Patents

Literature

100 results about "2,2,6,6-Tetramethylpiperidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

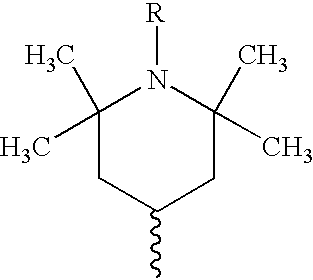

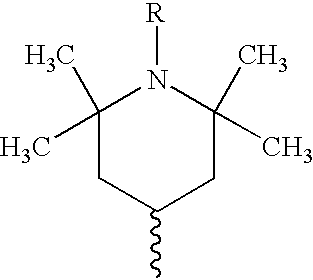

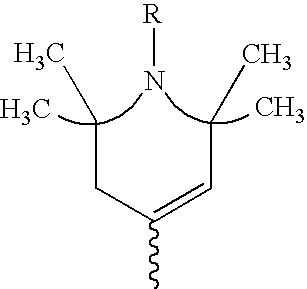

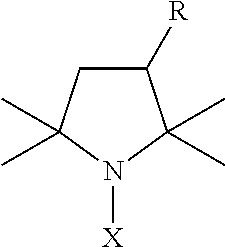

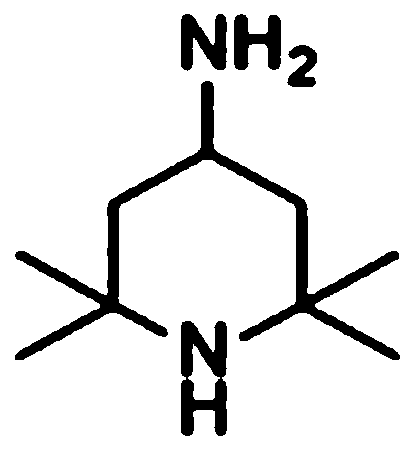

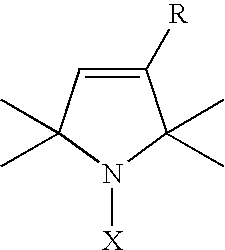

2,2,6,6-Tetramethylpiperidine or TMP or HTMP is an organic compound of the amine class. In appearance, it is a colorless liquid and has a "fishy", amine-like odor. This amine is used in chemistry as a hindered base (hindered amine). Although TMP finds limited use per se, its derivatives are a mainstay of hindered amine light stabilizers.

Energy ray-curable ink composition

ActiveUS20090197988A1Improve adhesionExcellent curabilityDuplicating/marking methodsInksHindered amine light stabilizers2,2,6,6-Tetramethylpiperidine

An object of the present invention is to provide an energy ray-curable ink composition which is excellent in curability and adhesion, and is also excellent in storage stability.The present invention relates to an energy ray-curable ink composition comprising a coloring material; a polyfunctional monomer having three or more ethylenical double bonds in one molecule as a polymerizable compound; an α-aminoalkylphenone-based compound and a thioxanthone-based compound as photopolymerization initiators; and a hindered amine-based compound having a 2,2,6,6-tetramethylpiperidinyl group as an antigelling agent.

Owner:MAXELL HLDG LTD

Rubber composition for a colored tire

InactiveUS6344506B2Assess the hardness of the compositionsReduce clearanceOrganic chemistrySpecial tyresElastomerPolymer science

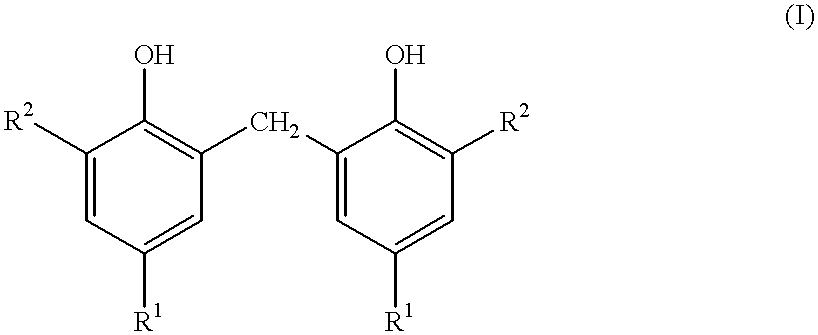

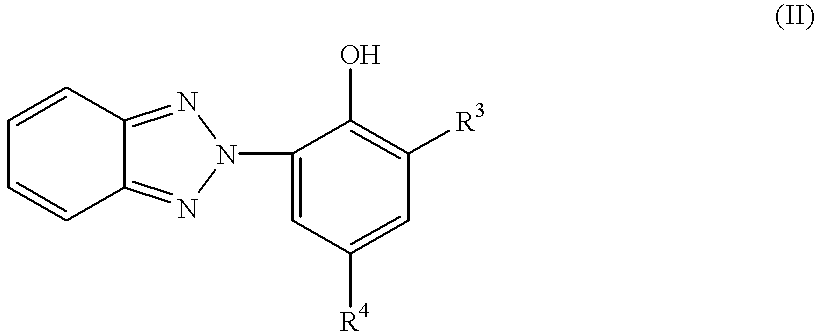

The invention concerns a white, light-colored tire rubber composition, devoid of carbon black, comprising at least a diene elastomer, a reinforcing white or colored filler, and an anti-photo-oxidizing system, wherein said protective system comprises (A) a 2,2'-methylene-bis-[4-alkyl (C1-C10)-6-alkyl(C1-C12)phenol]; (B) a dialkylthiodipropionate, the alkyl radicals thereof, which may be identical or different, are (C1-C20), radicals; (C) a 2-(2-hydroxyphenyl) benzotriazole; and (D) a "HALS" amine derived from 2,2,6,6-tetramethylpiperidine.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Oxidation nanocellulose adsorbing material and preparation method thereof

ActiveCN105498733AMicroscale reductionImprove accessibilityOther chemical processesSorbentCatalytic effect

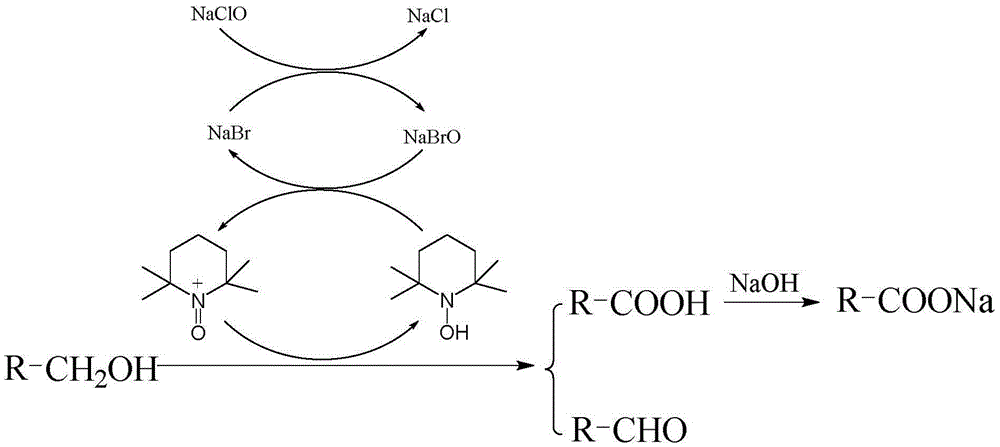

The invention provides a preparation method of an oxidation nanocellulose adsorbing material. The preparation method comprises the following steps of conducting pretreatment and then cleaning cellulose; and under the catalytic action of 2, 2, 6, 6-tetramethyl piperidine-nitrogen-oxide and sodium bromide, conducting an oxidation reaction on obtain cellulose under the action of an oxidizing agent, so that oxidation nanocellulose is obtained, wherein sodium hypochlorite serves as the oxidizing agent; mixing the nanocellulose with an organic solution containing amino high molecules, then conducting centrifugation, then mixing the mixture with a cross-linking agent, and conducting a reaction, so that the oxidation nanocellulose adsorbing material is obtained. By means of the preparation method, the specific surface area of the cellulose is increased, the contactable performance of heavy metal pollutants and adsorbent is improved, the surface of the material can have a large number of adsorption functional groups, and heavy metal ions can be aggregated to the surface of the adsorbent from a sewage system through the complexation effect and the electrostatic effect. The invention further provides the oxidation nanocellulose adsorbing material.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Power cable

InactiveUS6858296B1Excellent peelabilitySatisfactory level of thermal stabilityPlastic/resin/waxes insulatorsSynthetic resin layered productsInsulation layerElectrical conductor

This invention is directed to a cable for electrical conductors which has insulation layer which includes a 2,2,6,6-tetramethylpiperidine and a strippable insulation shield layer which includes a copolymer of acrylonitrile and butadiene.

