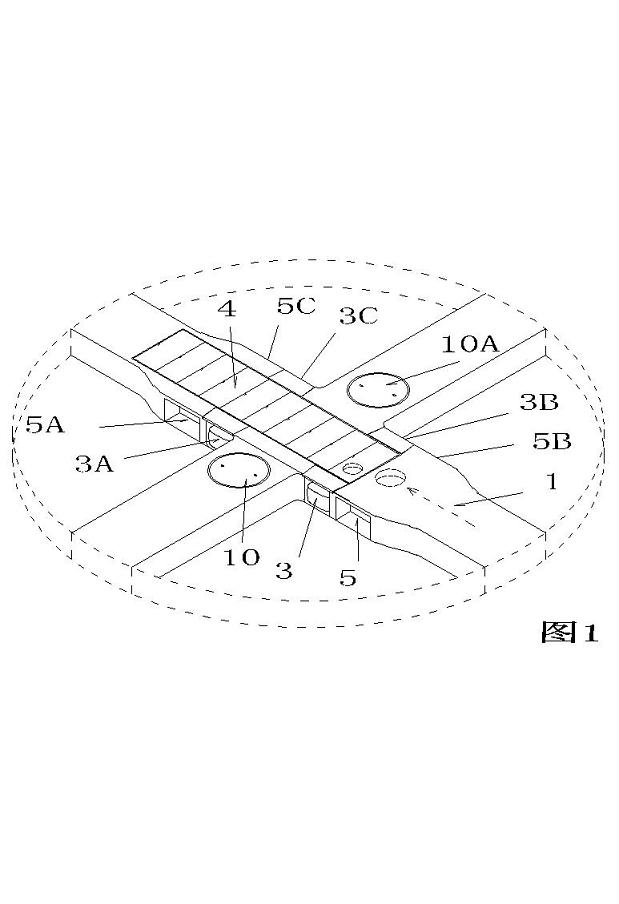

[0004] From the above design, it can be seen that Masonry and rectangular prefabricated pipes are used to form ridge gates, and the inner cavity has a

drainage ditch whose designed total flow height is lower than the bottom level of the cultivated layer along the line. replace the soil ridges in the same direction between the ridges along the two irrigation canals, or the

solid ridges with concrete surface , to overcome the lack of cross-sectional area of the circular tube cavity and the consumption of building materials outside the tube, the most important thing is that the drainage drop is higher than the bottom

level line of the cultivated layer and there is no drainage drop in the flat dam strip field or non-strip field Provide unimpeded drainage

system with sufficient drainage head to prevent irrigation

canal water from harming good fields along the line, timely

discharge irrigation water, rainwater and irrigation canal soaking field water, and drain water from the

system to avoid irrigation

canal water from blocking the drainage outlet or mis-irrigating fields Blocking, avoiding blocking the irrigation mouth, it is necessary to wait for the field water to drain before proceeding, which wastes a lot of

waiting time, and allows the irrigation canal to accept the drainage of the field when the irrigation canal needs to be connected in series. The river flows to other irrigation canals downstream, reversing the status quo of low-yield flooded fields and lower wet fields, promoting

crop growth, drainage canals and aisles and ridges, avoiding delayed water closure or drainage damage to adjacent fields, affecting farming and causing disputes over soaked fields, and reversing soil ridges It is often attacked by

frost, washed by heavy rain, and damaged by drought and cracks, resulting in long-term labor to repair the backward appearance of sick field ridges, and avoiding the role of perennial labor-intensive cleaning of weeds on the edge of the field; the cavity above the total flow height is designed to

discharge heavy rain water, reducing the flood pressure of irrigation canals, and avoiding the flooding of large fields along the line by heavy rains and drowning crops, resulting in the loss of the season; The ridge gates along the line are respectively set on the two side walls of the field ridge next to the crossing field corners, corresponding to each other. , it plays the role of reducing the construction cost of the field ridge and saving the construction materials of the ridge body by using one sinkhole and a set of cover plates for multiple gates; At the crossing of the field ridge with a gate, there are sinkholes and covers beyond the vicinity of the gate at the end of the place , the sinkhole plays the role of depositing sundries that fall into the

ditch by mistake, preventing them from entering the

ditch (

sediment will be washed away with water under the condition of

water pressure and will not deposit), and ensuring the smooth flow of the ditch in the ridge. The cover plate is Outlets for regular clearing of sunken objects; The bottom of the ridge has a

substructure beyond the side walls at both ends , to enhance the self-

bearing capacity of the field ridge (that is, the

drainage ditch) and avoid the deflection of the ridge body; The field ridge sinkhole section is composed of the bottom structure and

brick masonry side walls plus a cover plate , to facilitate the balance of the ridge surface span between the upper and lower fields, to set several gates at both ends of the

cross field corner, to set the cover plate retaining edge and squatting edge body; The remaining sections are a plurality of rectangular prefabricated pipes that are connected together on the underlying structure by

cement mortar. The cross-sectional connection joints between the

pipe bodies are connected by the cross-section joints, the inner end side wall barrier mold, and the cross-section connection gap of the barrier.

