Preparation method and application of a class of polydivinylbenzene-ionic liquid-polyacid catalyst

A technology of polydivinylbenzene and divinylbenzene is applied in the field of catalyst preparation to achieve the effects of high-efficiency catalytic activity and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

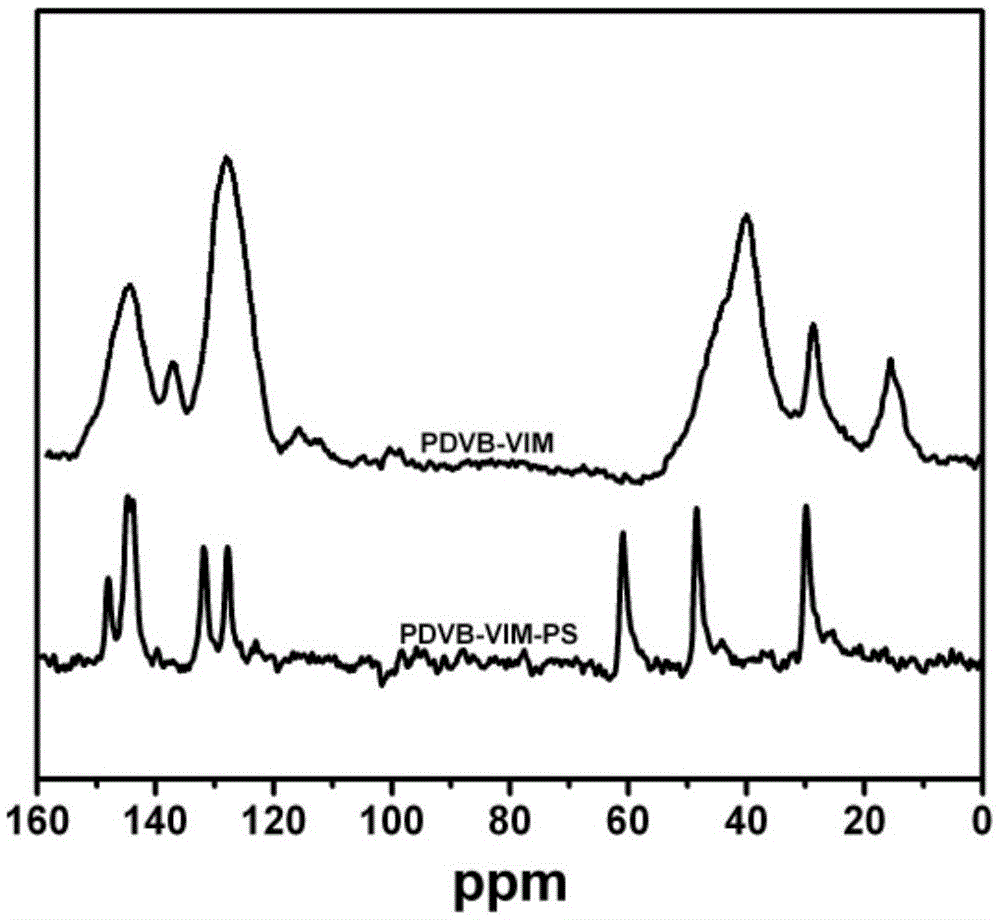

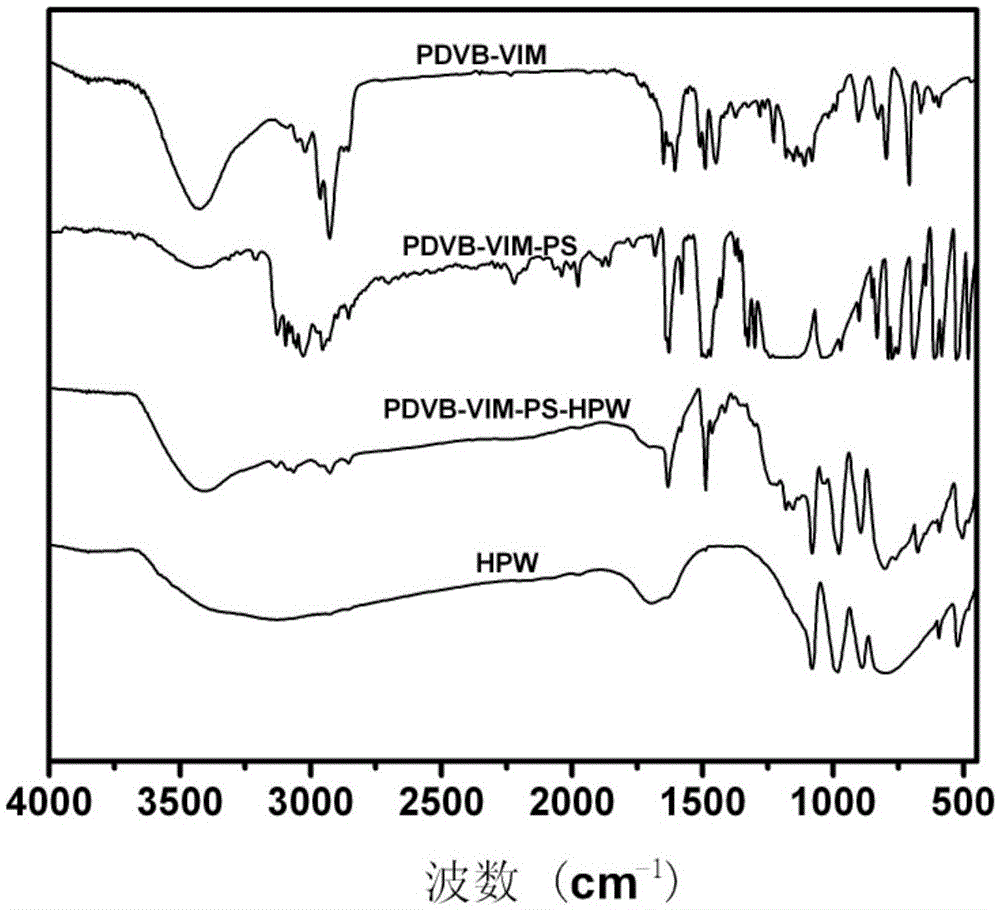

[0020] 1. Add 2.0g of divinylbenzene (PDVB) and 0.5g of 1-vinylimidazole (VIM) to 30ml of ethyl acetate solution containing 0.08g of azobisisobutyronitrile, and stir at room temperature for 2 hours. Keep the temperature in a polytetrafluoroethylene-substrated pressure reaction vessel at a constant temperature for 32 hours in Celsius, and remove the solvent by rotary evaporation under reduced pressure after the reaction is completed to obtain PDVB-VIM;

[0021] 2. Dissolve 1g of the product of step 1 in 30ml of toluene, then add 4g of 1,3-propane sultone (PS), stir at room temperature for 10 hours, filter the product, wash with ether, and remove excess 1,3- Propane sultone was washed and dried in vacuum at 80°C for 12 hours to form PDVB-VIM-PS;

