Compounded polymerization inhibitor for inhibiting alkyne polymerization

A technology of alkynes and resistance distribution, applied in the purification/separation of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve problems such as safety hazards, affecting heat transfer efficiency, blocking equipment or pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

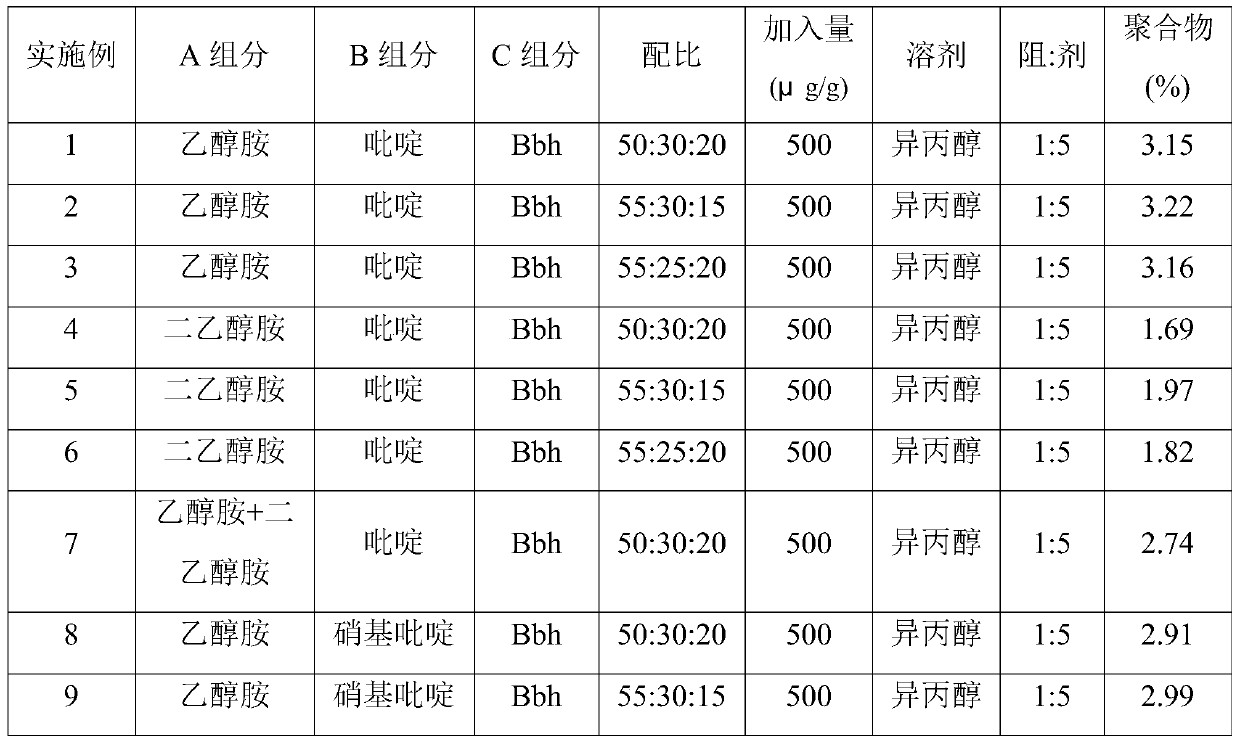

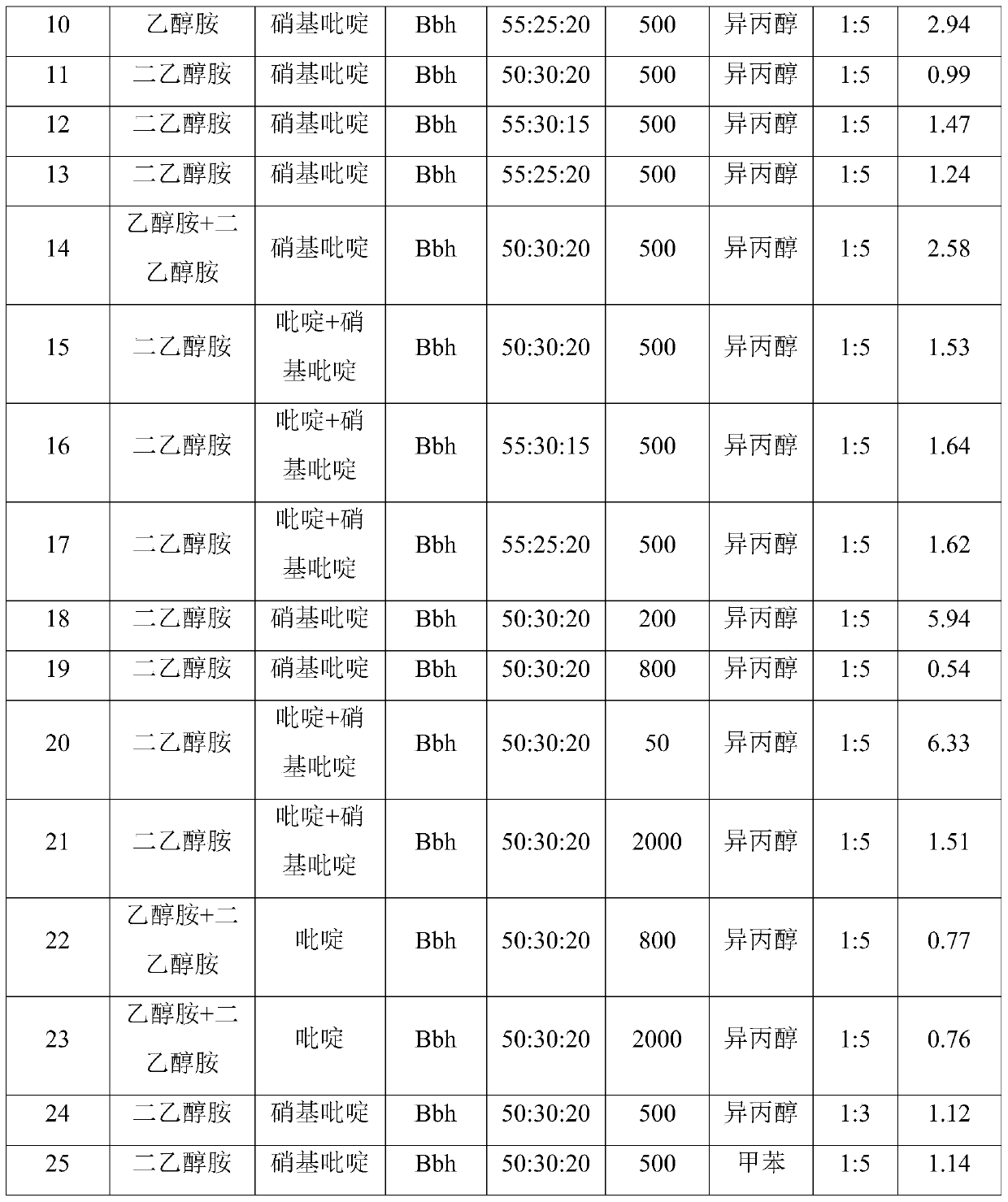

Embodiment 1

[0028] Add 100 parts of analytically pure N-methylpyrrolidone liquid into a stainless steel reactor with jacket heating and stirring; dissolve the compounded polymerization inhibitor in the solvent and add it to the N-methylpyrrolidone liquid; A component is ethanolamine, B component is pyridine, C component is benzaldehyde benzoylhydrazone, the mass ratio of A component, B component and C component is: 50:30:20, and the solvent is isopropanol , the mass ratio of the composite polymerization inhibitor and the solvent is 1:5, based on the total mass of the N-methylpyrrolidone solution after adding the composite polymerization inhibitor and the solvent, the addition of the composite polymerization inhibitor is 500 μg / g; The mixed gas of alkyne was passed through by bubbling to make it fully absorbed and dissolved; after 50 hours, the N-methylpyrrolidone solution dissolved in the mixed gas of alkyne was sampled, and the total polymer production was analyzed by HP7890 gas chromatog...

Embodiment 2

[0030] Add 100 parts of analytically pure N-methylpyrrolidone liquid into a stainless steel reactor with jacket heating and stirring; dissolve the compounded polymerization inhibitor in the solvent and add it to the N-methylpyrrolidone liquid; A component is ethanolamine, B component is