Calcium oxide-based high-temperature CO2 adsorbent and its preparation method

A CO2, calcium oxide technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of cumbersome and involved processes, and achieve the effects of improving dispersibility, inhibiting migration, and enhancing effective surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

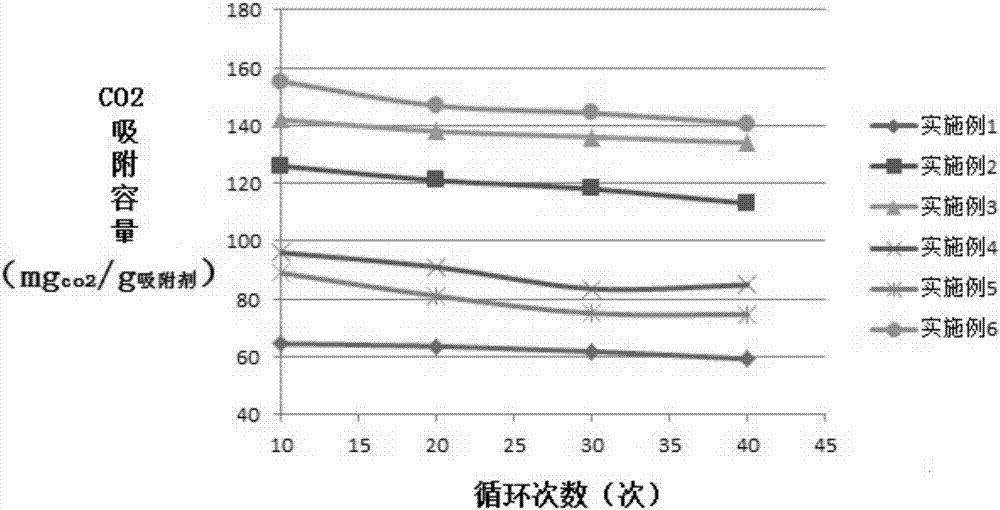

Examples

Embodiment 1

[0043] (1) Preparation of impregnation solution Ⅰ: weigh 0.772g of Ce(NO 3 ) 3 ·6H 2 O and 0.388g of La(NO 3 ) 3 ·6H 2 O, dissolved in 6.6ml of deionized water, stirred to dissolve;

[0044] (2) Weigh the γ-Al with high wear resistance that has been screened 2 o 3 Carrier 8.55g, mixed with the above-mentioned impregnating solution I, impregnated with equal volume at 60°C by ultrasonic vibration method, aged for 2 hours, dried at 110°C for 12 hours, and then calcined at 600°C for 4 hours to obtain Ce 2 o 3 / La 2 o 3 Modified γ-Al 2 o 3 carrier;

[0045] (3) Preparation of impregnation solution II: weigh 4.214g of Ca(NO 3 ) 3 4H 2 O, dissolved in 5.4ml of deionized water, stirred to dissolve;

[0046] (4) Ce obtained in step (2) 2 o 3 / La 2 o 3 Modified γ-Al 2 o 3 After the carrier is mixed with the impregnating solution II, it is impregnated in equal volume at 75°C by ultrasonic vibration method, aged for 4 hours, dried at 150°C for 12 hours, and then calc...

Embodiment 2

[0050] (1) Preparation of impregnation solution Ⅰ: weigh 3.031g of Mg(NO 3 ) 3 ·6H 2 O was dissolved in 5.5ml of deionized water and stirred to dissolve;

[0051] (2) Weigh the γ-Al with high wear resistance that has been screened 2 o 3 Carrier 7.5g, mixed with the above-mentioned impregnating solution Ⅰ, impregnated with equal volume at 60°C by ultrasonic vibration method, aged for 2 hours, dried at 110°C for 8 hours, and then calcined at 600°C for 2 hours to obtain MgO modified γ-Al 2 o 3 carrier;

[0052] (3) Preparation of impregnation solution II: Weigh 5.643 calcium acetate, dissolve in 6.8ml deionized water, and stir to dissolve;

[0053] (4) the MgO modified γ-Al obtained in step (2) 2 o 3 After the carrier is mixed with the impregnating solution II, it is impregnated with equal volume at 70°C by ultrasonic vibration method, aged for 4 hours, dried at 110°C for 12 hours, and then calcined at 800°C for 3 hours to obtain a composition of 20% CaO 5 %MgO 75% γ-Al...

Embodiment 3

[0057] (1) Preparation of impregnation solution I: Weigh 2.056g of magnesium gluconate and 0.258g of La(NO 3 ) 3 ·6H 2 O was dissolved in 6.8ml of deionized water and stirred to dissolve;

[0058] (2) Weigh the γ-Al with high wear resistance that has been screened 2 o 3 After mixing 7.7g of the carrier with the above-mentioned impregnating solution I, the ultrasonic vibration method was used to impregnate and age equal volume at 60°C for 4 hours, then dried at 100°C for 10 hours, and then calcined at 800°C for 2 hours to obtain MgO / La 2 o 3 Modified γ-Al 2 o 3 carrier;

[0059] (3) Preparation of impregnation solution II: Weigh 5.643g of calcium acetate [Ca(CH 3 COO) 2 ], dissolved in 6.8ml of deionized water, stirred to dissolve;

[0060] (4) MgO / La obtained in step (2) 2 o 3 Modified γ-Al 2 o 3 After the carrier is mixed with the impregnation solution II, it is impregnated and aged at 60°C for 6 hours by ultrasonic vibration method, dried at 200°C for 10 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com