Tubular pile upper mould and hoisting system thereof

A technology of pipe piles and spreaders, applied in sheet pile walls, transportation and packaging, load hanging elements, etc., can solve problems such as easy decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

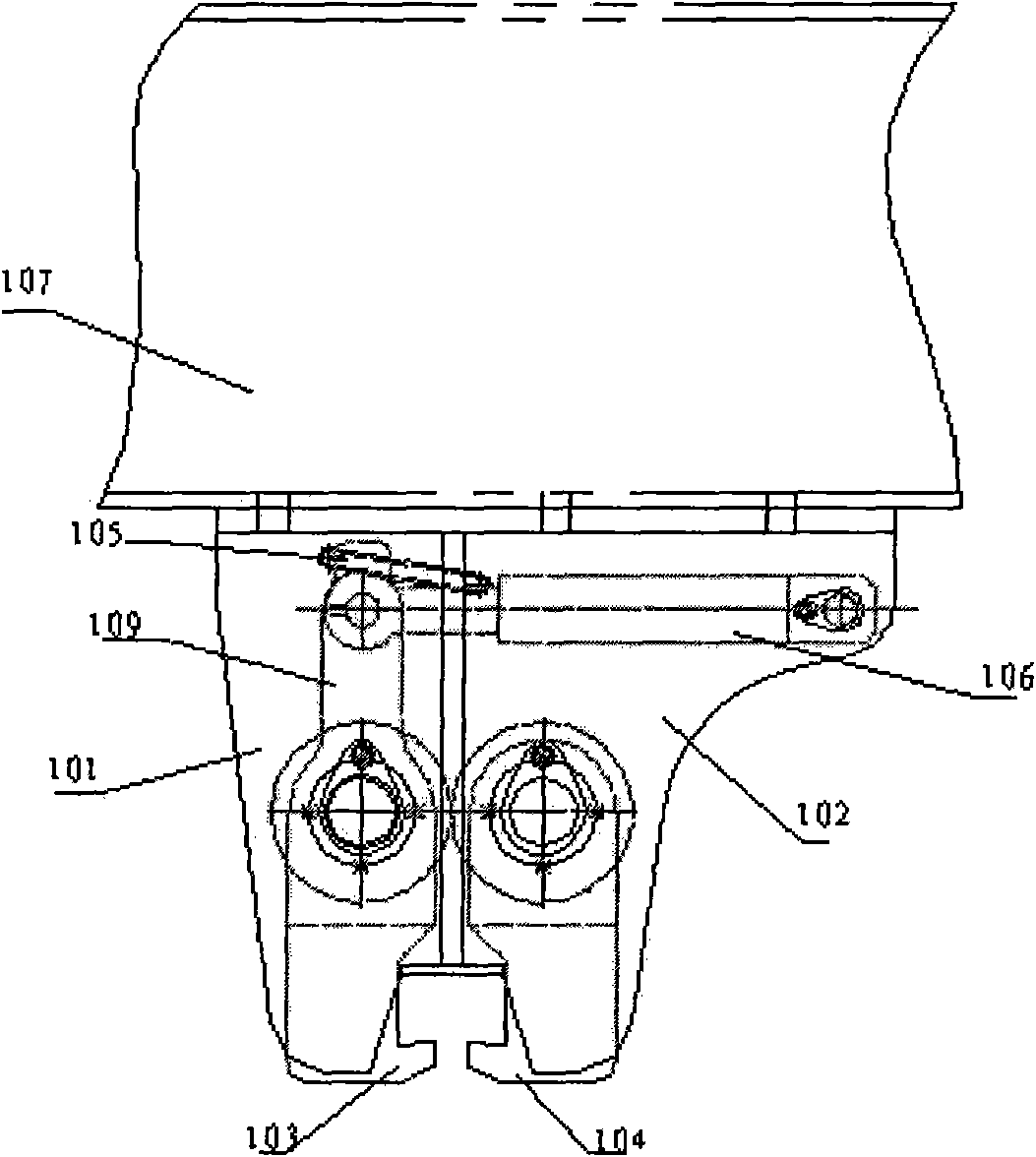

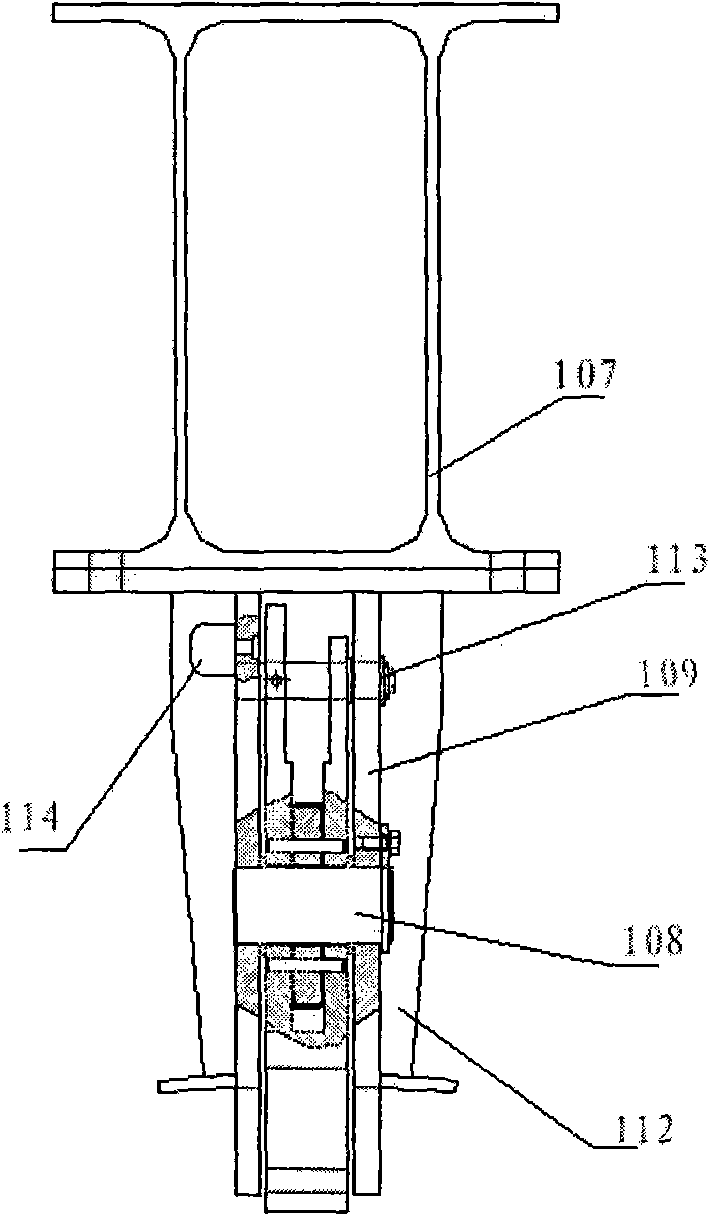

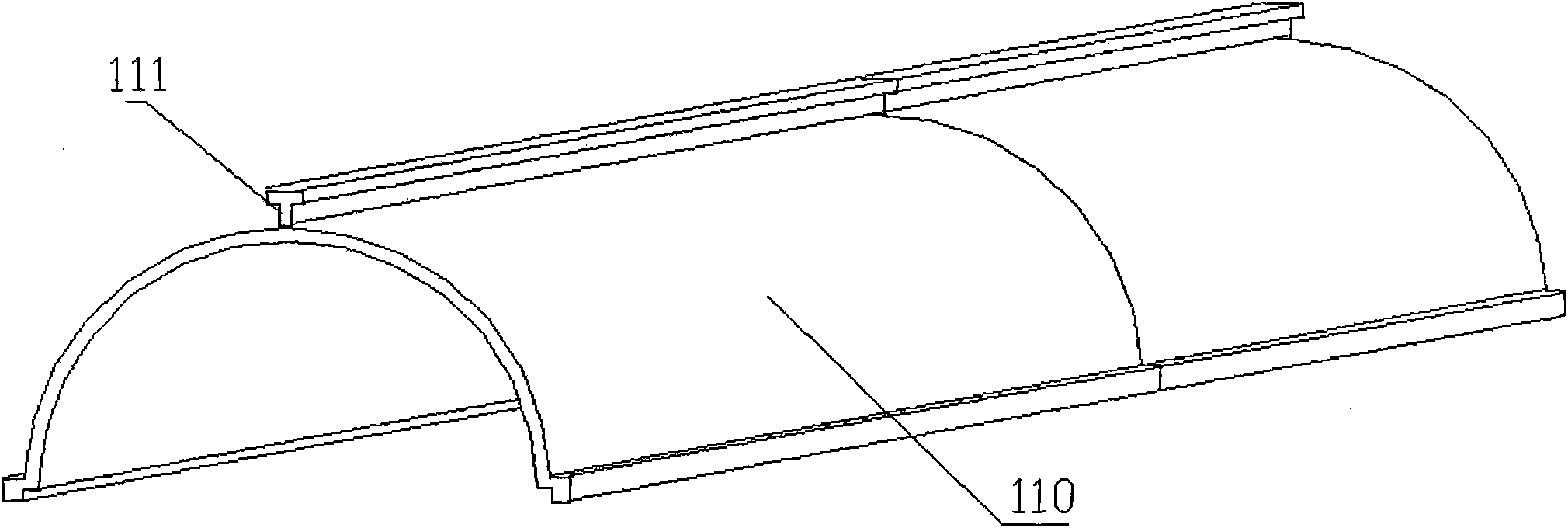

[0019] Example 1, when the staff needs to hoist the 110-tubular pile upper mold, the crane moves to the designated position, and the crane controls the 114-oil cylinder to work, so that the 105-tie rod pushes the 106-telescopic rod, because the 105-tie rod pushes the 106-telescopic rod Make 101-the left arm of the spreader and 102-the right arm of the spreader open, put down the 107-bracket in the driving control system to the height close to the height of the 111-upper mold T-frame, and then 114-oil cylinder works to pull the 105-tie rod, and the 105-tie rod pulls 106-telescopic rod, 105-pull the 106-telescopic rod to close 101-the left arm of the spreader, 102-the right arm of the spreader, and 103-the left clamp hook located at the lower end of 101-the left arm of the spreader and 102-the right arm of the spreader Engage with the 104-right clamping hook and the 111-upper mold T-frame of the 110-pipe pile upper mold, and the driving control hoisting system rises and moves to ...

Embodiment 2

[0020] Example 2. After the driving control hoisting system moves up and moves to the designated position, the driving control spreader system is lowered to 110-pipe pile upper die to place the bracket, and the driving control oil cylinder works to make 105-tie rod push 106-telescopic rod, because 105-tie rod pushes 106 -Telescopic rod makes 101-left arm of spreader, 102-right arm of spreader open, 110-pipe pile upper die 111-upper die T-frame and 01-left arm of spreader, 102-lower end of spreader right arm 103-left clamping hook and 104-right clamping hook are disengaged, and 110-pipe pile upper die is placed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com