Owner:UNION CARBIDE CORP

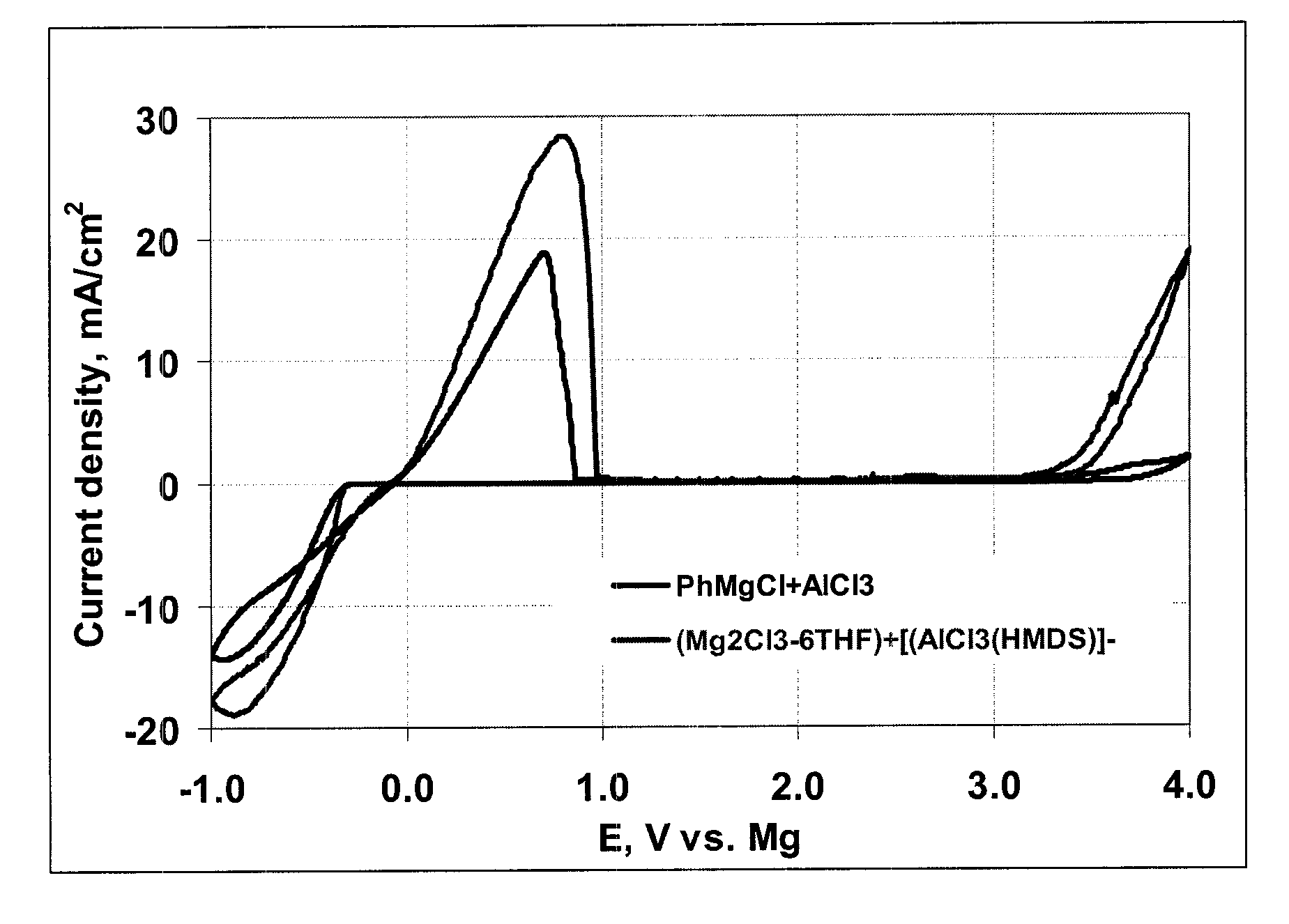

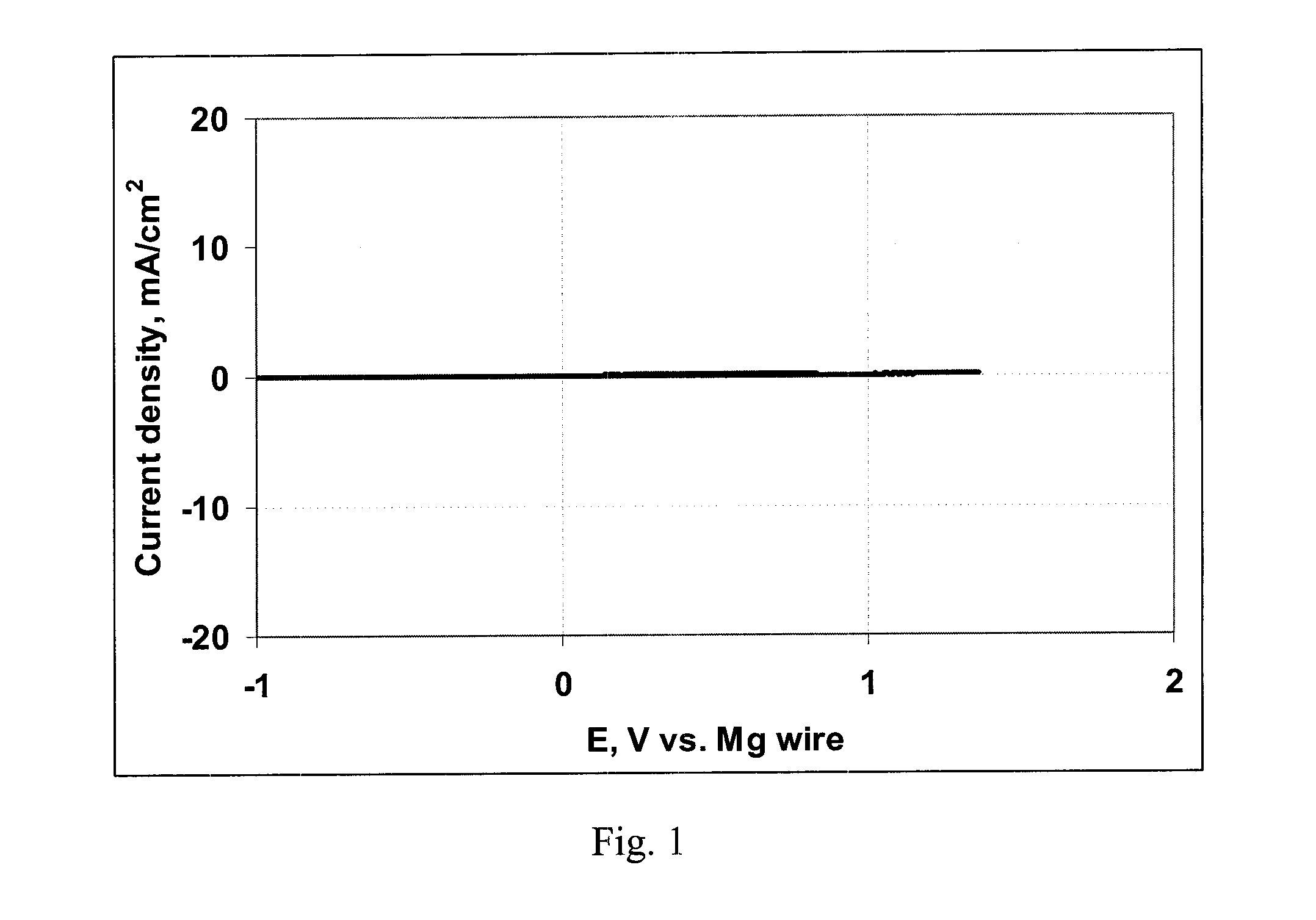

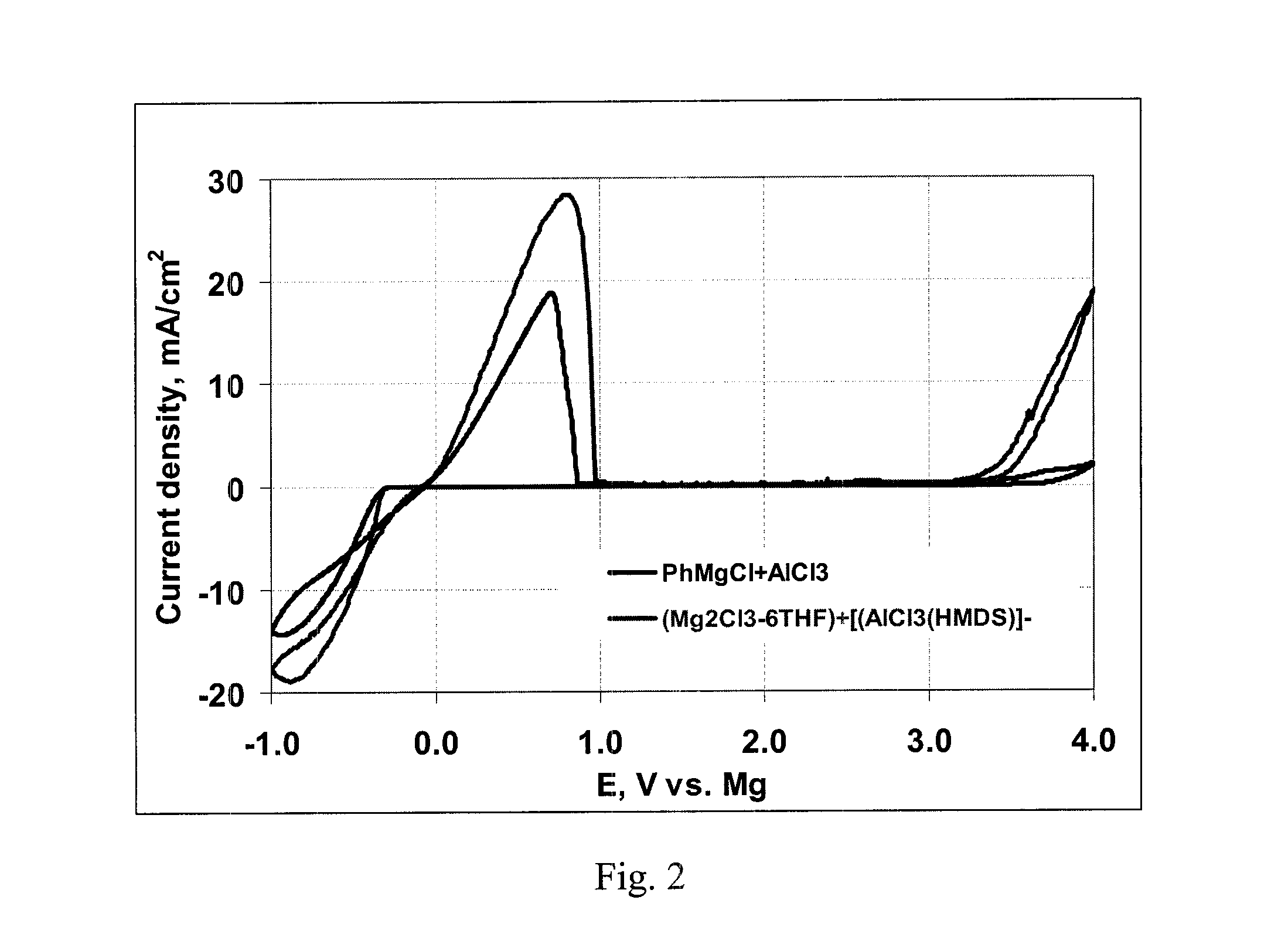

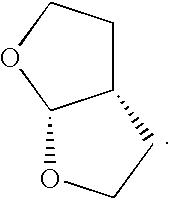

Electrochemical device with a magnesium anode and a stable, safe electrolyte compatible with sulfur

InactiveUS20120107698A1Ease of costManufacturing EaseAlkaline accumulatorsOrganic electrolyte cellsLithium chlorideSulfur

An electrochemical device, having an anode containing magnesium; a cathode stable to a voltage of at least 3.2 V relative to a magnesium reference; and an electrolyte containing a solvent and a LiCl complex of a magnesium halide salt of a sterically hindered secondary amine is provided. In a preferred embodiment the electrolyte contains tetrahydrofuran and 2,2,6,6-tetramethylpiperidinyl-magnesium chloride-lithium chloride complex.

Owner:TOYOTA MOTOR CO LTD

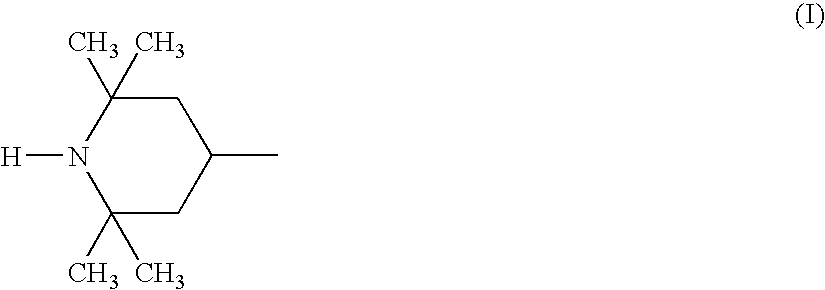

Co2 absorption from gas mixtures using an aqueous solution of 4-amino-2,2,6,6-tetramethylpiperidine

InactiveUS20120017762A1Easy loadingLess corrosiveGas treatmentOther chemical processesSulfolaneHydrogen

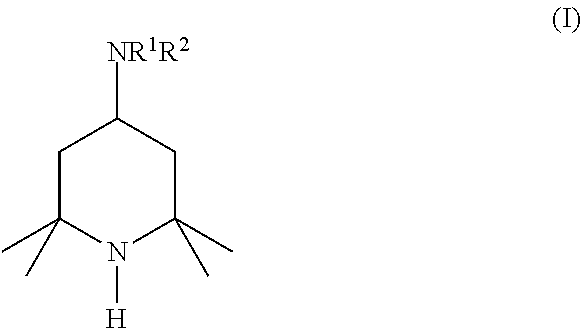

CO2 is absorbed from a gas mixture by bringing the gas mixture into contact with an absorbent that comprises water and at least one amine of the formula (I), wherein R1 and R2, independently of each other, are hydrogen or an alkyl group. According to the invention, absorption media comprise sulfolane or an ionic liquid in addition to water and an amine of the formula (I). A device according to the invention for removing CO2 from a gas mixture comprises an absorption unit, a desorption unit, and an absorption medium according to the invention that is conducted in the circuit.