Cement mortar is poured into the side wall of the inner end, so that the prefabricated

pipe is densely packed along the bottom structure to form a whole , wherein the prefabricated

pipe plays the role of prefabricating the required pipe materials in advance and increasing the laying speed, and the barrier mold is used to force the gap to be uniform and show the entire connection seam, which is convenient for pouring

cement mortar into the seam and filling the seam tightly. , prevent the mortar from leaking and abdicating, save

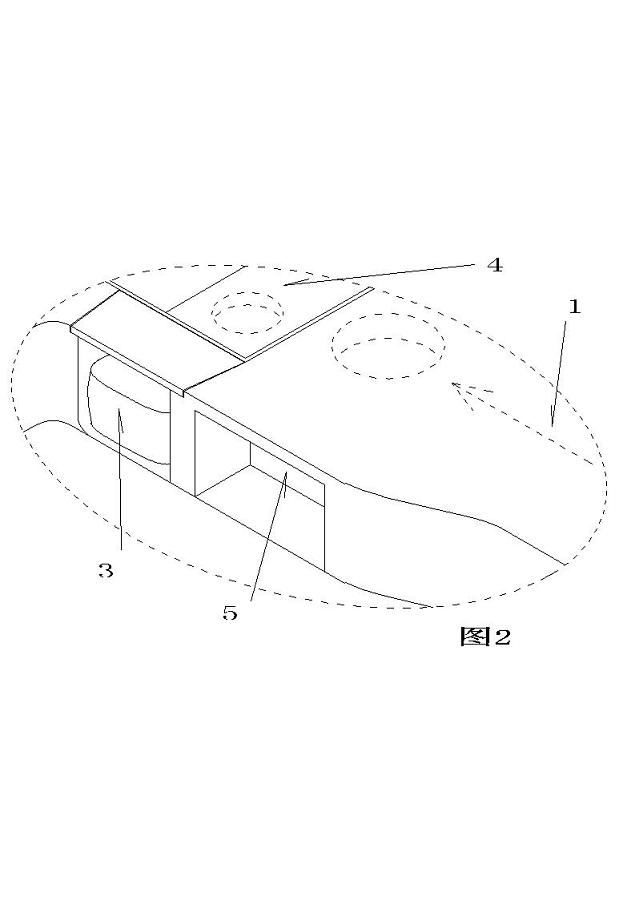

cement mortar and realize the high-quality purpose of effective airtight connection; There is an arch phenomenon under the top of the prefabricated tube inner cavity or

rounding at both ends of the top ; Play the role of increasing the strength of the ridge cavity, especially increasing the

compressive strength of the top structure, so as to reduce the design thickness of the cavity; The prefabricated pipe ridge body consists of a ridge body that is integrally built with a

brick side wall and a cover plate with an arched phenomenon on the bottom surface. , play the role of taking local materials and using them, that is, consuming excess bricks; The drainage ditches within the scope of each field block of the ridge each have a section of sinking bend or arc-shaped sinking bend, each of which is located at the outer part of the downstream end of each sinkhole, and each of the bends The bottom of the top structure has a corresponding arc-shaped sinking part , which can not only increase the thickness of the top structure of the field ridge, ensure that the

agricultural machinery crosses without breaking the top structure, but also does not reduce the cross-sectional area of the inner cavity of the

culvert; The top of the roof structure, the ridges on both sides of the center line are parallel to the ridges at the front and rear ends , play the role of water blocking and passing functions; On the ridge surface other than the two sides, there is a rounded or chamfered downhill that reaches the upper part of the field surface of the side wall, or the surface of the field surface is rough or has anti-skid stripes , to reduce the height of the side walls on both sides of the field ridge, facilitate the horizontal crossing of the field ridge by

agricultural machinery, avoid damage to the lateral sides of the ridge surface, and become a special import and export section for

agricultural machinery across the field ridge; The

dislocation side body formed by the downhill and the side walls at the front and rear ends is a smooth side body with chamfered and rounded shapes,

