Microorganic fertilizer against various bacteria and its preparation and use

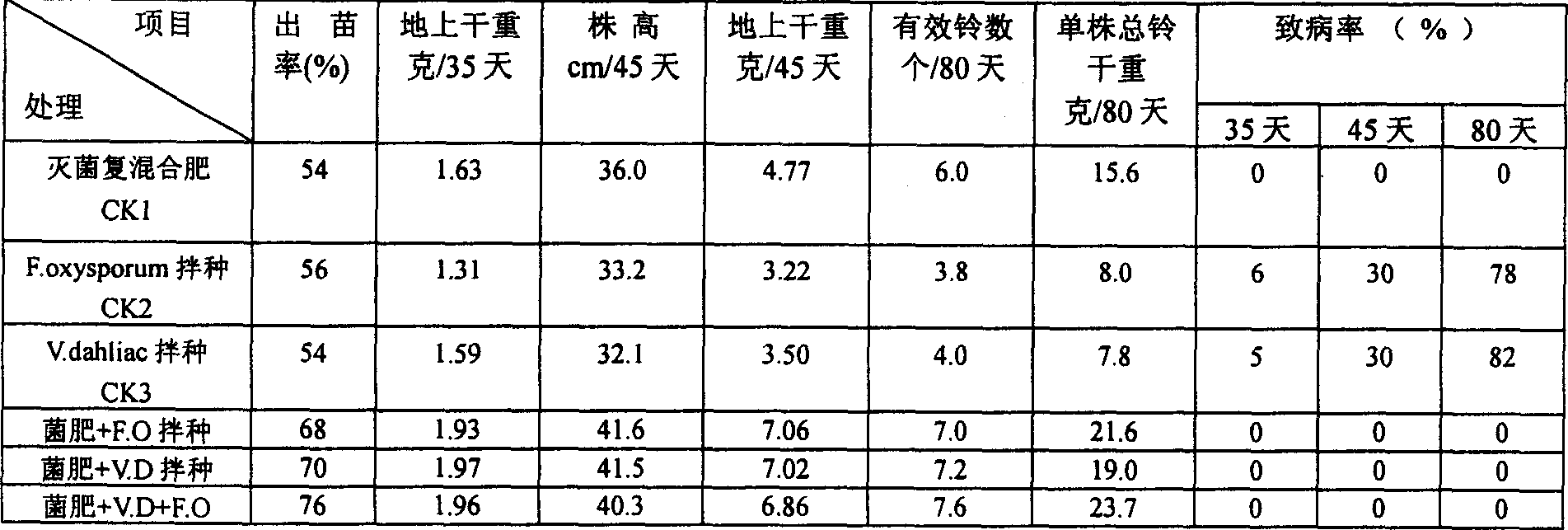

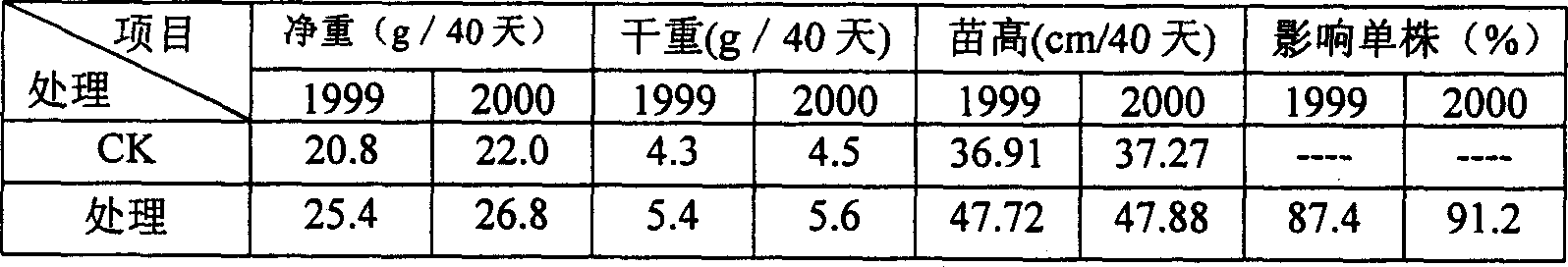

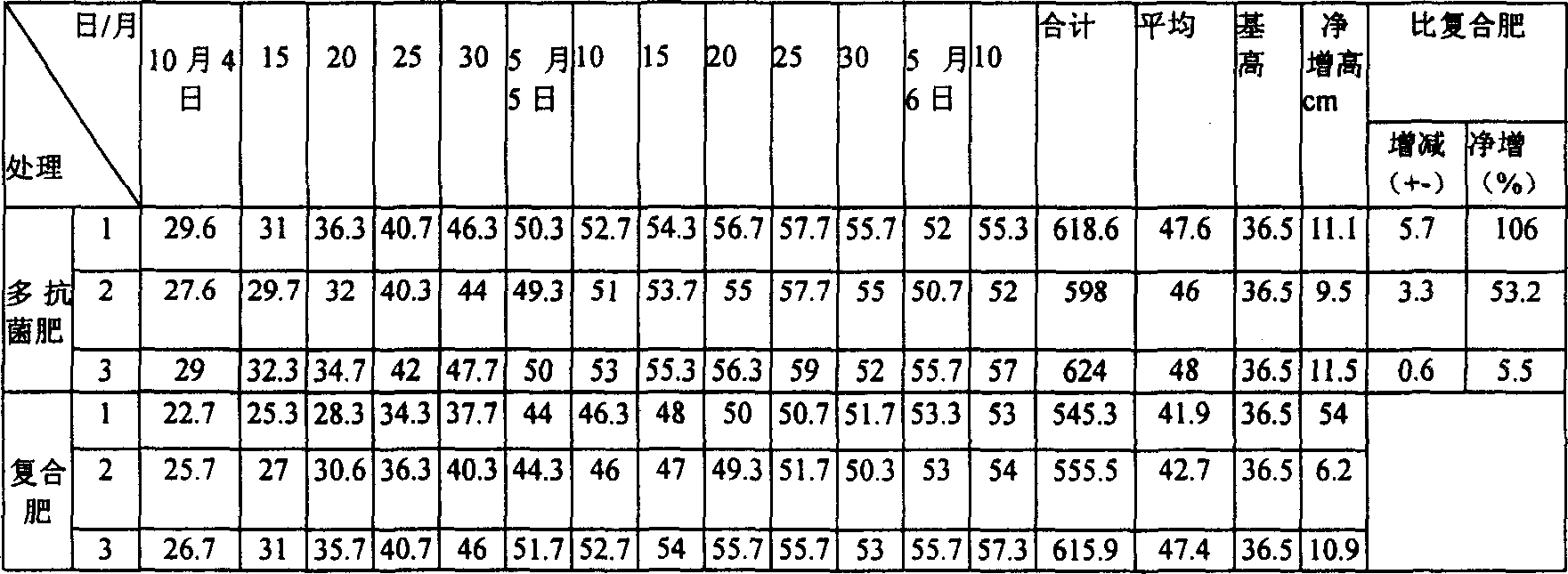

A technology of microbial bacterial fertilizer and multi-antibiotics, applied in biochemical equipment and methods, botanical equipment and methods, microorganisms, etc., can solve the problem that the quick effect of microbial fertilizers is not as good as that of chemical fertilizers, the soil-borne diseases are serious, and the second-generation microbial fertilizers are affected. Development and other issues, to achieve strong inhibitory effect, promote crop growth, and reduce soil-borne diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 jelly-like bacillus fermentation

[0027] 1) Medium: pH: 7.0-7.2

[0028] For slope and shaker: sucrose: 10g; K 2 HPO 4 : 0.5g; MgSO 4 ·7H 2 O: 0.2g; yeast extract: 0.4g; CaCO 3 : 1g; FeCl 3 : 0.005g; add agar for solid culture: 15-20g.

[0029] For fermenter: 0.1% sucrose, 5% corn flour, 1% soybean cake flour, K 2 HPO 4 : 0.05%, MgSO 4 ·7H 2 O: 0.02%, yeast extract 0.04%, CaCO 3 : 0.1%, FeCl 3 : 0.0005%

[0030] 2) Cultivation and fermentation process

[0031] For slant culture: culture at 28°C±2°C for 36-48 hours.

[0032] Erlenmeyer flask liquid shaker culture: 28°C±2°C, cultivate for 36-48 hours, 200 rpm;

[0033] Fermentation in a first-stage fermenter: 28°C±2°C, culture for 36-48 hours, with aeration between 0.1-1 (volume ratio of aeration per minute to fermentation broth).

[0034] Secondary fermenter fermentation: 28°C±2°C, cultivate for 36-48 hours, and the ventilation rate is between 0.1-1 (the volume ratio of the ventilation rate ...

Embodiment 2