pyridine, C component is benzaldehyde benzoylhydrazone, the mass ratio of A component, B component and C component is: 55:30:15, and the solvent is isopropanol , the mass ratio of the composite polymerization inhibitor and the solvent is 1:5, based on the total mass of the N-methylpyrrolidone solution after adding the composite polymerization inhibitor and the solvent, the addition of the composite polymerization inhibitor is 500 μg / g; Under the conditions of 115°C and 0.1MPa, the mixed gas of alkyne was introduced by bubbling to make it fully absorbed and dissolved; after 50 hours, the N-methylpyrrolidone solution dissolved in the mixed gas of alkyne was sampled and analyzed by HP7890 gas chrom...

Embodiment 3

[0032] Add 100 parts of analytically pure N-methylpyrrolidone liquid into a stainless steel reactor with jacket heating and stirring; dissolve the compounded polymerization inhibitor in the solvent and add it to the N-methylpyrrolidone liquid; A component is ethanolamine, B component is pyridine, C component is benzaldehyde benzoylhydrazone, the mass ratio of A component, B component and C component is: 55:25:20, and the solvent is isopropanol , the mass ratio of the composite polymerization inhibitor and the solvent is 1:5, based on the total mass of the N-methylpyrrolidone solution after adding the composite polymerization inhibitor and the solvent, the addition of the composite polymerization inhibitor is 500 μg / g; Under the conditions of 115°C and 0.1MPa, the mixed gas of alkyne was introduced by bubbling to make it fully absorbed and dissolved; after 50 hours, the N-methylpyrrolidone solution dissolved in the mixed gas of alkyne was sampled and analyzed by HP7890 gas chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com