A kind of green fluorescent protein and layered composite metal hydroxide composite luminescent ultra-thin film and preparation method thereof

A technology of green fluorescent protein and layered compounding, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., to achieve the effect of improving utilization rate, good stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

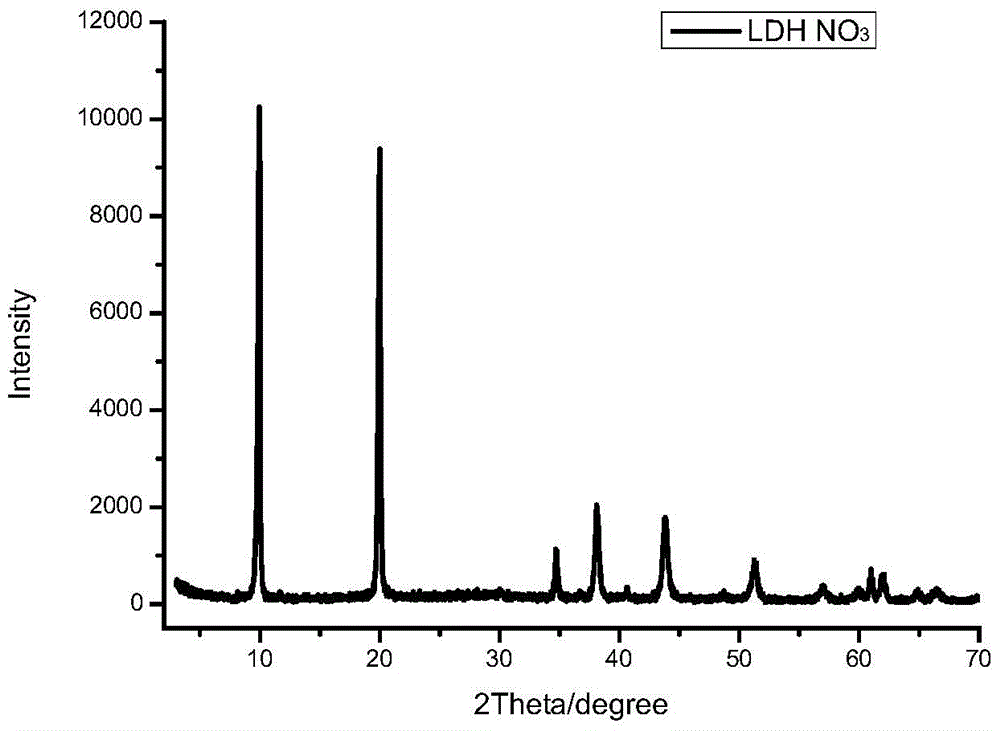

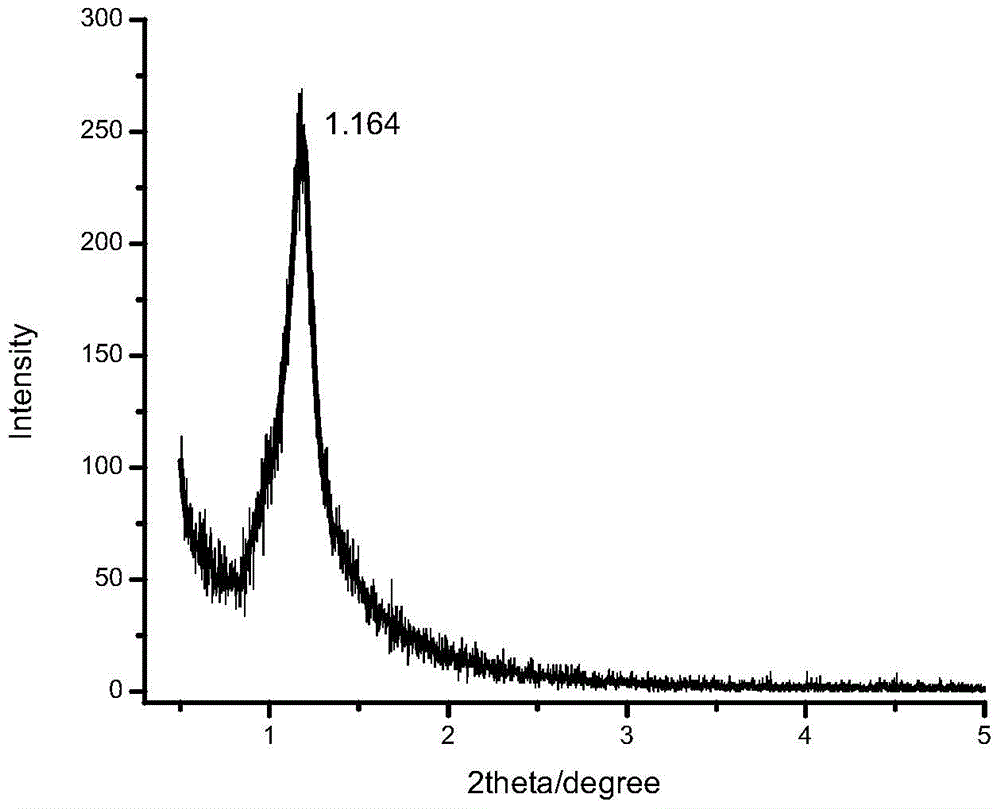

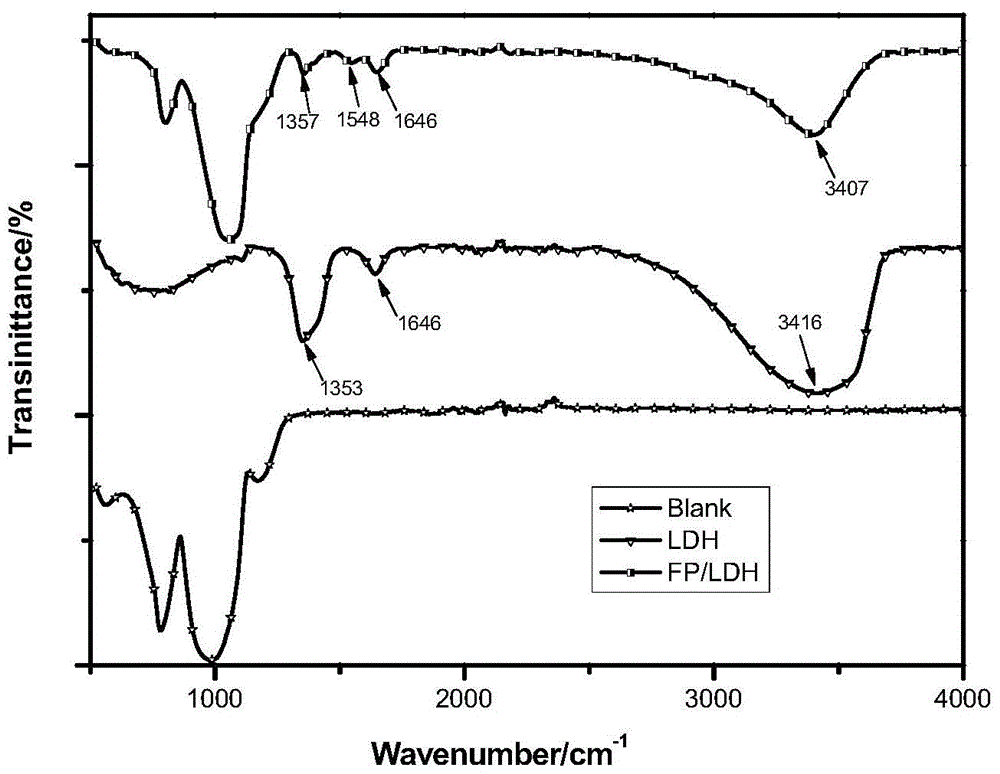

[0030] 1. Prepare LDHs by fast nucleation crystallization isolation method, the specific method is to weigh 15.385gMg(NO 3 ) 2 ·6H 2 O and 11.254g Al(NO 3 ) 3 9H 2 O dissolved in 80ml to remove CO 2 Deionized water, denoted as A solution, Mg 2+ / Al 3+ The molar ratio is 2:1; Weigh 7.2g NaOH and dissolve it in 80ml to remove CO 2 Deionized water, denoted as B solution; A and B two kinds of solutions were added to the total back-mixed liquid membrane reactor at the same time, the slit width between the reactor rotor and the stator was adjusted to 2mm, the working voltage was 140V, and the rotor speed was 5000rpm. The obtained mixed slurry was transferred to a reaction kettle, and after crystallization at 110°C for 24 hours, it was fully washed with