Owner:EVONIK DEGUSSA GMBH

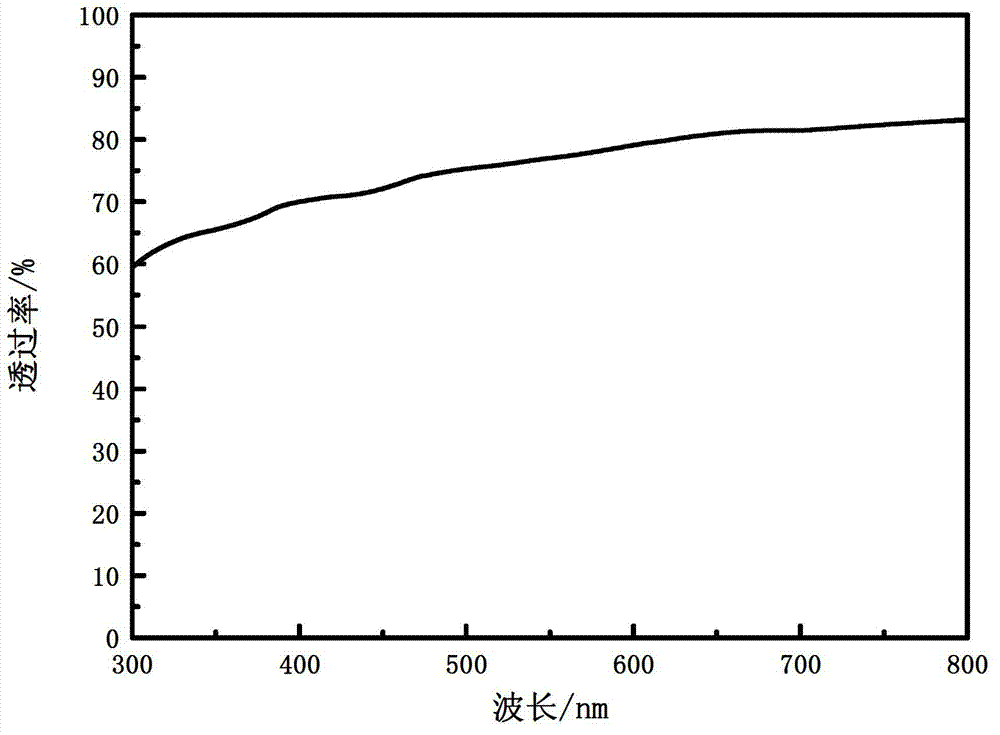

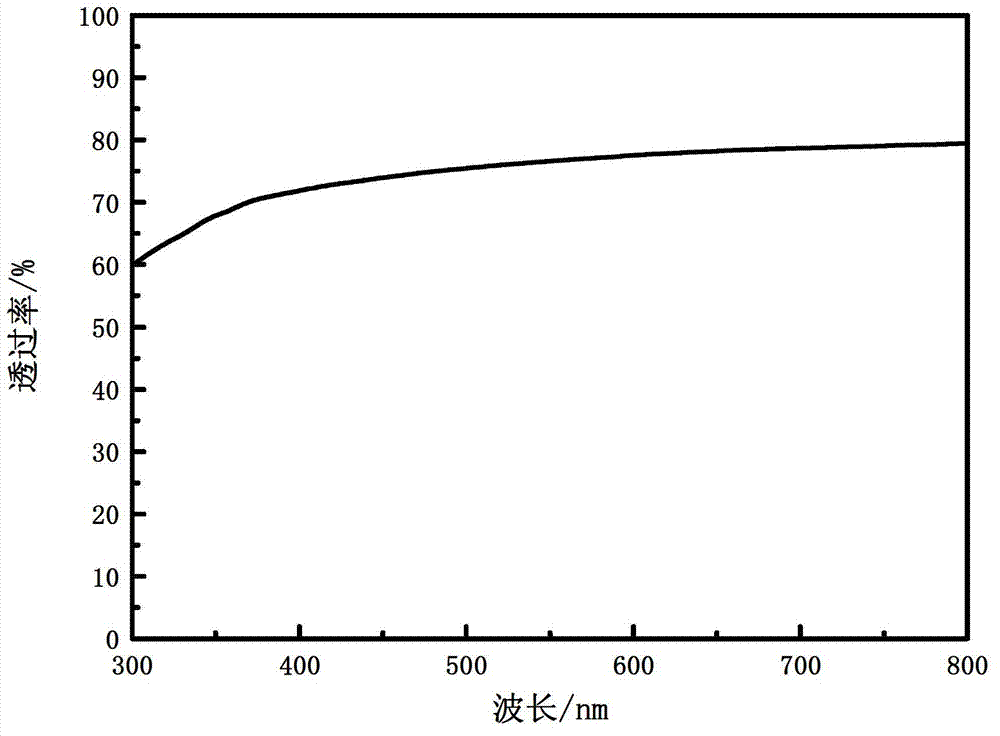

Preparation method of cellulose nanofiber-based flexible transparent conductive membrane

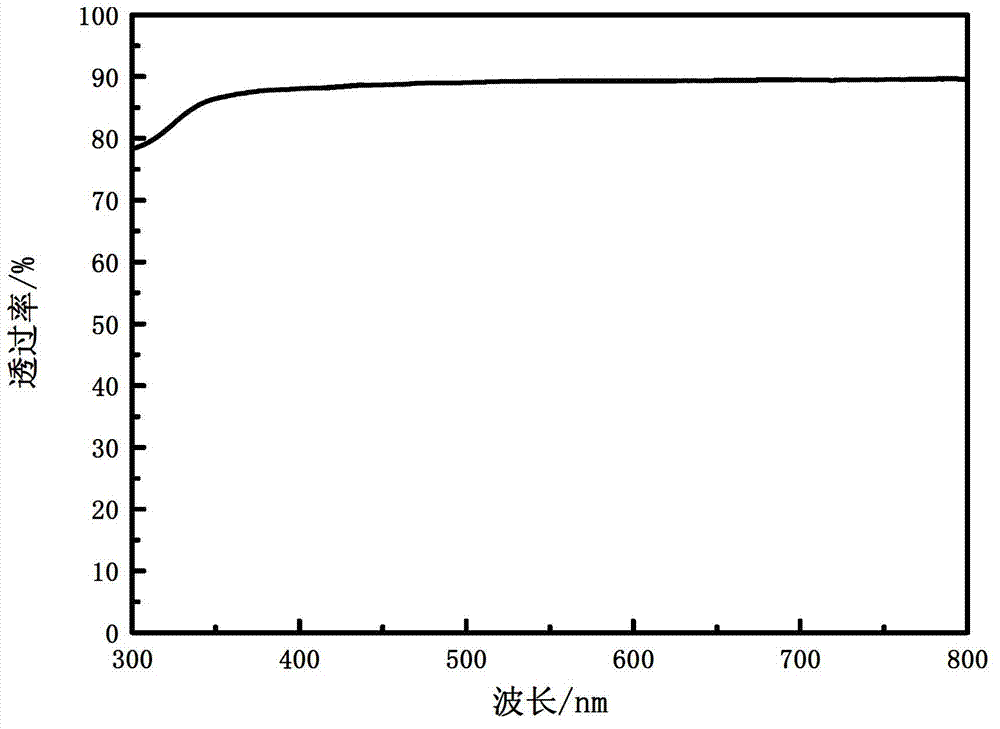

InactiveCN102737786APhotoelectric performance impactImprove photoelectric performanceConductive layers on insulating-supportsCable/conductor manufactureCelluloseFiber

The invention relates to a preparation method of a cellulose nanofiber-based flexible transparent conductive membrane. Cellulose nanofibers (CNFs) solution is prepared by utilizing TEMPO catalytic oxidation method, a colorless transparent CNFs membrane is obtained after the solvent is completely evaporated, then a layer-by-layer self-assembling technology is adopted to alternately deposit metal ions (or polymer positive ions) and graphene oxide (GO) on the CNFs membrane to prepare a CNFs / RGO film, and finally hydroiodic (HI) acid is used for reducing the GO to reduced graphene oxide (RGO) to obtain the CNFs / RGO flexible transparent conductive membrane. The density of the CNFs membrane is 1.6g*cm<-3>, the light transmission rate at 550nm is 89.2 percent, and the heat expansion coefficient is 8.5ppm*k-1; and the range of the light transmission rate at the position of 550nm is 50.4 to 77.1 percent, the range of a square resistor is 0.76 to 13.79 kilo ohm / sq, and the range of the heat expansion coefficient is 5.03 to 8.24ppm*K-1.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

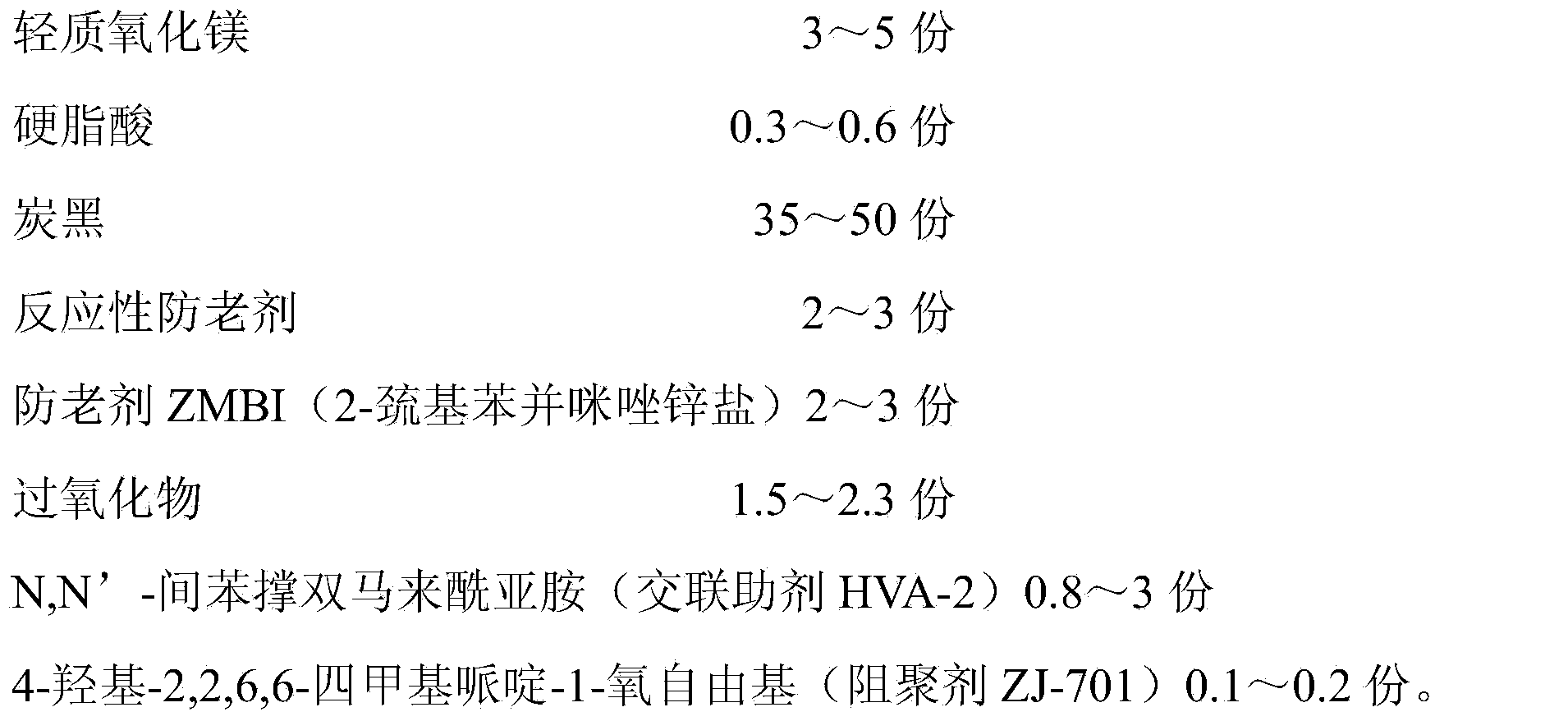

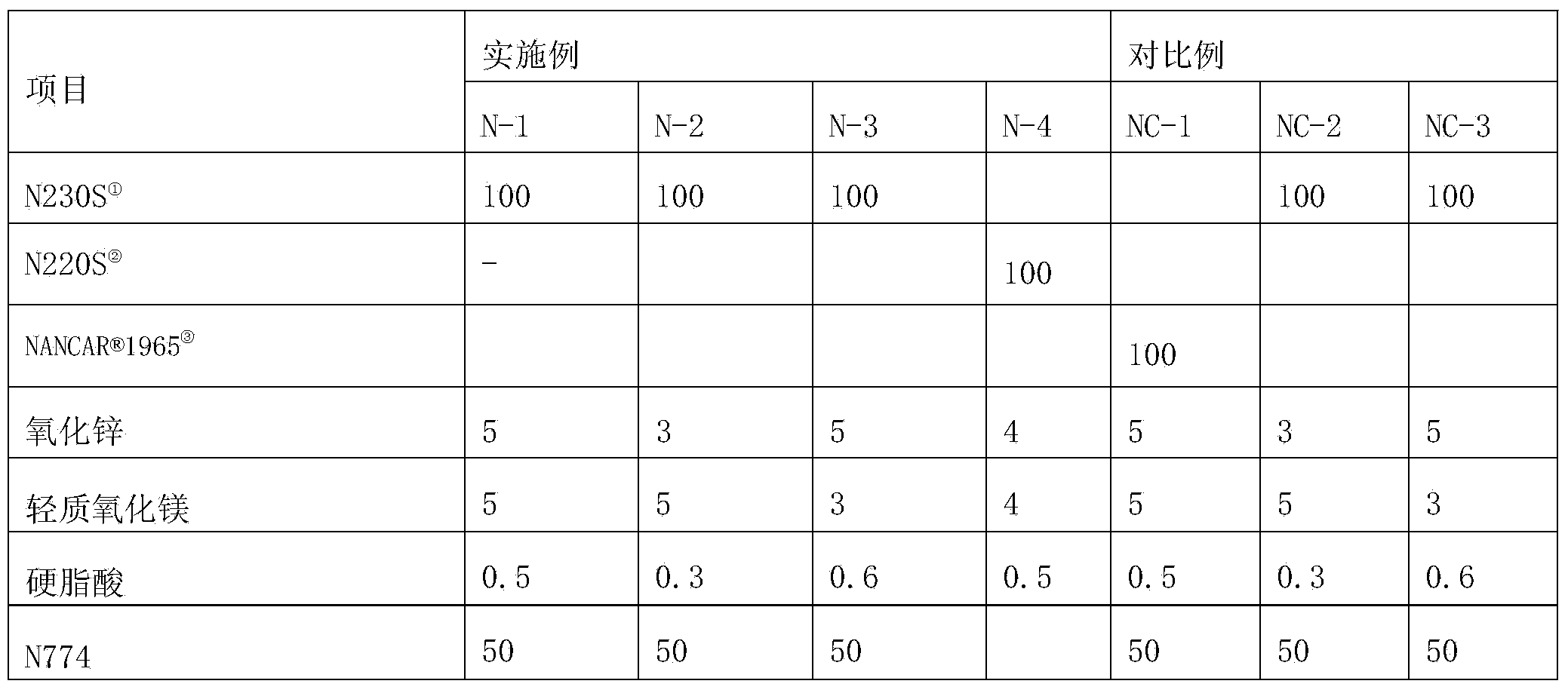

Heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as preparation method and application thereof