[0022] 3. Add 1.5g of the product in step 2 to 50ml of toluene solution containing 5.76g of phosphotungstic acid (HPW), stir at room temperature for 32 hours, and evaporate the solvent on a rotary evaporator to form polydivinylbenzene-...

Embodiment 2

[0024] 1. Add 2.0g divinylbenzene (PDVB) and 0.7g 4-vinylpyridine (VPY) to 30ml ethyl acetate solution containing 0.08g azobisisobutyronitrile, stir at room temperature for 3 hours, Keep the temperature in a polytetrafluoroethylene-substrated pressure reaction vessel at 100°C for 24 hours, and remove the solvent by rotary evaporation under reduced pressure after the reaction is over to obtain PDVB-VPY;

[0025] 2. Dissolve 1g of the product of step 1 in 30ml of toluene, then add 4g of 1,3-propane sultone (PS), stir at room temperature for 10 hours, filter the product, wash with ether, and remove excess 1,3- Propane sultone was washed and dried in vacuum at 60°C for 12 hours to form PDVB-VPY-PS;

[0026] 3. Add 1.5 g of the product in step 2 to 50 ml of aqueous solution containing 6.2 g of silicotungstic acid, stir at room temperature for 32 hours, and evaporate the solvent to dryness on a rotary evaporator to form polydivinylbenzene-ionic liquid-polyacid Catalyst PDVB-VPY-HPW...