deionized water, and the fourth centrifugal liquid was taken as the magnesium-aluminum LDHs colloidal solution. The centrifuged substrate was dried at 60°C for 18 hours to obtain dry magnesium-aluminum LDHs.

[0031]2. Take 1...

Embodiment 2

[0038] 1. Prepare LDHs by hydrothermal method, the specific method is to weigh 15.703g Ni(NO 3 ) 2 ·6H 2 O and 10.129gAl(NO 3 ) 3 9H 2 O dissolved in 80ml to remove CO 2 Ni in deionized water 2+ / Al 3+ The molar ratio is 2:1; weigh 16.8g of hexamethylenetetramine HMT and dissolve it in 120ml to remove CO 2 Deionized water; pour the two solutions into a four-neck flask, mix while stirring, and pass nitrogen gas for 1 hour at the same time, then heat and stir in a water bath at 80°C for 3 days; use to remove CO 2 Centrifuge and wash with deionized water until the pH reaches 6.5-7.0, weigh 5g of the centrifugal substrate (nickel-aluminum LDHs) and dissolve it in 100mL to remove CO 2 Deionized water, nitrogen gas for 30 minutes, put in an oven at 120°C for 12 hours, take it out and centrifuge at a speed of 2000rmp for 30 minutes, and take the supernatant as the nickel-aluminum LDHs colloidal solution.

[0039] 2. With embodiment 1;

[0040] 3. With embodiment 1;

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com