The invention belongs to the technical field of rubber seal and discloses a heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as a preparation method and application thereof. The butadiene-acrylonitrile rubber material comprises the following components in parts by mass: 100 parts of butadiene-acrylonitrile rubber,3-5 parts of zinc oxide, 3-5 parts of light magnesium oxide, 0.3-0.6 part of stearic acid, 35-50 parts of carbon black, 2-3 parts of a reactive antioxidant, 2-3 parts of 2-mercapto benzimidazole zinc salt, 1.5-2.3 parts of peroxide, 0.8-3 parts of N,N'-m-phenylene dimaleimide and 0.1-0.2 part of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxygen radical. After the rubber material is subjected to hot-air ageing at 120 DEG C for 70 hours, the permanent compression deformation rate (a type B sample) is not more than 18% and the break elongation rate and the retention rate are more than 90%. The rubber material is especially suitable for manufacturing oil-resistant static seal parts capable of being used at 100-120 DEG C for a long term, and can endow seal products with excellent durability.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Radiation curable ink composition

A radiation curable ink composition includes a first 2,2,6,6-tetramethylpiperidinyl compound. The first 2,2,6,6-tetramethylpiperidinyl compound is present in the radiation curable ink composition at a concentration above 0.5 wt %. A hindered amine group of the first 2,2,6,6-tetramethyl-piperidinyl compound is substituted with only carbon or hydrogen and is a solid at 20 degrees centigrade and does not include carbon to carbon double bonds.

Owner:3M INNOVATIVE PROPERTIES CO

Nitroxides for use in treating or preventing neoplastic disease

Pharmaceutical compositions are provided that are useful in treating or preventing neoplastic disease, such as cancer. The compositions comprise a pharmaceutically acceptable carrier, and an effective therapeutic or prophylactic amount of a nitroxide antioxidant that alters the expression of one or more genes related to the cancer. Methods are also provided for the use of the pharmaceutical compositions in the treatment or prevention of cancer. In a preferred embodiment, the nitroxide antioxidant is Tempol (4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl), and the cancer is esophageal cancer, hepatocellular carcinoma, colon cancer, prostate cancer, lung cancer, gastric carcinoma, renal cell carcinoma, bone cancer, breast cancer, cervical cancer, brain cancer, or a cancer associated with the tumor suppressor gene p53.

Owner:MATRIX BIOMED INC

Co2 absorption from gas mixtures using an aqueous solution of 4-amino-2,2,6,6-tetramethylpiperidine

Owner:EVONIK DEGUSSA GMBH

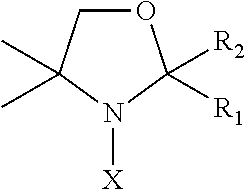

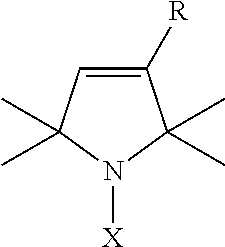

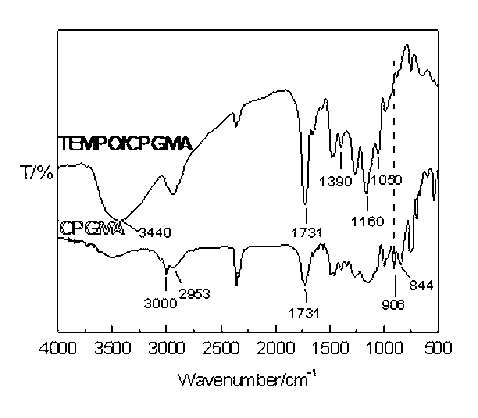

Epoxy polymer microsphere immobilized tetramethyl-piperidyl-nitroxide free radical catalyst, as well as preparation method and application method thereof

InactiveCN103285922ARealize immobilizationImprove thermal stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyGlycidyl methacrylate

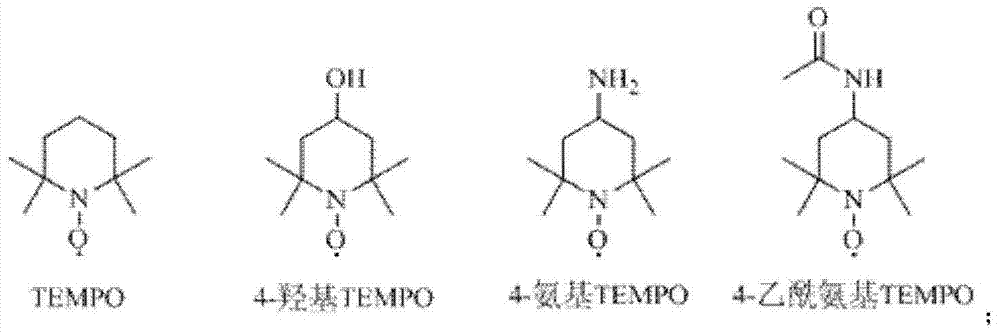

The invention belongs to the field of nitroxide free radical catalysts, aims at solving the problem that the existing homogeneous catalyst TEMPO (tetramethyl-piperidyl-nitroxide free radical) is difficult to separate and recover after reaction and can not be reused to seriously restrict development of a catalytic system, and provides an epoxy polymer microsphere immobilized (tetramethyl-piperidyl-nitroxide free radical) TEMPO catalyst, as well as a preparation method and an application method thereof. According to the preparation method, 4-OH-TEMPO (4-hydroxy-2,3,6,6-tetramethyl-piperidyl-nitroxide free radical) is bonded on a (crosslinked poly glycidyl methacrylate microsphere) CPGMA to prepare the solid catalyst TEMPO / CPGMA shown in the general formula I immobilized by TEMPO. According to the preparation method, the TEMPO is subjected to chemical bonding on a solid carrier, immobilization of TEMPO is realized, homogeneous catalysis oxidation is changed to heterogeneous catalysis oxidation, and therefore, the heat stability of the catalyst is improved, separation of the catalyst from a reaction medium is convenient, the catalyst is reused, and high activity can be generated.

Owner:ZHONGBEI UNIV

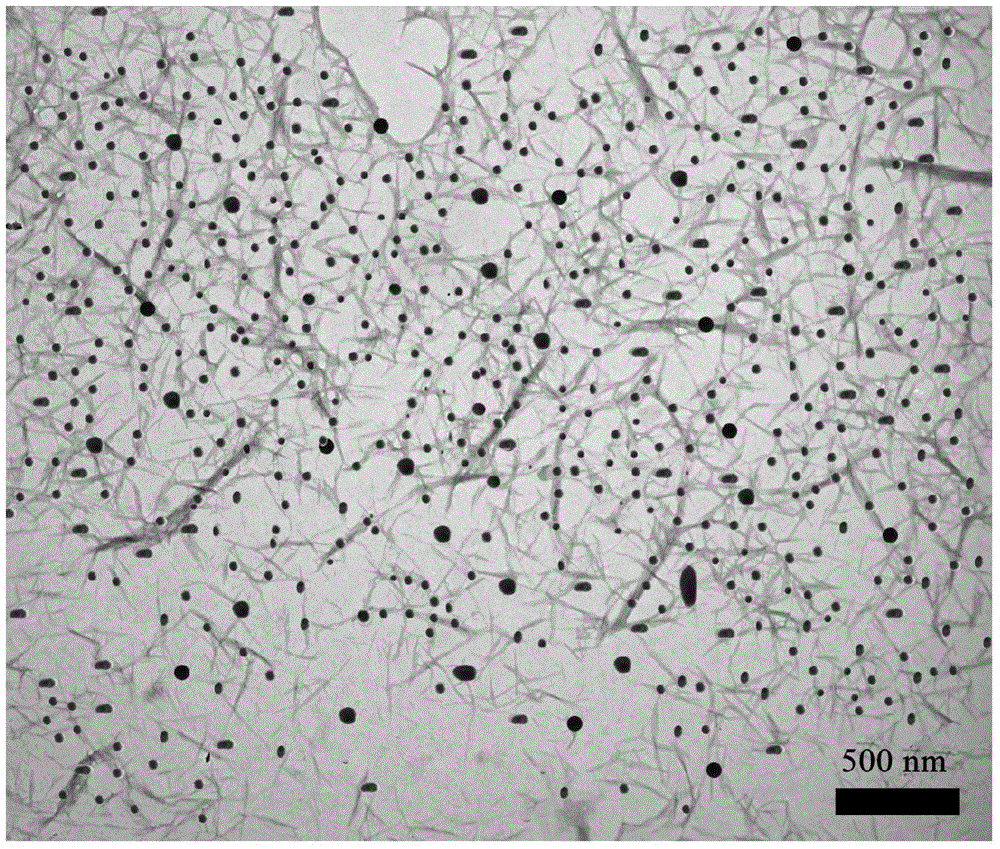

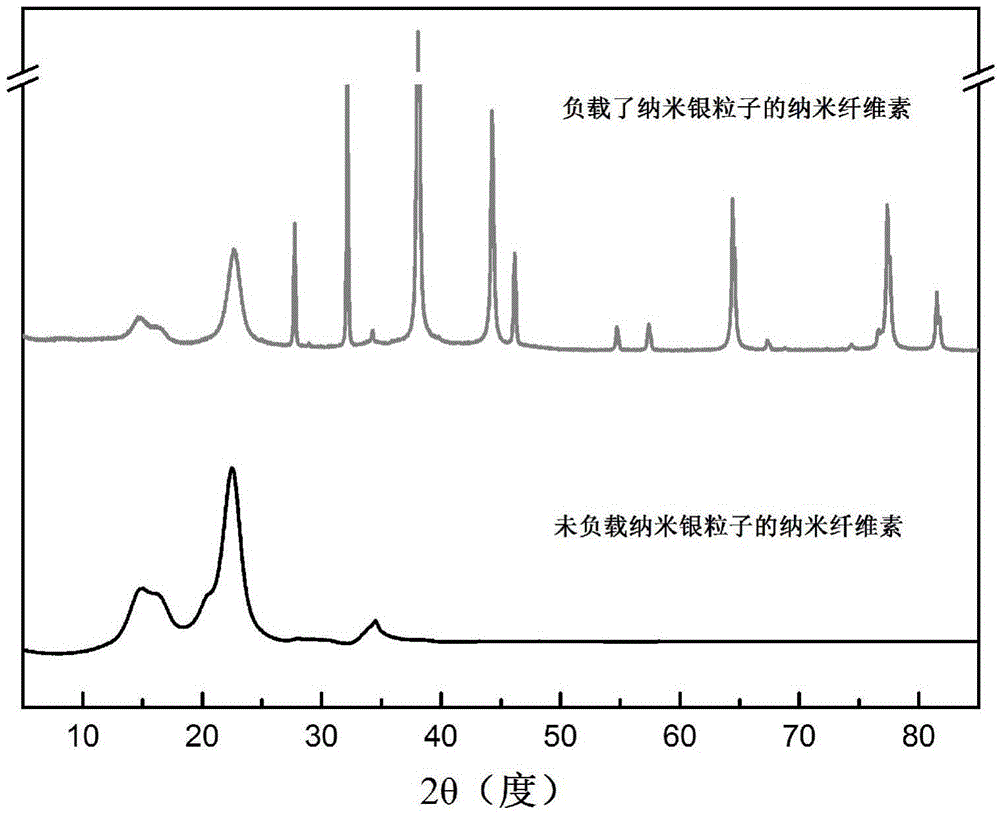

Preparation method of nano-silver particle supported nanocellulose antibacterial film

ActiveCN105646923AAddress uneven distributionSolve problems that are prone to reunionWater bathsWound dressing

The invention provides a preparation method of a nano-silver particle supported nanocellulose antibacterial film. In the method, a cellulose raw material is treated with 2,2,6,6-tetramethylpiperidine-1-oxygen radical, sodium bromide and sodium hypochlorite and then has a reaction under the condition of a water bath, and nano-silver particle supported nanocellulose is prepared. By means of the method, the problems of non-uniform dispersion and high probability of agglomeration of silver particles in nanocellulose are solved, no special instrument and toxic reagents are used, and the nano-silver particle supported nanocellulose antibacterial film has wide application prospect in antibacterial wound dressing, food storage and fresh keeping and other industrial fields.