rough surface or non-slip stripes , its chamfering and

rounding can smooth the

dislocation side body, which is conducive to the oblique crossing of agricultural machinery, and the

rough surface or anti-skid stripes can prevent slipping and slipping; The surface of its top structure is a slightly arched

rough surface or a surface with non-slip stripes , play the role of preventing ridges from accumulating water and road slipping; Apply transparent long-lasting waterproof material to the outer surface above the ridge surface , to prevent the surface from absorbing heat, avoid high road temperature factors caused by frequent

exposure to the hot sun, and sudden heavy rains that cause

thermal expansion and contraction of the masonry ridge, and prevent water from frequently infiltrating into the interior of the surface, which will freeze and crack the masonry in winter The function of protecting the body from the above-mentioned invasion and allowing it to be used permanently; There is

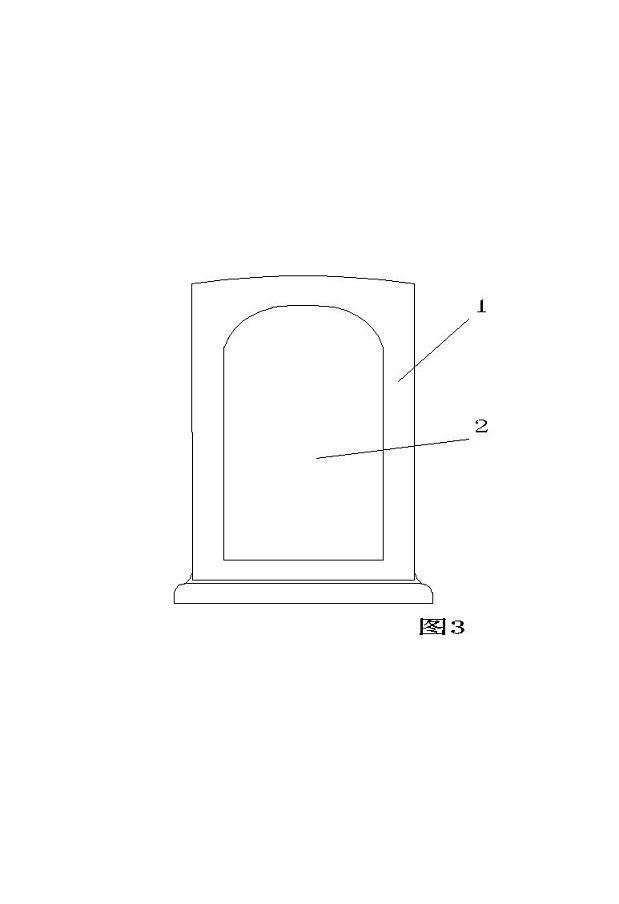

rounding at both ends of the bottom of the gate , which is beneficial to the blocking body to block the side gap of the gate; On the side walls at both ends near the middle section of the gate, there is a vertical rib respectively passing through a baffle barrier. , it plays the role of sealing the ointment-like blocking body in the barrier near the middle section of the gate, preventing the blocking body from abdicating or washing away, and withdrawing the baffle when withdrawing the blocking body; The baffle and the gate at the water inlet end of the baffle are equipped with a bag-sealed ointment-like plug , not loose as a whole, soft and plastic, long-term use, can automatically collapse the gap around the baffle, can control its own height by

extrusion, that is, the water blocking height, and the blocking removal operation does not need to use digging tools, and overcomes the blocking of cement and soil. Field ridges and

impact traffic phenomena, easy to use, labor-saving, time-saving and labor-saving, replace soil blockages, prevent soil blockages from filling canals or drainage ditches in the field, wash away gaps to drain field water, and consume labor all the year round to clear channels and field drainage ditches and gates The plate can not block the side gap and leak water; The plug includes a bag-sealed semi-fluid soft plug , functioning equally to achieve all of the above purposes; The blocking body section of the ridge gate, the upper end has a movable cover plate that is flat on the ridge surface , to pave the ridge surface at one end of the gate, so that the ridge surface along the line is smooth and free of pits, so that you don’t worry about stepping on the pit and falling when you are on the road...; For the rest of the gate, the upper end is a fixed ridge that is flat with the movable cover. , to pave the ridge at the other end of the gate, facilitate traffic and beautify; The side wall of the field surface next to the side wall of the gate has a blocking body storage chamber , it is convenient to store the blocking body and the baffle on the spot, avoiding the need to go home to get the blocking body and the baffle before irrigation, which will waste a lot of round-trip time, and bring the trouble and insufficiency of the blocking body; The height of the blocking body is equal to the height of the field

