Preparation method of nano-silver particle supported nanocellulose antibacterial film

A technology of nano-cellulose and nano-silver particles, applied in the field of organic-inorganic composite materials, can solve the problems of easy agglomeration and uneven dispersion of silver particles, and achieve the effects of being beneficial to health, reducing costs, and solving uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

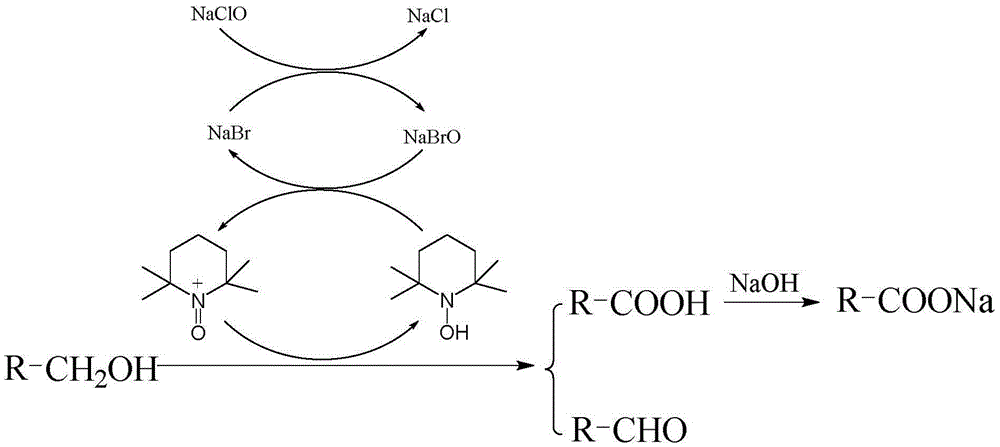

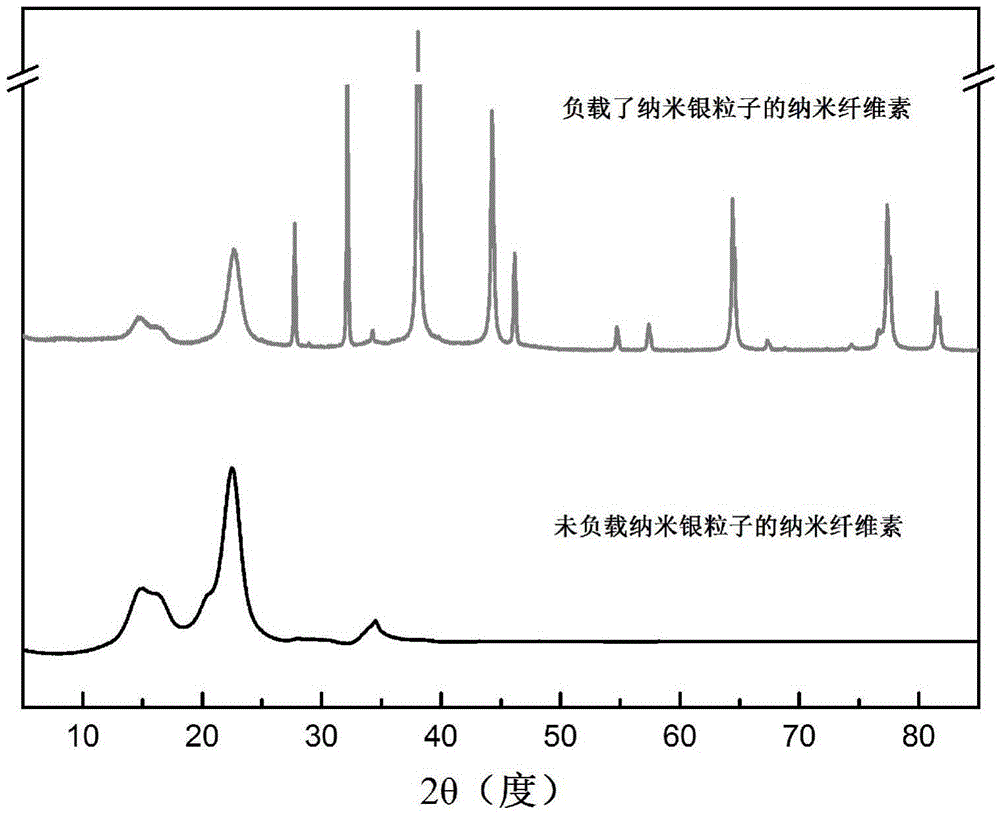

[0033] In the preparation method according to the invention, 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO), sodium bromide and sodium hypochlorite are used to treat the cellulose raw material. The possible mechanism of TEMPO oxidation reaction is as attached figure 1 As shown, the TEMPO oxidation system oxidizes the hydroxyl group on the six-position carbon of cellulose to carboxyl group and / or aldehyde group. This reaction oxidizes the hydroxyl group on the surface of the cellulose, reduces the hydrogen bond content, and reduces the binding force between fibers. In addition, the carboxyl group The formation of cellulose improves the water solubility of cellulose, which is beneficial to the nanonization of cellulose.

