Method for predicting quality of industrially produced coke by using 40kg test coke oven

A technology for testing coke oven and coke quality, applied in coke ovens, measuring devices, petroleum industry, etc., to achieve production benefits, reduce production risks, and maximize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0037] A kind of method utilizing 40Kg test coke oven to predict industrialized production coke quality, comprises following processing step:

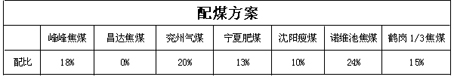

[0038] a. The coal used in the test is sampled from the coal yard. After being retrieved, gas coal, lean coal, and weakly sticky coal are mixed according to the proportion, and crushed with a hammer crusher to make it. Mix coking coal, fat coal, and 1 / 3 coking coal, and crush it with a hammer crusher to make the particle size ≤ 6mm;

[0039] b. The coal loading capacity of the iron box is 48±0.5kg (dry basis), which is loaded in six times, and tamped for 30 seconds after each loading;

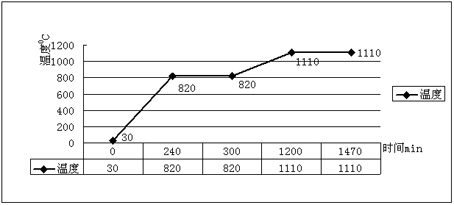

[0040] c. In the small coke oven test, coal is charged at 820°C and coke is discharged at 1110°C. The entire coking time is 20.5h. The temperature rise curve refers to the attached figure 1 ;

[0041] d. The test coke ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crushing strength | aaaaa | aaaaa |

| Abrasion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com