Embodiment 1

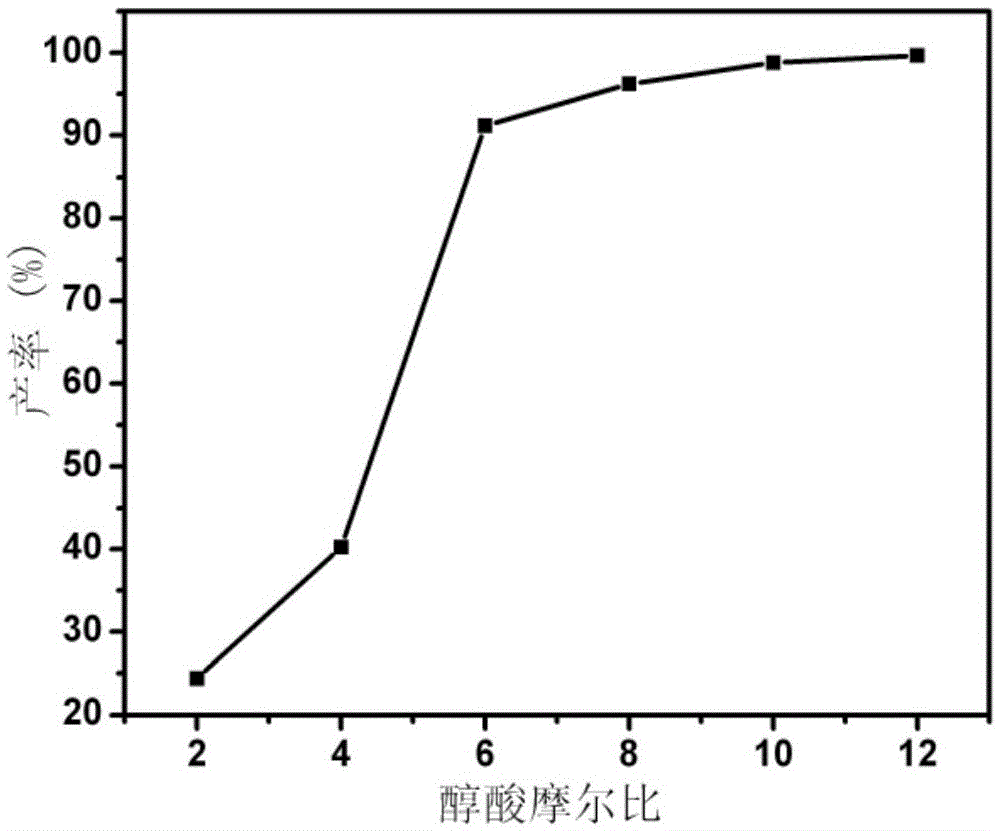

[0028] The catalytic reaction is carried out in a simple glass reactor with magnetic stirring. Weigh 0.05g of the catalyst prepared in Example 1, 7.5mmol of lauric acid, and methanol solutions of different molar ratios, add them into a round bottom flask, and reflux at 65°C for 3h. Do not add catalyst, according to acid: alcohol = 1:6 to do a blank test, for comparison. Use n-hexane as a solvent, methyl tridecanoate as an internal standard, gas chromatography for quantitative analysis, and calculate the yield of the reaction.

[0029] Catalytic results such as figure 2 Shown, the productive rate of blank reaction is only 2.89%, from figure 2 It can be seen that the PDVB-VIM-PS-HPW prepared in Example 1 is used as a catalyst, and when the alcohol: the acid molar ratio reaches 6:1, the productive rate reaches 91.17%, and the catalytic effect is quite obvious; when the alcohol: the acid molar ratio reaches At 10:1 or greater, the yield is close to 99%, with no significant ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com