irrigation water , to play the role of excessive irrigation pouring into the

drainage ditch to flow away from there..., The blocking body can be overlapped to form the required height , to increase the water blocking height; The movable cover plate on the ridge gate is a large-

headed light, thin,

corrosion-resistant hard plate with a narrow water inlet and a wide water outlet. , the

lightness,

corrosion resistance and

hardness of the cover plate are light and durable, and it is easy to remove or cover the cover plate during the irrigation operation, so as to facilitate the placement or withdrawal of the blocking body. The large-headed feature of the cover plate, It plays the role of making the masonry pavement block the cover plate and avoiding the cover plate shifting and falling when stepping on it; There is a protruding part extending into the field at the field surface end of the ridge gate and its associated blockage storage chamber , to ensure that the side wall of the field ridge can be placed down and the side wall can be set up, without increasing the thickness of the side wall along the line, that is, the thickness of the side wall of the drainage ditch; The corner body of the protruding part is a rounded arc-shaped smooth body , which plays the role of

smoothing corners and straight edges and making the appearance beautiful; The design scheme of the drainage ridge gate is implemented in the irrigation canal ridge gate or the open

drainage canal ridge gate , because this design scheme can also reverse the backward appearance of the ridge gates of irrigation canals and open drainage canals; The ridge gates of the two canals and their respective blocking body storage chambers do not extend into the field but are parallel to the side wall of the ridge , because they are

solid field ridges, and the thickness of the ridge body is enough to accommodate the required positions of the blocking body and its sidewall; The blocking body of the ridge gate of the irrigation canal is set at the surface end of the gate , to prevent debris from entering the gate; On the sidewalls at both ends near the middle section of the gate, there is also a vertical retaining edge that passes through a baffle barrier. , also plays the role of blocking the body near the middle section of the gate...; The height of the blocking body reaches the top of the gate, leaving no water turning gap , to prevent the water from the irrigation canal from being poured into the field to infiltrate the field; If necessary, a hidden wire pipe for

power grid will be added along the field ridge. The

design plan is: the wire pipe is made of a crescent-shaped prefabricated block, and the side wall of the field ridge at the bottom, the side wall of the side wall The bottom structure that extends outwards from the bottom is made of

cement mortar through multiple crescent-shaped prefabricated blocks, and then the inner end side wall barrier mold of the cross section joints, and the inner end side wall opening of the cross section connection joint between the prefabricated blocks of the barrier. Let one end of the prefabricated block lean against the outer end of the underlying structure, and the other end lean against the side wall of the ridge below the bottom horizontal line of the cultivated layer to pour

cement mortar, so that the prefabricated block is densely built along the side wall and the underlying structure , wherein the fence mold is also forced to achieve a uniform gap and show the entire connection seam, which is convenient for pouring

cement mortar into the seam, filling the joint tightly, preventing the mortar from leaking out and abdicating, not only saving cement mortar but also realizing effective The role of the high-quality purpose of the airtight connection, the prefabricated block is integrated with the field ridge, not only expands the footing area of the field ridge, but also enhances the structural strength and mutual stability of each other, saves line pipe materials and improves construction progress with this design scheme , The line pipe is laid under the drainage ditch in the field without occupying the cultivated area, less excavation of construction earthwork, no need to spend money and labor to

cut the road concrete, the top of the prefabricated block is buried under the cultivated layer and deviates from the cultivated area, effectively avoiding damage caused by farming The field ridge not only acts as a

protective barrier for the line pipe, but also serves as a ground mark along the line pipe with the ridge body, so as to prevent the line pipe from being accidentally damaged; Surface painted with waterproof ointment , to protect the pipe from being soaked in water; The conduit also includes the laying of multiple prefabricated pipes , play the role of taking local materials and utilizing the existing backlog of products; At the intersection of each

horizontal field ridge, set the

wellhead of the line pipe , play the role of threading into the pipe; The line pipe is laid along the side wall of the field ridge in a straight line along the flow potential, and does not sink with the sinkhole section of the field ridge , it plays the role of preventing the line pipe from creating pits and allowing the rainwater in the pipe to flow away naturally...; At the intersection of the line pipe and the drainage ditch below the

horizontal field ridge, the section of the canal here sinks and passes the line pipe to pass forward , play the role of staggering the

route of the line pipe and not affecting the passage of channels and canals; The inner wall end of the top and bottom ends of the crescent-shaped prefabricated block has a rib extending outward in its own direction, and the outer end of the rib is rounded , also plays the role of achieving all the beneficial effects of "forcing to achieve uniform gap..." mentioned above

Login to View More

Login to View More  Login to View More

Login to View More