[0037] Embodiment 2 Bacillus licheniformis fermentation

[0038] 1) Medium: g / 1000ml distilled water pH: 7.0

[0039] Medium for slant and shake flask: peptone: 5g; NaCl: 5g; beef extract: 3g; additional agar for solid culture: 15-20g (plus for solid culture)

[0040] Medium for fermenter soybean meal 2%, corn flour 10%, K 2 HPO 4 : 0.05%, MgSO 4 ·7H 2 O: 0.02%, yeast extract 0.04%, NaCl: 0.5%,

[0041] 2) Cultivation and fermentation process

[0042] Incline cultivation: 28°C±2°C, cultivate for 36-48 hours.

[0043] Erlenmeyer flask liquid shaker culture: 28°C±2°C, cultivate for 36-48 hours, 200 rpm.

[0044] Fermentation in a first-stage fermenter: 28°C±2°C, culture for 36-48 hours, with aeration between 0.1-1 (volume ratio of aeration per minute to fermentation broth).

[0045] Secondary fermenter fermentation: 28°C±2°C, cultivate for 36-48 hours, and the ventilation rate is between 0.1-1 (the volume ratio of the ventilation rate per minute to the fermentation broth...

Embodiment 3

[0048] Embodiment 3 Jingyang streptomyces fermentation

[0049] 1) Medium: g / 1000ml distilled water pH: 7.2-7.4

[0050] Inclined and preserved with KNO 3 : 1g; NaCl: 0.5g; MgSO 4 ·7H 2 O: 0.5g; K 2 HPO 4 : 0.5g; FeSO 4 ·7H 2 O: 0.01g; soluble starch: 20g; agar: 20g.

[0051] Bran 80% for solid fermentation, rice straw powder 19%, KH 2 PO 4: 0.5%, (NH 4 ) 2 SO 4 : 0.5%, CaCl 2 0.2%

[0052] Material: water = 1: 2.2

[0053] 2) Cultivation and fermentation process

[0054] Incline cultivation: 22°C±2°C. 48 hours

[0055] Erlenmeyer flask solid culture: 22℃±2℃. 48 hours

[0056] Solid fermentation culture: 22℃±2℃. 48 hours

[0057] The resulting culture is hereinafter referred to as bacterial agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com