Epoxy polymer microsphere immobilized tetramethyl-piperidyl-nitroxide free radical catalyst, as well as preparation method and application method thereof

A technology of tetramethylpiperidine nitroxide free radical and epoxy polymer, which is applied in the field of epoxy polymer microsphere immobilized tetramethylpiperidine nitroxide radical catalyst and its preparation, can solve the problem of non-recyclable , Difficult to separate and recycle, and restrict the development of catalytic systems, etc., to achieve the effects of improving thermal stability, easy separation, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] (1), the embodiment of preparing epoxy polymer microspheres immobilized tetramethylpiperidine nitroxide free radical catalyst:

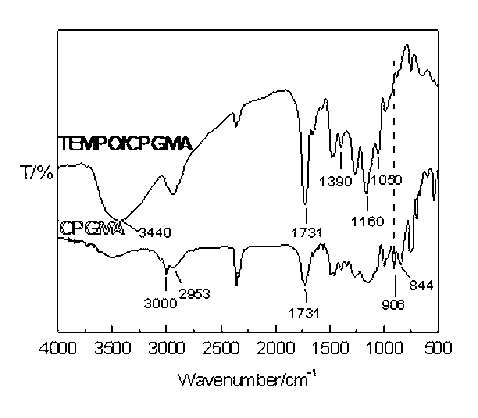

[0018] Example 1: In a four-neck flask, add 1.0g of cross-linked microspheres CPGMA and 20mL of DMF, soak to fully swell the microspheres; weigh 2.14g of 4-OH-TEMPO, dissolve with 30mL of DMF, add to the above solution, and then add 5mL saturated Na 2 CO 3 The solution was protected under nitrogen, reacted at 85°C for 16 hours, filtered, washed the microspheres repeatedly with distilled water and absolute ethanol, and vacuum-dried to constant weight to obtain TEMPO / CPGMA microspheres immobilized by nitroxide radicals. The immobilized amount of TEMPO in the obtained microspheres was 3.14mmol / g.

[0019] Example 2: In a four-neck flask, add 1.0g of cross-linked microspheres CPGMA and 20mL of DMF, soak to fully swell the microspheres; weigh 3.21g of 4-OH-TEMPO, dissolve it with 30mL of DMF, add it to the above solution, and then add 5mL satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com