Owner:山东银鹰化纤有限公司

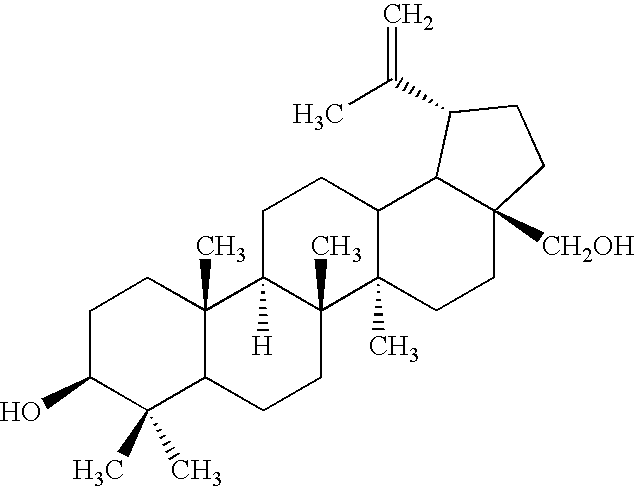

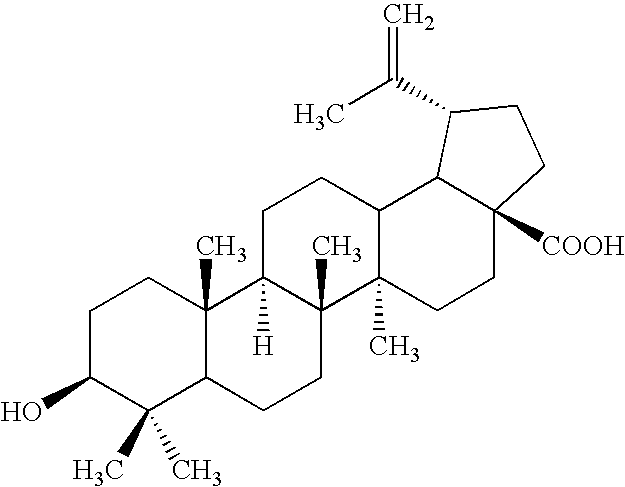

Selective oxidation of triterpenes employing tempo

The present invention provides a process of preparing betulin-28-aldehyde from betulin. The process includes contacting betulin with a compound of formula (I), e.g., TEMPO (2,2,6,6-tetramethylpiperidine 1-oxyl) for a period of time effective to provide betulin-28-aldehyde. The present invention also provides a process of preparing betulinic acid. The process includes contacting betulin with a composition that includes: sodium hypochlorite (NaOCl); sodium chlorite (NaClO2), potassium chlorite (KClO2), or a combination thereof; and a compound of formula (I), e.g., TEMPO (2,2,6,6-tetramethylpiperidine 1-oxyl); for a period of time effective to provide betulinic acid.

Owner:RGT UNIV OF MINNESOTA

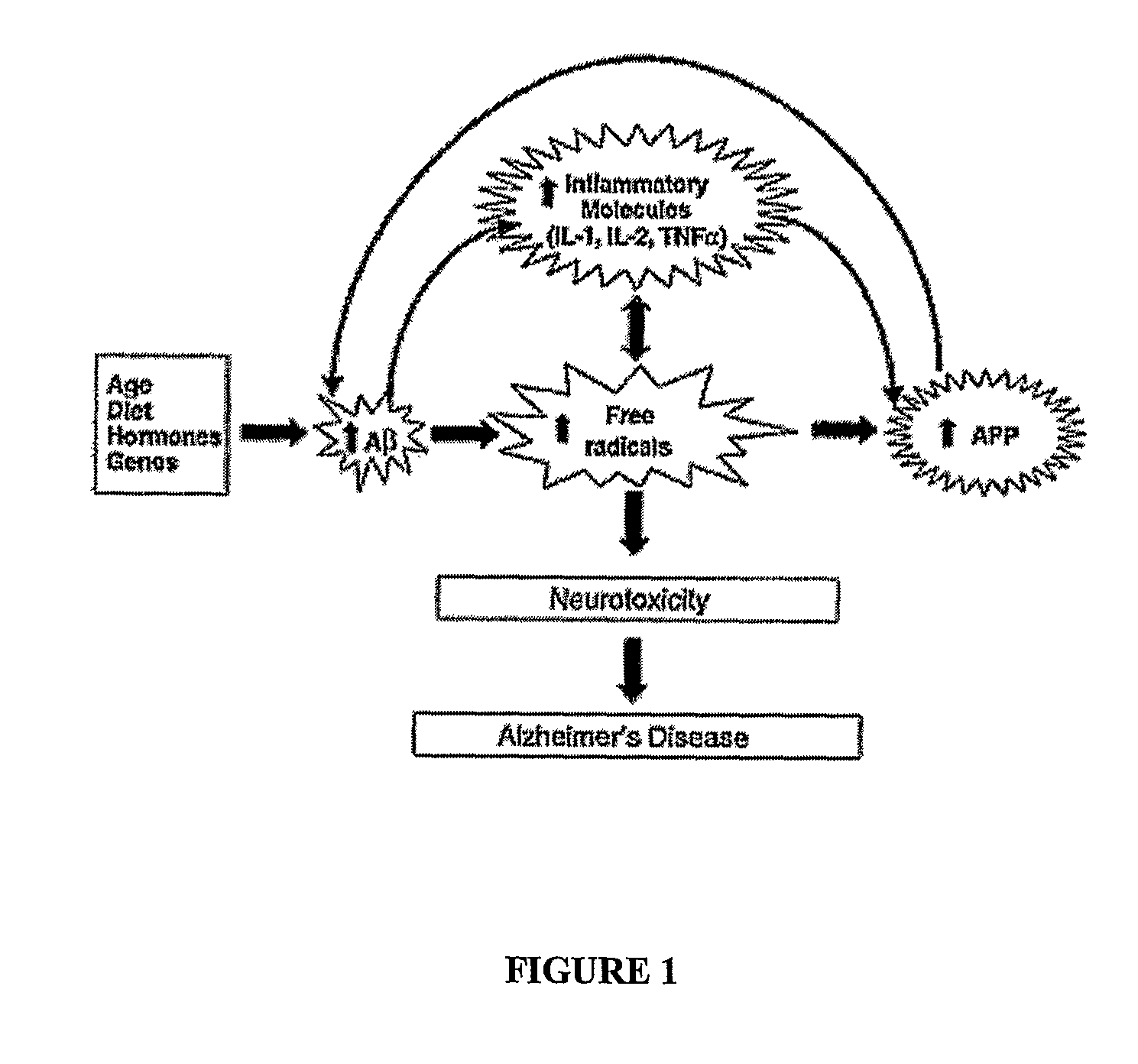

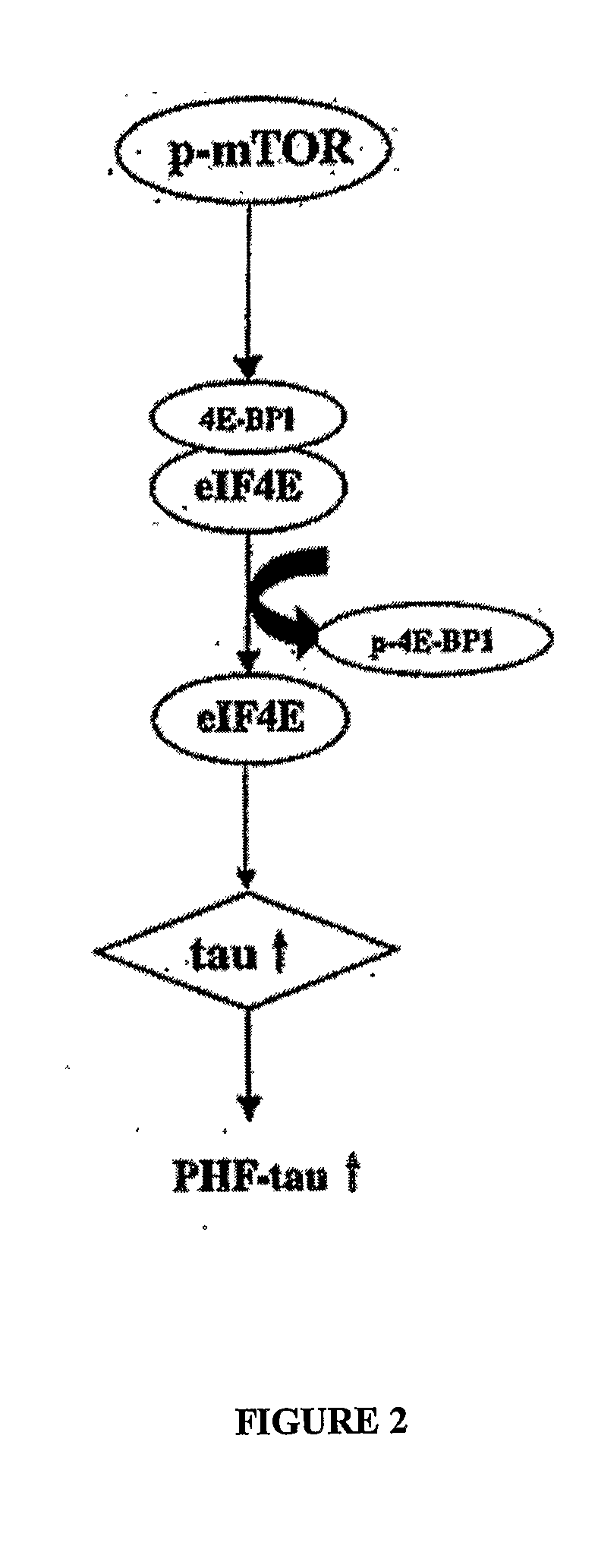

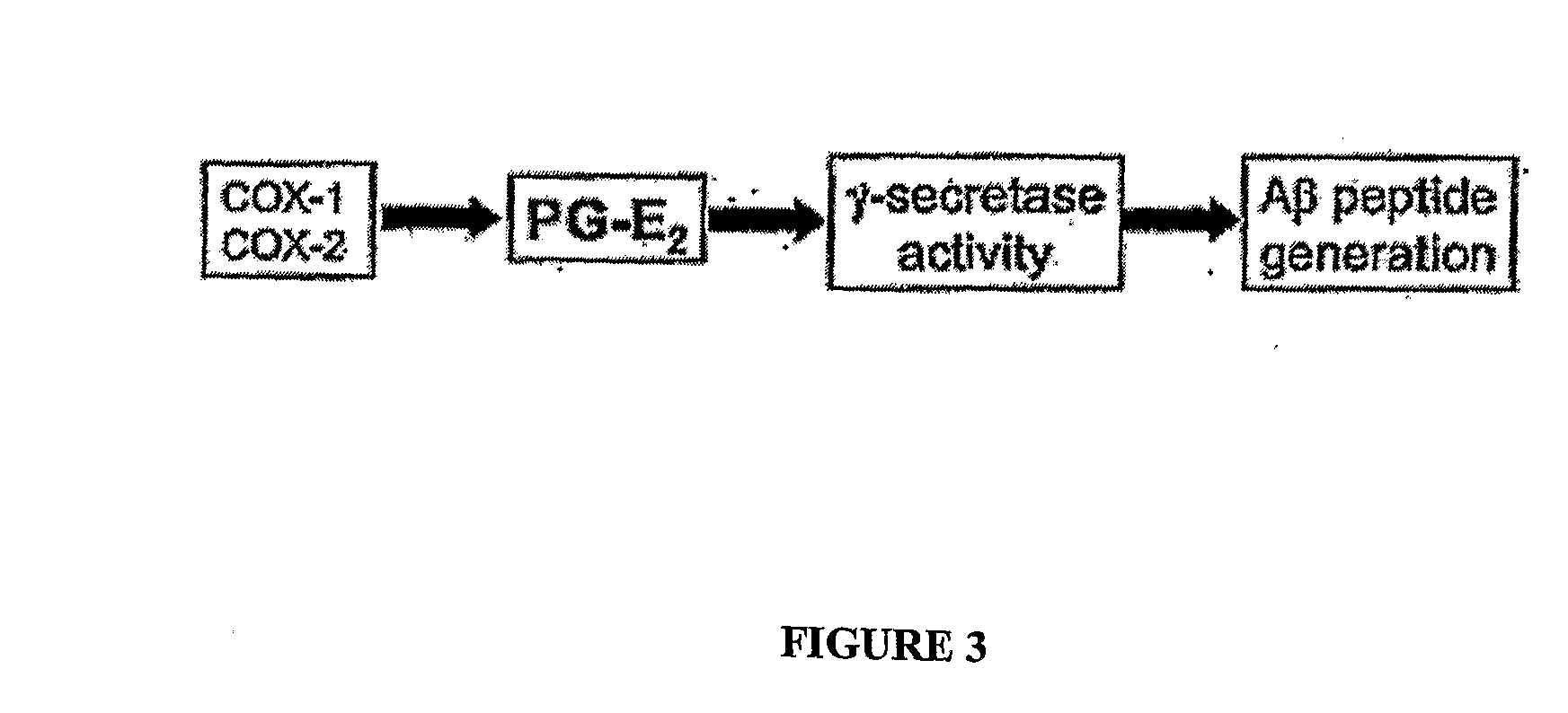

Nitroxides for use in treating or preventing amyloid-related diseases

InactiveUS20090042937A1Low serum levelsUseful in treatmentAntibacterial agentsBiocideAntioxidantOxidative stress

Phamaceutical compositions are provided that are useful in treating amyloid protein-related diseases such as Alzheimer's disease. The compositions comprise a pharmaceutically acceptable carrier, and an effective therapeutic or prophylactic amount of a nitroxide antioxidant that downregulates one or more genes related to the amyloid-related disease. Methods are also provided for the use of the pharmaceutical compositions in the treatment or prevention of amyloid protein-related diseases. In a preferred embodiment, the nitroxide antioxidant is Tempol (4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl), and the amyloid protein-related disease is Alzheimer's disease. In a preferred embodiment, the downregulated genes are genes related to inflammation or oxidative stress.

