High-performance dealcoholized organosilicon adhesive and preparation technique thereof

An organic silica gel, dealcoholized technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of prolonged surface viscosity loss, product performance decline, rubber thickening, etc. The effect of production safety factor, improved storage stability and reduced viscosity loss time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

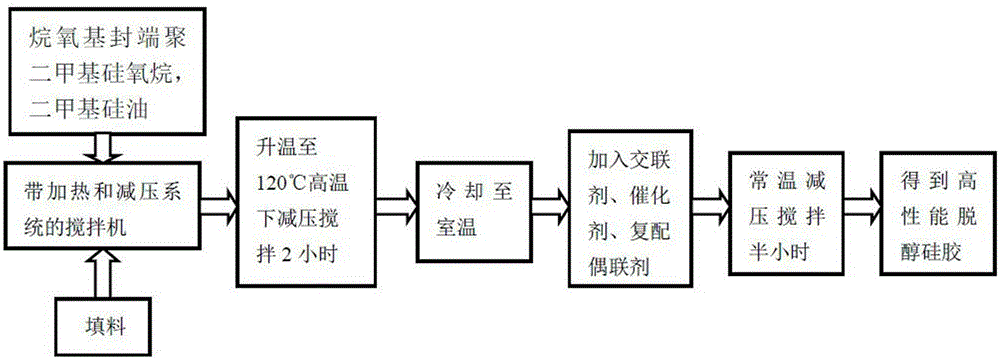

[0028] The high-performance dealcoholized organic silica gel of the present embodiment includes the following parts by weight: 100 parts of alkoxy-terminated polydimethylsiloxane, 20 parts of simethicone, 130 parts of activated nano-calcium carbonate, 2 parts Crosslinking agent methyltrimethoxysilane, 2 parts of catalyst diisopropoxybis(ethyl acetoacetate) titanium complex, 0.5 part of complex coupling agent;

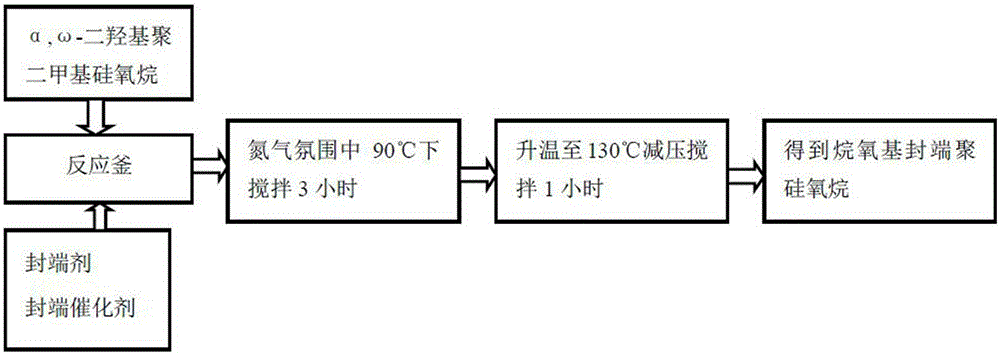

[0029] The preparation steps are: (1) Under nitrogen protection conditions, add α, ω-dihydroxypolydimethylsiloxane, tetramethoxysilane, Diethyl ketone oxime, stirred and reacted at 90°C for 3 hours, then heated up to 130°C for 1 hour under reduced pressure to obtain alkoxy-terminated polydimethylsiloxane;

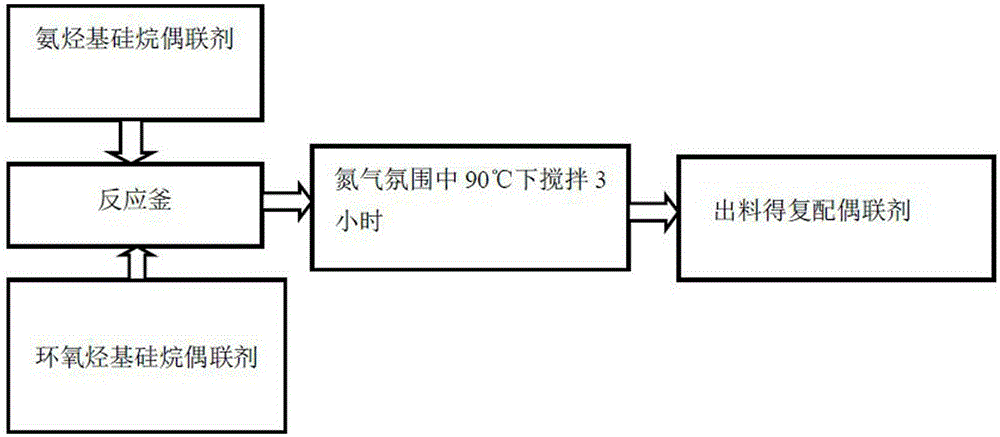

[0030] (2) Under the condition of nitrogen protection, add 3-aminopropyltriethoxysilane and 3-(2,3-epoxypropoxy)propyltrimethoxysilane to the reaction kettle at a ratio of 1:1, Stir the reaction at 90°C for 3 hours, then cool to room temperature to obtain a complex ...

Embodiment 2

[0033] The high-performance dealcoholized organic silica gel of the present embodiment includes the following parts by weight: 100 parts of alkoxy-terminated polydimethylsiloxane, 20 parts of simethicone, 90 parts of activated nano-calcium carbonate, 40 parts Heavy calcium carbonate, 3 parts of crosslinking agent vinyltrimethoxysilane, 1.5 parts of catalyst 1,3-propanedioxytitanium bis(acetylacetone) complex, 1 part of complex coupling agent;

[0034] The preparation steps are: (1) Under the condition of nitrogen protection, add 20000cps of α, ω-dihydroxy polydimethylsiloxane and tetramethoxysilane into the reaction kettle at a ratio of 100:2:5:1 , methyltrimethoxysilane, and acetone oxime, stirred and reacted at 90°C for 3 hours, then heated up to 130°C for 1 hour under reduced pressure to obtain alkoxy-terminated polydimethylsiloxane;

[0035] (2) Under the condition of nitrogen protection, add N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane and 2-(3,4-epoxy ring Hexyl) ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com