[0034] The formed carboxyl group can react with sodium hydroxide to obtain -COONa, wherein the sodium hydroxide can be regarded as the product of sodium bromide strong acid and weak base salt dissolved in water. Then, using Na + with Ag + The ion excha...

Embodiment 1

[0042] (1) Pulverize 2g cotton linter pulp board, immerse in 180ml distilled water, add 0.2g sodium bromide, 0.016gTEMPO and 10ml concentration successively and be the sodium hypochlorite solution of 1mol / L, stir 10h at room temperature, stirring speed is 400rpm, reaction During the process, the pH of the reaction system was adjusted to about 10 with a sodium hydroxide solution with a concentration of 1 mol / L every half hour. After the reaction was completed, the oxidized cellulose was obtained by centrifugation, and the carboxyl and aldehyde contents were measured as 0.59mmolg -1 and 0.33 mmolg -1 . Then disperse the prepared oxidized cellulose in water to prepare 200ml of oxidized cellulose aqueous suspension with a mass fraction of 0.5%;

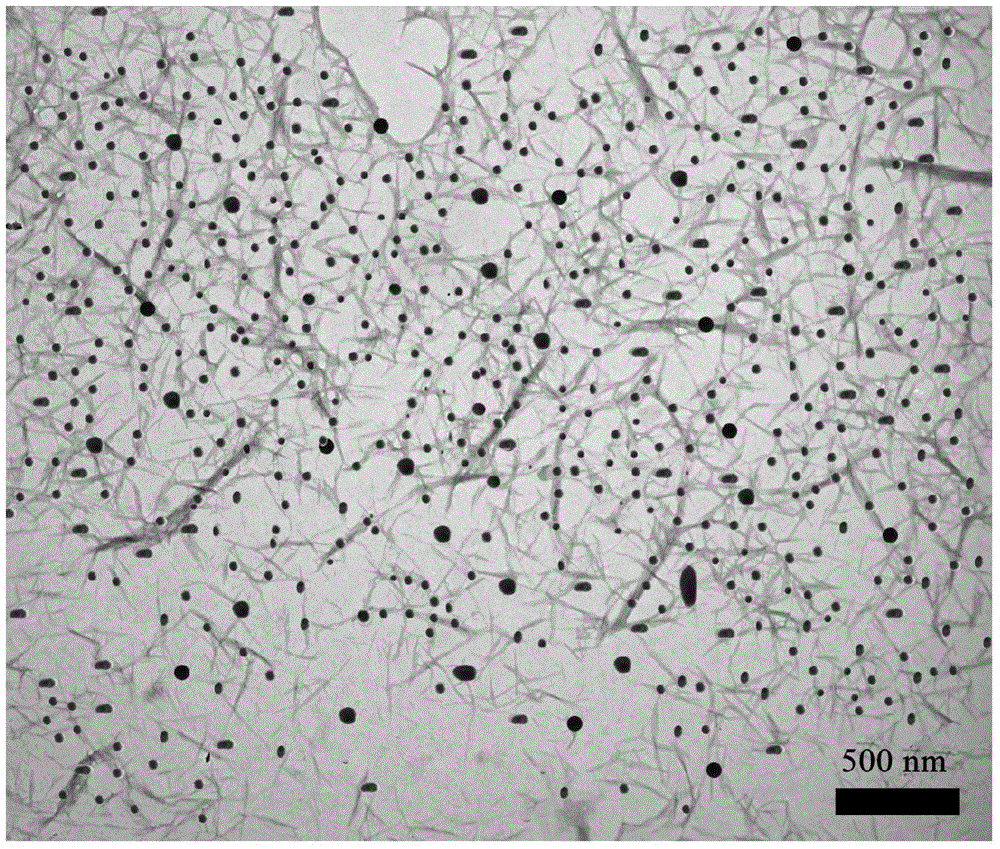

[0043] (2) The oxidized cellulose aqueous suspension obtained above was stirred for 10 minutes at a speed of 15000 rpm, then placed in an ultrasonic cell pulverizer, and treated for 20 minutes at a power of 1000 W to obtain a nanocellul...

Embodiment 2

[0053] (1) Pulverize 2g cotton linter pulp board, immerse in 180ml distilled water, add 0.2g sodium bromide, 0.016gTEMPO and 15ml concentration successively and be the sodium hypochlorite solution of 1mol / L, stir 8h at room temperature, stirring rate is 600rpm, react During the process, the pH of the reaction system was adjusted to about 10 with a sodium hydroxide solution with a concentration of 1 mol / L every half hour. After the reaction was completed, oxidized cellulose was obtained by centrifugation, and the carboxyl and aldehyde content were 0.66 mmolg -1 and 0.23mmolg -1 . Then the prepared oxidized cellulose was dispersed in water to prepare 125ml of oxidized cellulose aqueous suspension with a mass fraction of 0.8%;

[0054] (2) The above-mentioned oxidized cellulose aqueous suspension was stirred for 15 minutes at a speed of 12000 rpm, then placed in an ultrasonic cell pulverizer, and treated for 30 minutes at a power of 800W to obtain a nanocellulose aqueous suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com