Owner:MATRIX BIOMED INC

Derivatives of 1-oxyl-4-hydroxy-2,2,6,6-tetramethylpiperidine

InactiveUS6080864ASufficient water solubilityPrevent premature polymerizationOrganic compound preparationCarboxylic acid esters preparationAcrylonitrile2,2,6,6-Tetramethylpiperidine

Selected derivatives of 1-oxyl-2,2,6,6-tetramethyl-4-hydroxypiperidine are surprisingly effective as inhibitors to prevent the premature polymerization of acrylic and methacrylic acids, their esters, their amides, vinyl acetate and acrylonitrile in the presence of water. Some of these derivatives are new compounds.

Owner:CIBA SPECIALTY CHEM CORP

Method for preparing carboxylated modified cellulose aerogel under aqueous conditions

InactiveCN104311840AWide variety of sourcesSimple processOther chemical processesFreeze-dryingOxygen

The invention discloses a method for preparing carboxylated modified cellulose aerogel under aqueous conditions. The method comprises the following steps: 1 preparing a carboxylated modified cellulose aqueous dispersion, namely adding a microcrystalline cellulose, 2, 2, 6, 6-tetramethyl-piperidine-1-oxygen free radical (TEMPO), NaClO2 and NaClO solution to a sodium phosphate buffer solution, stirring to react for a period of time under certain conditions, adding absolute ethyl alcohol to terminate the reaction, pouring the solution into a conical flask to keep standing and layered, pouring out a supernatant, and then adding 50% ethanol and water to give the clean and thickly gelatinous carboxylated modified cellulose dispersion to replace the supernatant; and 2 carrying out freeze drying to give the carboxylated modified cellulose aerogel. The method disclosed by the invention has the advantages that the obtained carboxylated modified cellulose aerogel has the maximum Ag<+> adsorption capacity of 1.734mmol / g and the maximum Pb2<+> adsorption capacity of 1.696mmol / g.

Owner:GUANGXI UNIV

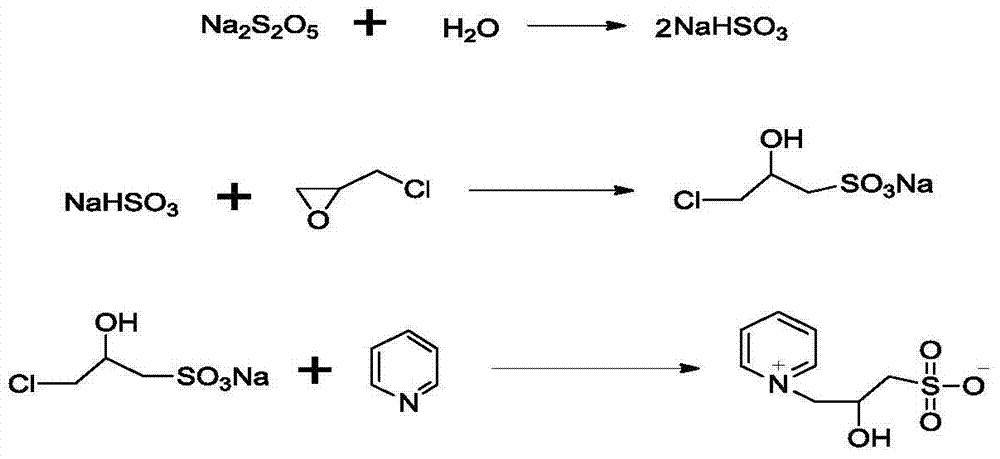

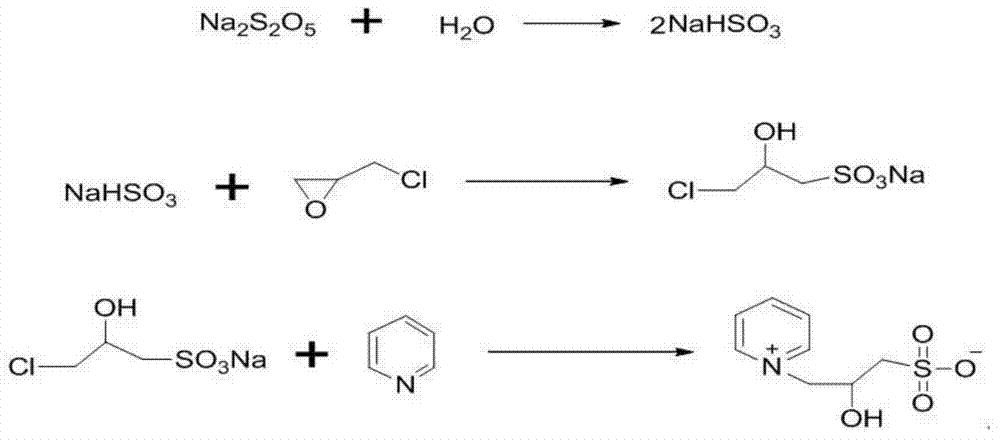

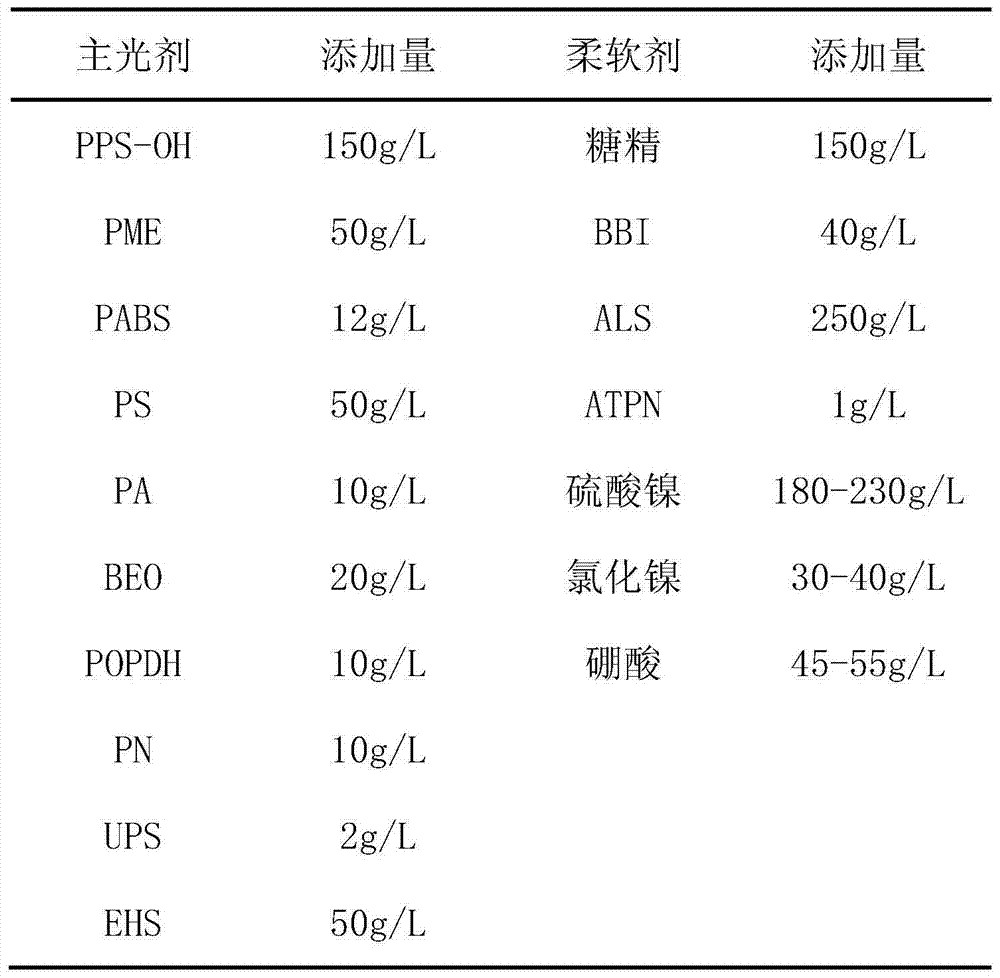

Synthetic method of pyridinium hydroxy propyl sulfobetaine

The invention relates to a synthetic method of pyridinium hydroxy propyl sulfobetaine. The synthetic method comprises the following steps: sufficiently dissolving hydrosulphite or pyrosulfite in water at normal temperature, adding sodium sulfite as an auxiliary sulfonating agent to adjust the pH value of the system to be 5.2-5.5, and then adding polyether F-6 as a catalyst; then adding a complexing agent, controlling the environment conditions, adding epichlorohydrin, and carrying out loop-opening reaction to obtain 3-chloro-2-hydroxy propanesulfonate; adding pyridine to the system, controlling the temperature to carry out reflux reaction, adding triethylamine as an impurity removing agent, reacting for 1 hour, then dehydrating and decoloring, adjusting the pH to 2-5, and adding 4-hydroxyl-2, 2, 6, 6-tetramentylniperidine-1-oxygen radical as a stabilizer and a vitamin C derivative to obtain an aqueous solution of the pyridinium hydroxy propyl sulfobetaine. The pyridinium hydroxy propyl sulfobetaine synthesized by the synthetic method is produced by adopting a one-pot method, which accords with the electroplating industry development demands at present; the pyridinium hydroxy propyl sulfobetaine is low in impurity content, good in appearance and low in production cost.

