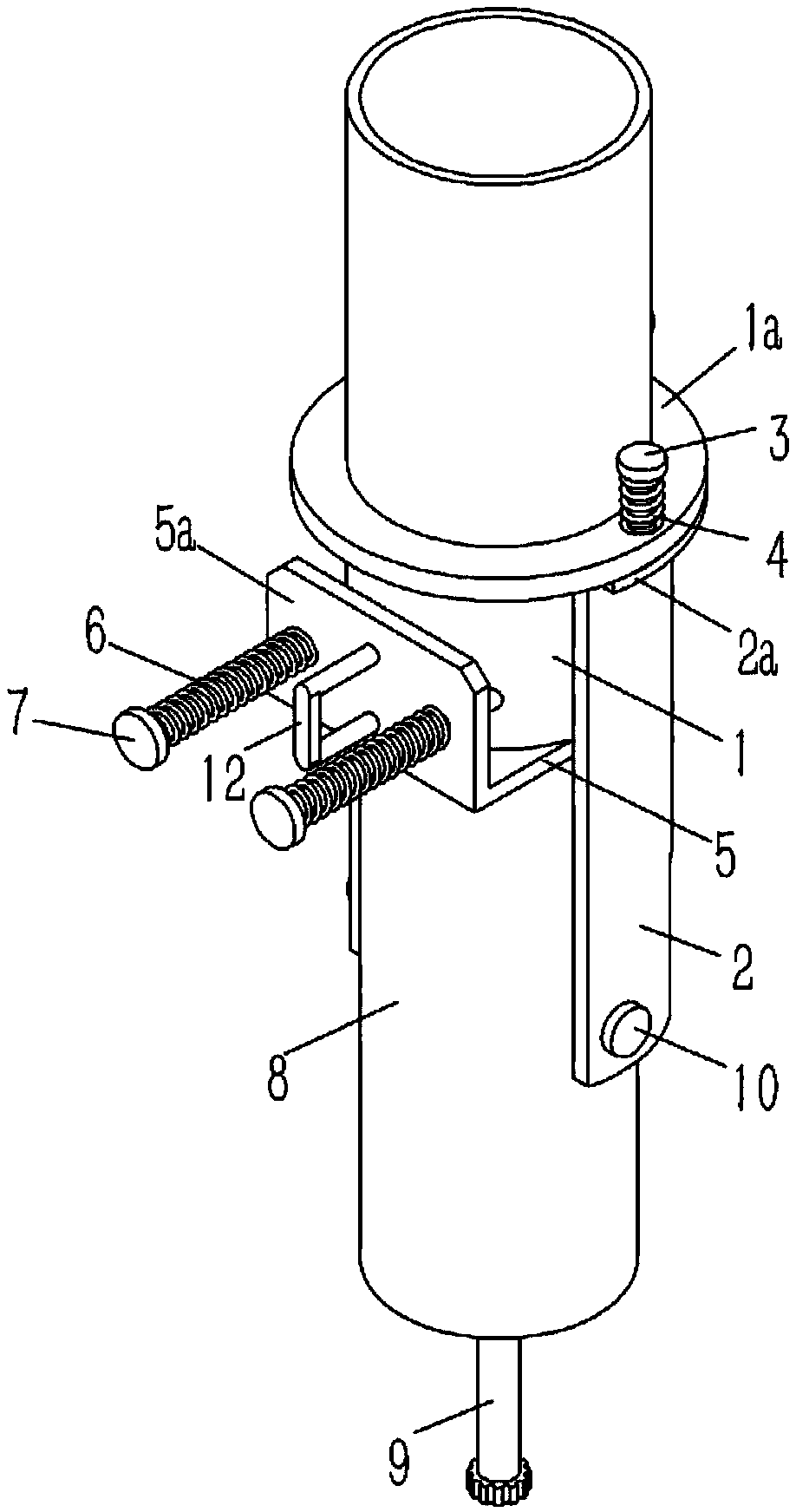

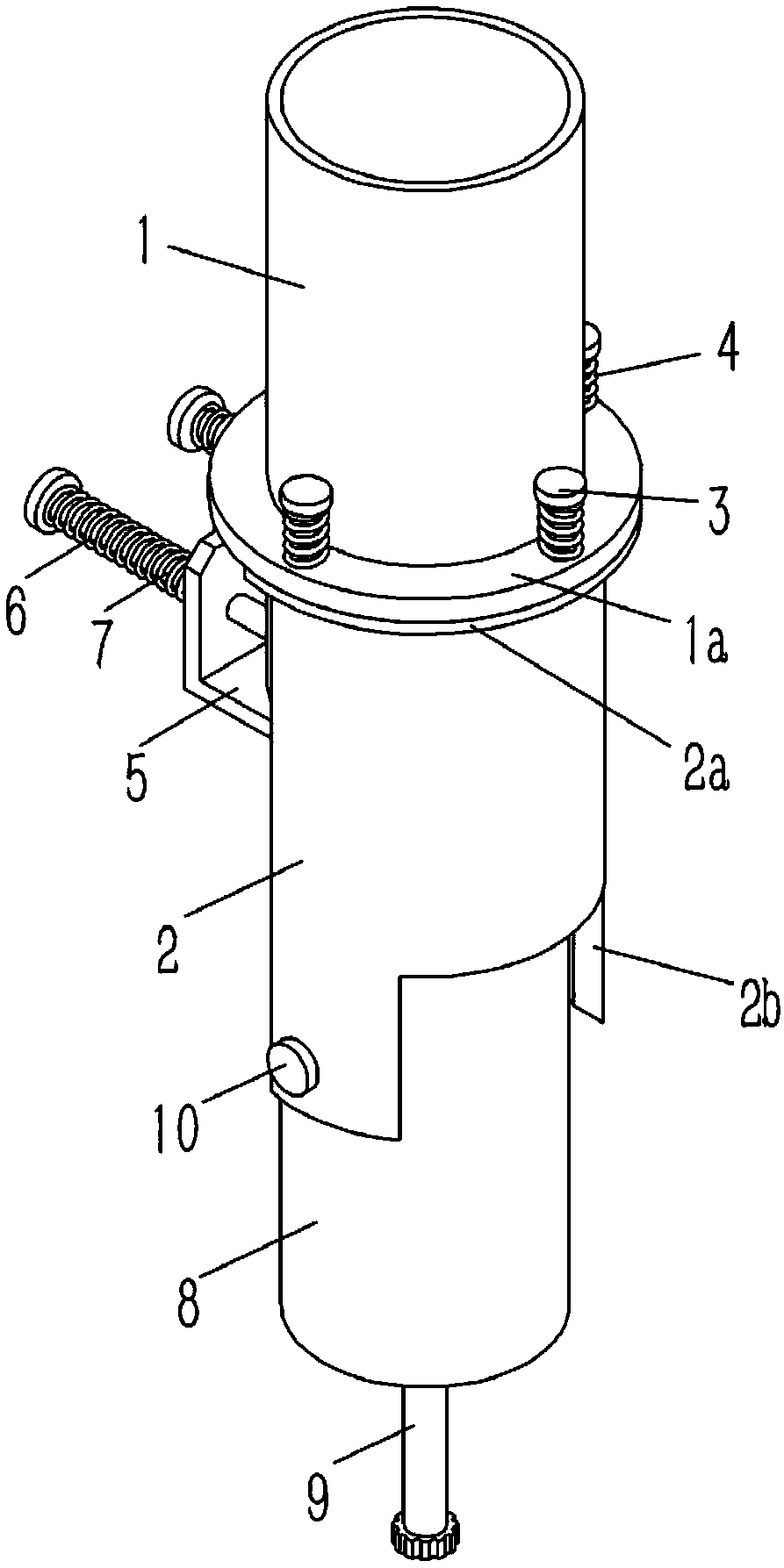

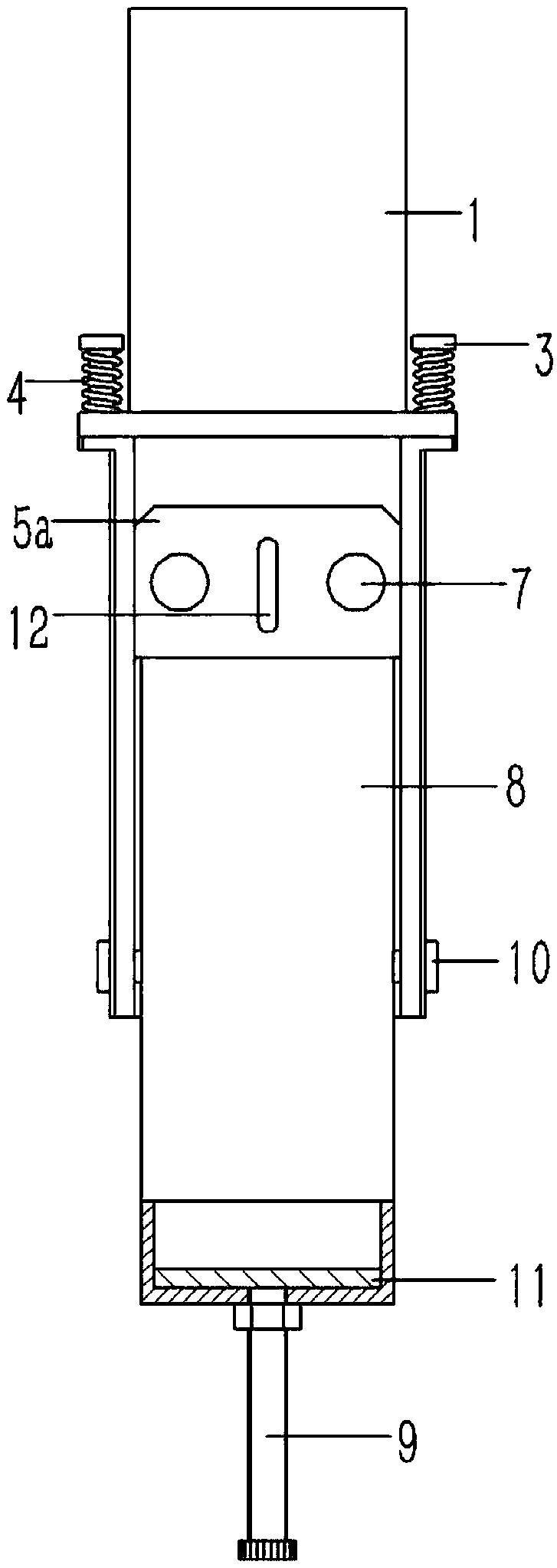

[0016] Example: see Figures 1 to 3 As shown, a quantitative feeding device applied to granular bag packaging includes a vertical discharge pipe 1, the rear side of the lower end of the discharge pipe 1 is formed with a downwardly extending arc-shaped baffle, and the discharge pipe 1 The lower end of the lower end is inserted into a positioning sleeve 2 with a circular arc line, and the rear side of the lower end of the positioning sleeve 2 is formed with a cutout 2b. The lower end of the discharge pipe 1 is against a valve plate 5, and the front end of the valve plate 5 is formed There is a vertical support plate 5a, and several T-shaped first guide rods 7 are inserted on the support plate 5a. The first guide rod 7 is inserted with a first compression spring 6, and one end of the first compression spring 6 is pressed against the The head and the other end of the first guide rod 7 lean against the support plate 5a; the lower end surface of the valve plate 5 leans against the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com