Sulfur-smoke-free powder composition and preparation method thereof

A technology of composition and pyrotechnics, applied in the direction of explosives, etc., can solve the problems of personal casualties and property losses, low working ability, high mechanical sensitivity, etc., achieve excellent storage stability, eliminate environmental pollution, and improve environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 10 parts of barium nitrate, 55 parts of potassium perchlorate, 30 parts of guanidine nitrate, 5 parts of ethyl cellulose, and an appropriate amount of ethanol. Mix in a mixer for 30 minutes, enter a granulator, spray an appropriate amount of ethanol, granulate, dry, sieve (pass 2.24-0.80 sieve holes) and pack, and the preparation is completed. According to the GJB772A-9702601HE602.2 method to detect the above composition, the impact sensitivity (hammer weight 10 kg, drop height 25cm), the measured value is 13%, the friction sensitivity: (gauge pressure 1.25MPa, swing angle 90°), the measured value is 0%. Moisture absorption rate: 0.15%, ignition temperature: 403°C, flame sensitivity: 25.8 (the height at which the ignition rate is 50%). Potassium chlorate, lead, mercury, arsenic, sulfur are all zero.

[0018] The inner tube of the fireworks shell was tested at a launch height of 76.1 meters (75 meters for black powder), and the charge was 1 / 3 of that of traditiona...

Embodiment 2

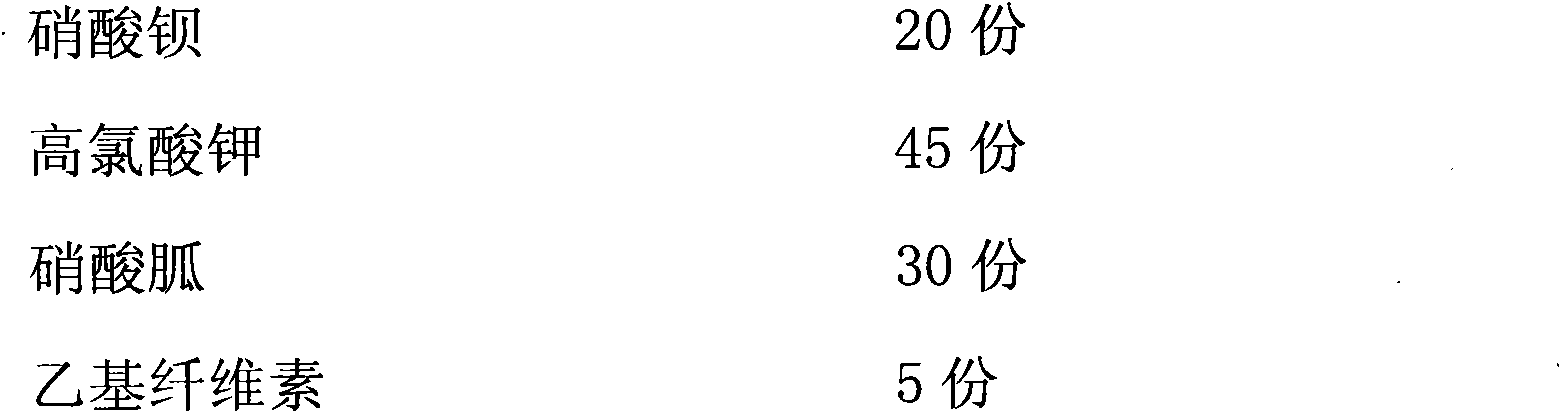

[0020] Recipe:

[0021]

[0022] Process method, process parameter and detection method are the same as embodiment 1. The moisture absorption rate rises to 1.5%, and the launch height is 70 meters. Other test indicators are the same as in Example 1.

Embodiment 3

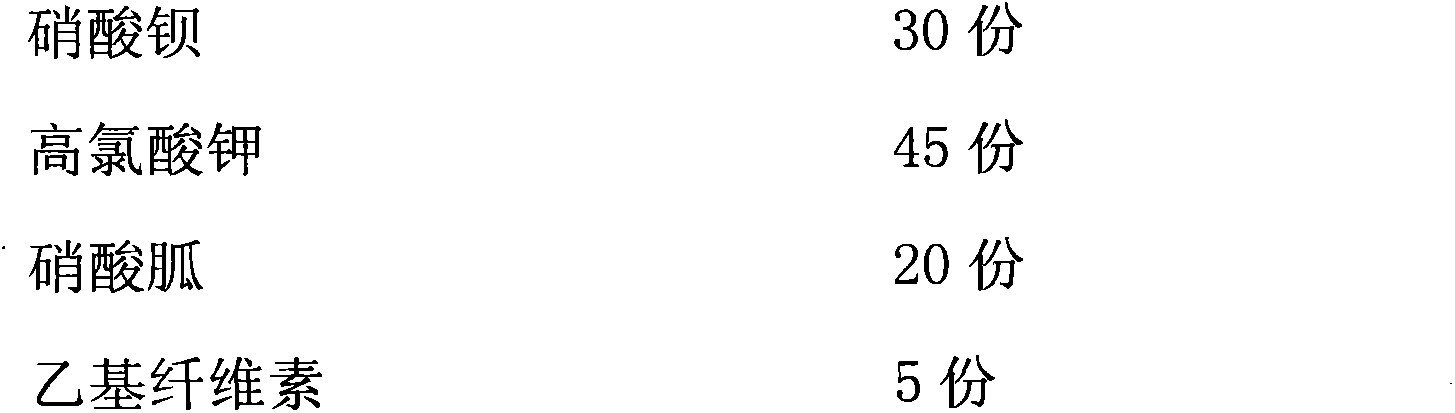

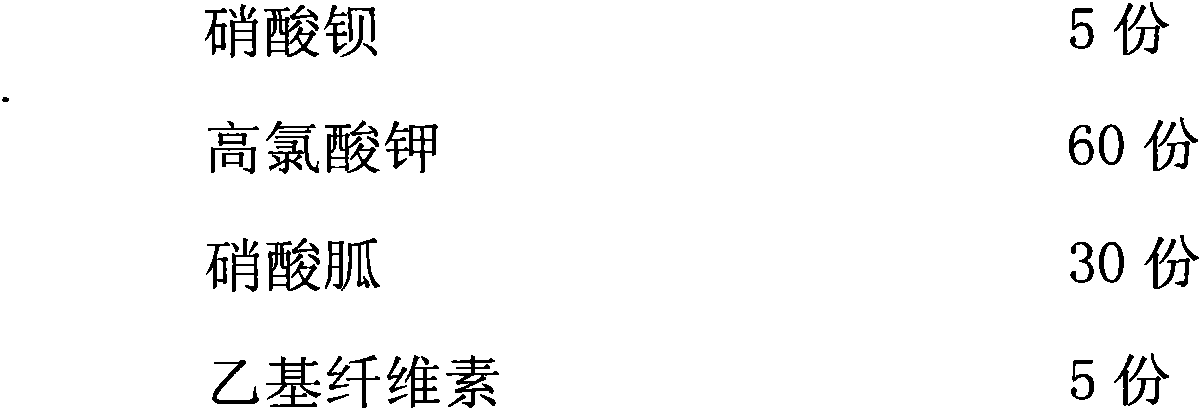

[0024] Recipe:

[0025]

[0026] The process method, process parameters and detection method are the same as implementation 1. The moisture absorption rate is 2%, the launch height is 65 meters, and other test indicators are the same as the implementation of 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com