Owner:湖北吉和昌化工科技有限公司

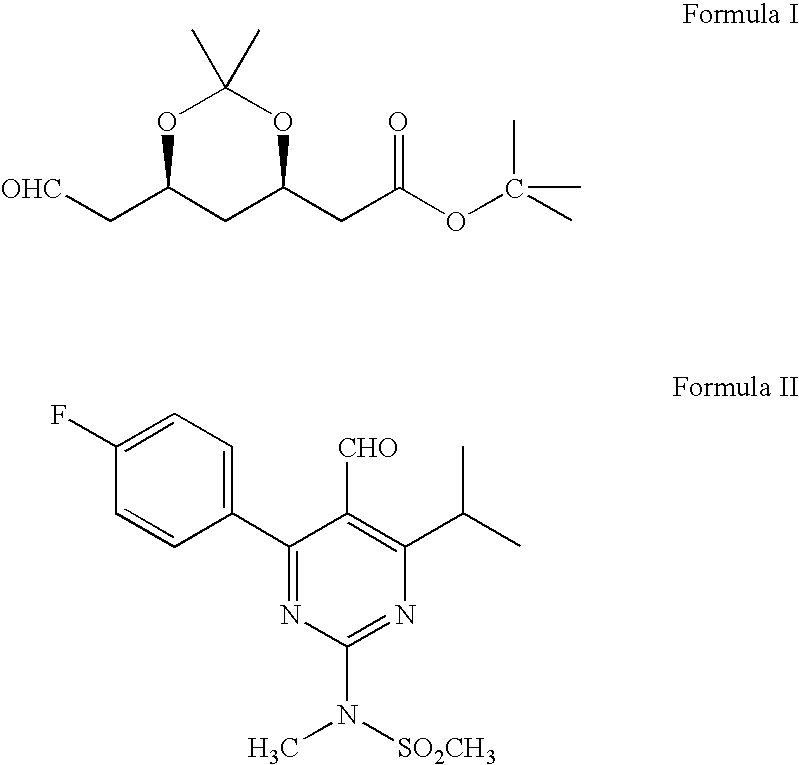

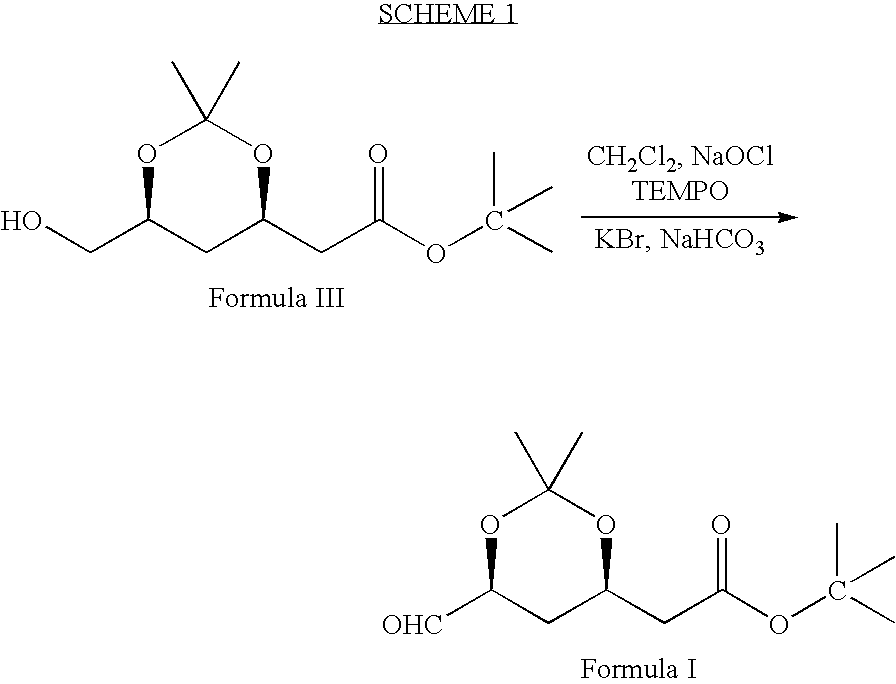

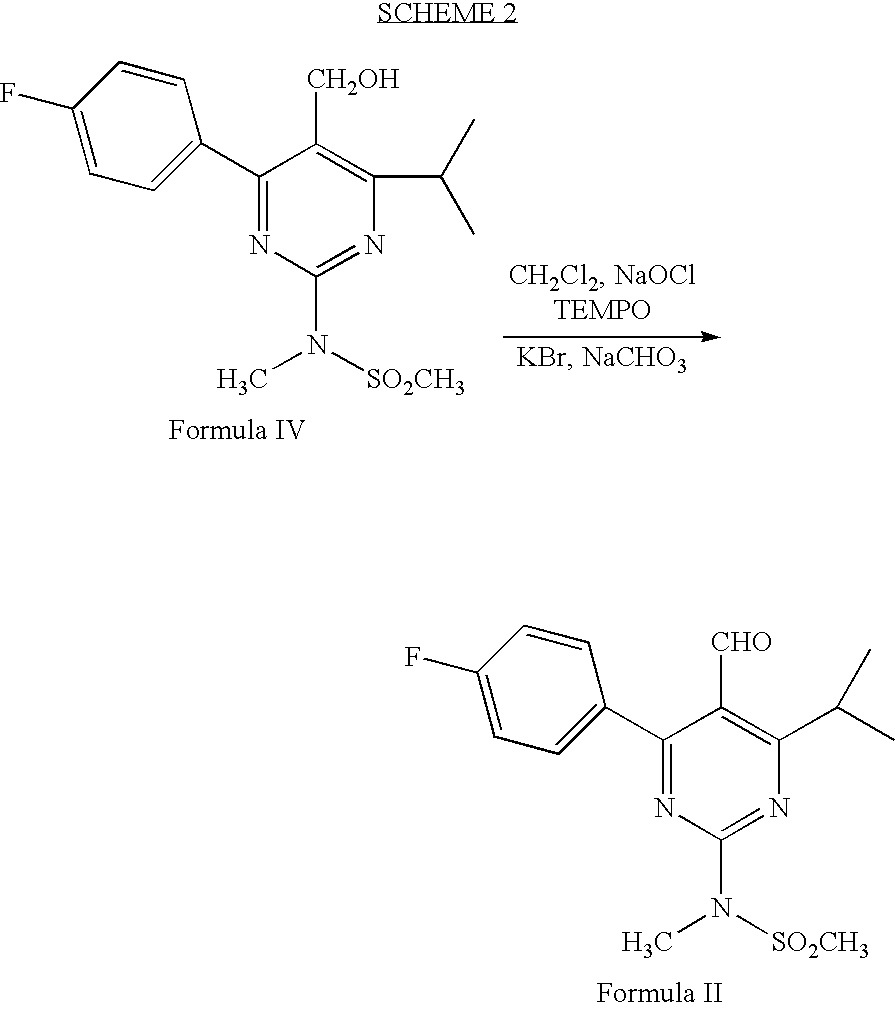

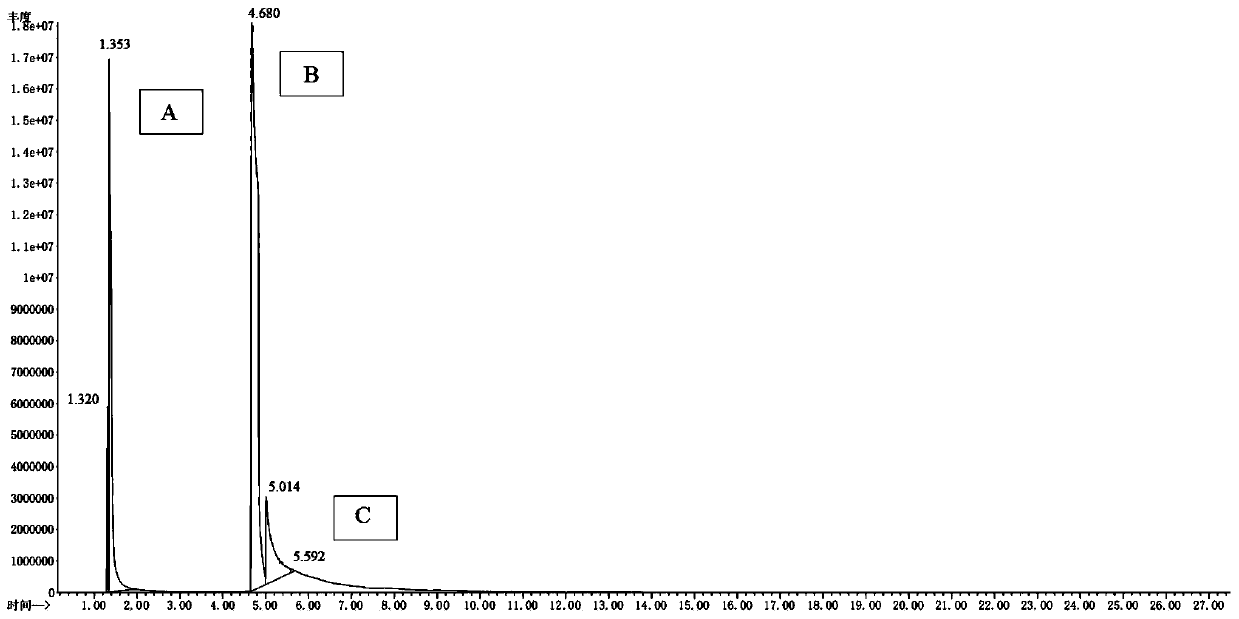

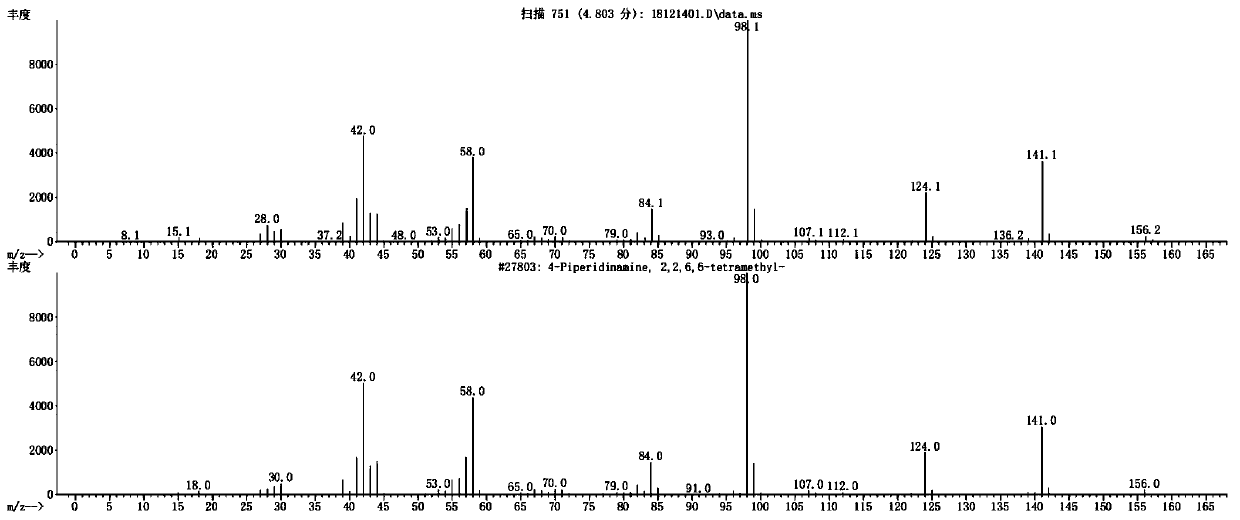

Processes to produce intermediates for rosuvastatin

Intermediate compounds for preparing rosuvastatin are prepared by a process comprising oxidizing hydroxy groups to aldehyde groups, using sodium hypochlorite and 2,2,6,6-tetramethyl piperidinyl oxy free radical (TEMPO) as a catalyst.

Owner:DR REDDYS LAB LTD +1

Synthetic method of amino-2,2,6,6-tetramentylniperidine with specific pH range

PendingCN109836370AReduce ring-opening productsHigh selectivityOrganic chemistryDistillation2,2,6,6-Tetramethylpiperidine

The invention discloses a synthetic method of amino-2,2,6,6-tetramentylniperidine with a specific pH range, and the method comprises the following steps: taking 2,2,6, 6-tetramethyl piperidone as a raw material, adding the raw material and ammonia water into a high-pressure kettle, first adjusting the pH value to 12.0-13.0, adding framework nickel serving as a catalyst, carrying out hydrogenationreaction at temperature of 55-65 DEG C under a set pressure value of 1.5-2.5 mpa, stopping the reaction until the pressure in the kettle is always not lower than 2% of a set pressure value in one hour; and carrying out normal pressure distillation on the reaction liquid, and then carrying out reduced pressure rectification to obtain the product amino-2,2,6,6-tetramentylniperidine. According to themethod disclosed by the invention, the conversion rate of the tetramethyl piperidone is improved, and the product yield is improved.

Owner:安徽新秀化学股份有限公司 +1

Rubber composition for a colored tire

InactiveUS20010056138A1Assess the hardness of the compositionsEvaluate the resistance to thermo-oxidation of the materials testedOrganic chemistrySpecial tyresElastomerPolymer science

The invention concerns a white, light-colored tire rubber composition, devoid of carbon black, comprising at least a diene elastomer, a reinforcing white or colored filler, and an anti-photo-oxidizing system, wherein said protective system comprises (A) a 2,2'-methylene-bis-[4-alkyl (C1-C10)-6-alkyl(C1-C12)phenol]; (B) a dialkylthiodipropionate, the alkyl radicals thereof, which may be identical or different, are (C1-C20), radicals; (C) a 2-(2-hydroxyphenyl) benzotriazole; and (D) a "HALS" amine derived from 2,2,6,6-tetramethylpiperidine.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Process for inhibition of polymerization of (meth)acrylate ester

ActiveUS7241915B2Organic compound preparationPreparation from ortho-estersMeth-2,2,6,6-Tetramethylpiperidine

The present invention provides a process for inhibition of polymerization of a (meth)acrylate ester, which has an extremely higher effect of inhibition of polymerization than in cases where conventional polymerization inhibitors are used. In the process for inhibition of polymerization of a (meth)acrylate ester; an N-oxyl compound and at least one member selected from the group consisting of manganese salt compounds, copper salt compounds, 2,2,6,6-tetramethylpiperidine compounds, and nitroso compounds are used together as polymerization inhibitors, and further an acid is used.

Owner:NIPPON SHOKUBAI CO LTD

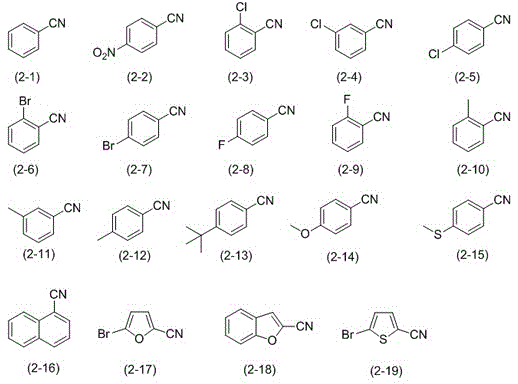

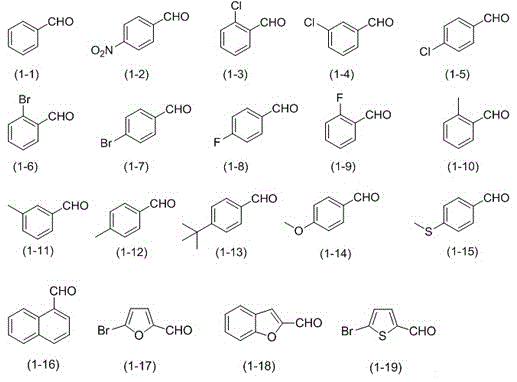

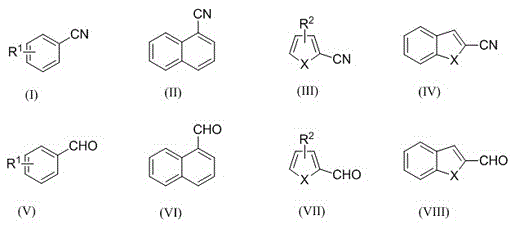

Electrochemical catalytic synthesis method of aromaticnitrile

ActiveCN105543886ASimple and safe operationMild reaction conditionsElectrolysis componentsElectrolytic organic productionElectrolysisSodium tetrafluoroborate

The invention discloses an electrochemical catalytic synthesis method of aromaticnitrile. Aromatic aldehyde is used as a raw material, HMDS (hexamethyldisilazane) is used as a nitrogen source, a three-electrode system is adopted, a negative electrode and a positive electrode adopt platinum electrodes, and a 0.1mol / l silver nitrate acetonitrile solution is used as a reference electrode; aromatic aldehyde, HMDS, TEMPO (2,2,6,6-tetramethyl-1-piperidine-N-oxyl free radicals) and acetic acid are added to an electrolyte acetonitrile solution with certain concentration, the mixture is stirred for an electrolytic reaction at the temperature of 5-40 DEG C and under the constant voltage of 0.5-8.0 V for 5-30 h, a reaction liquid is subjected to aftertreatment, and a product, namely, aromaticnitrile, is obtained; an electrolyte refers to sodium perchlorate, sodium periodate or sodium tetrafluoroborate. The method is simple and safe to operate and easy to implement.

Owner:SHANGHAI LINKCHEM TECH CO LTD

High-quality polymerization inhibitor and preparation technology of same

InactiveCN103030590AGood inhibition effectIncrease added valueOrganic chemistryDistillation2,2,6,6-Tetramethylpiperidine

The invention discloses high-quality 4-methoxyl-2, 2, 6, 6-tetramethylpiperidinol (polymerization inhibitor 705 for short) and a preparation technology of the same. The high-quality polymerization inhibitor is prepared by the processes of: firstly, preparing tetramethylpiperidinol, and then, carrying out mixing, oxidizing, filtering, molecular distillation, packaging and on the like. The technology for preparing the polymerization inhibitor 705 comprises carrying out oxidization on tetramethylpiperidinol and acetaldehyde. According to the technology disclosed by the invention, the polymerization inhibitor 705 is obtained by molecular distillation and purification, thus, high-quality products can be provided for the clients and the company.

Owner:南通市振兴精细化工有限公司

Polyolefin resin composition and foam molded article

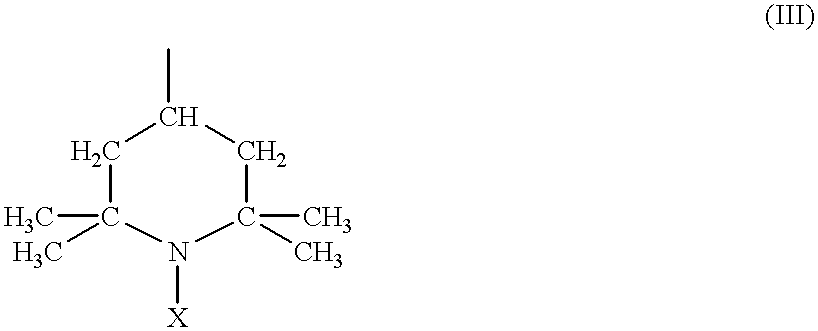

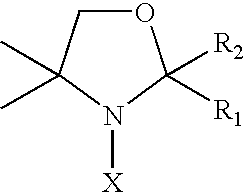

A resin composition, comprising (A) a polyolefin resin, (B) a foaming agent, (C) a black pigment, and 0.05 to 5 parts by mass of (D) a hindered amine light stabilizer which satisfies the following requirements (a) and (b), provided that the content of the polyolefin resin (A) is let be 100 parts by mass:requirement (a): having a 2,2,6,6-tetramethylpiperidyl group represented by formula (I) that is attached to any of a carbon atom, an oxygen atom and a nitrogen atom:requirement (b): having an acid dissociation constant (pKa) of less than 8.

Owner:SUMITOMO CHEM CO LTD

Clean production process of 2-thiopheneacetic acid

ActiveCN104725345AMild reaction conditionsEnvironmental protectionOrganic chemistryAcetic acidNitrogen oxides

The invention relates to the chemical organic synthesis field and particularly discloses a method for preparing environment-friendly 2-thiopheneacetic acid with mild reaction condition. The 2-thiopheneacetic acid is prepared by taking 2, 2, 6, 6-tetramethyl piperidine nitrogen oxide (TEMPO) or the derivative as a catalyst and oxidizing 2-thiophene-ethanol through an oxidant such as sodium hypochlorite and sodium chlorite. The process is mild in reaction condition, high in reaction selectivity (95%), high in conversion rate (100%), high in yield (85%) and easy to be industrially operated.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

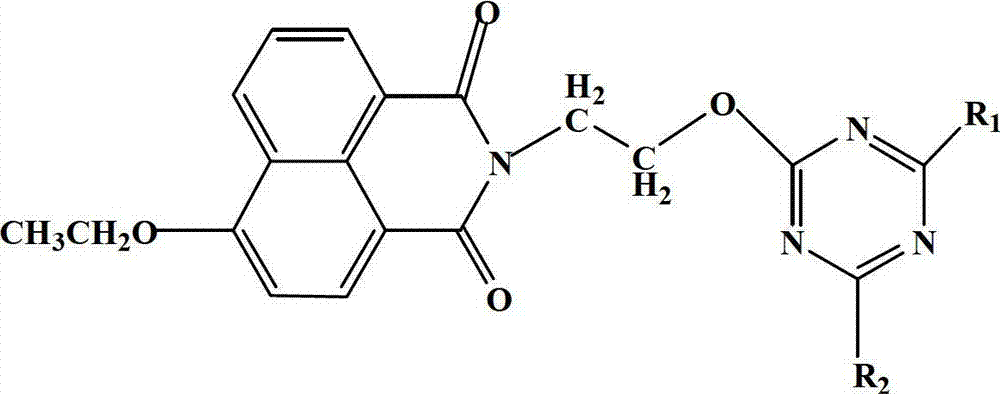

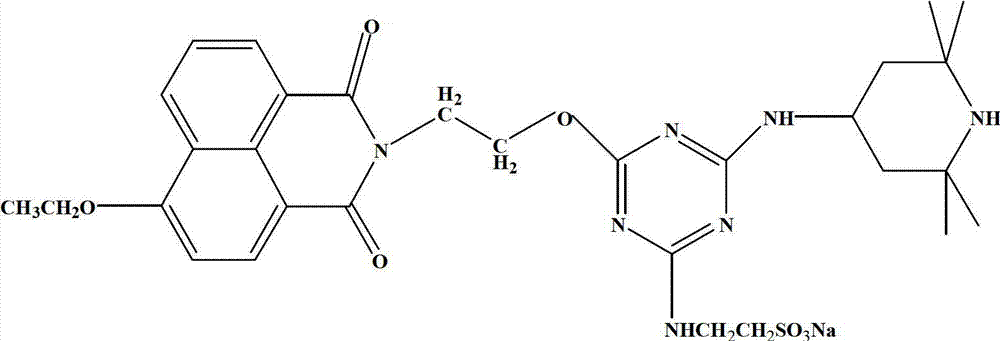

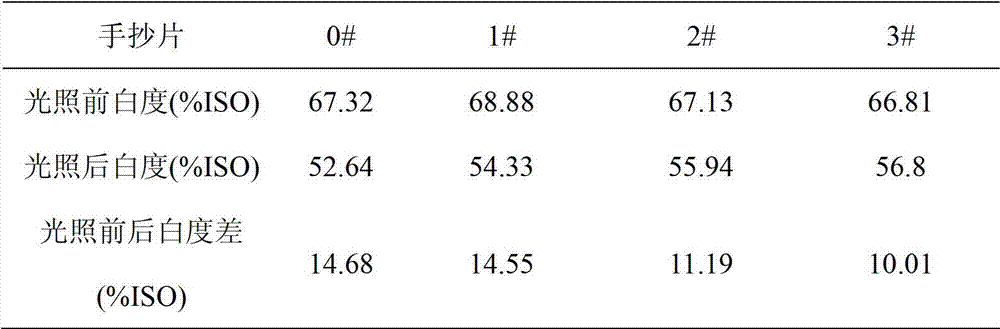

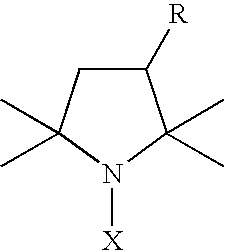

Yellowing inhibitor based on naphthalimide fluorescent whitening agent, and preparation method and application thereof

ActiveCN102887888AGive full play to synergistic advantagesSuccessful designOrganic chemistryLuminescent/fluorescent substance additionWhitening Agents2,2,6,6-Tetramethylpiperidine

The invention discloses a yellowing inhibitor based on naphthalimide fluorescent whitening agent, and a preparation method and application thereof. The preparation method comprises the following steps: taking cyanuric chloride as a crosslinking monomer, introducing free group trapping agent 2,2,6,6-tetramethyl piperylhydrazine or 2,2,6,6-tetramethyl piperidinol and naphthalimide fluorescent whitening agent into the same molecule, and further introducing an amino water-soluble compound, thus synthesizing a new pulp yellowing inhibitor having high yield. According to the invention, multiple functional groups are grafted in the same molecular structure, the yellowing of paper pulp is inhibited through multiple mechanisms and approaches, and the novel concept of multifunctional molecule design is embodied; and the yellowing inhibitor has a favorable effect of inhibiting the yellowing of paper pulp.

Owner:南京旭美化工有限公司

Nitroxides for use in treating predisposed or at risk patients

Pharmaceutical compositions are provided that are useful in treating diabetes. The compositions comprise a pharmaceutically acceptable carrier, and an effective therapeutic or prophylactic amount of a nitroxide antioxidant that alters the expression of genes related to diabetes. Methods are also provided for the use of the pharmaceutical compositions in the treatment or prevention of diabetes. In a preferred embodiment, the nitroxide antioxidant is Tempol (4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl).

Owner:MATRIX BIOMED INC

Method for preparing salicylaldehyde by oxidizing saligenol selectively catalyzed by molecular oxygen

ActiveCN103012092AMild reaction conditionsHigh catalytic activityOrganic compound preparationCarbonyl compound preparationAir atmosphereSalicylaldehyde

The invention relates to a method for preparing salicylaldehyde by oxidizing saligenol selectively catalyzed by molecular oxygen, and belongs to the technical field of catalysts. In the method, saligenol is used as a raw material, the used catalyst is composed of the following components of (A) 2,2,6,6-tetramethyl piperidine-N-oxygen radical (TEMPO), 4-benzoyl-2,2,6,6-tetramethyl piperidine-N-oxygen radical or 4-acetyl-2,2,6,6-tetramethyl piperidine-N-oxygen radical; (B) a brominated salt-bromate salt combination; (C) a nitrite salt; and (D) sulfuric acid, hydrochloric acid, nitric acid or phosphoric acid; and the catalytic oxidation reaction is carried out at a temperature of 10-80 DEG C under an air atmosphere. The method has the following advantages that (1) reaction condition is mild, catalytic activity is high, reaction efficiency is high, and selectivity of a product is high; (2) transition metals particularly precious metal compounds are prevented from use in the catalytic system, the catalytic system is low in cost, is safe and convenient and has small pollutions; and (3) the used inorganic components of the brominated salt-bromate salt combination and the nitrite salt are low in cost and easy to obtain, and the post-treatment after reaction is easy.

Owner:张家港市飞航科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com