High-efficiency environmentally-friendly polymerization inhibitor of styrene

A high-efficiency polymerization inhibitor, styrene technology, used in the purification/separation of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of high requirements for polymerization inhibitors, improve the polymerization inhibition effect, and enhance the polymerization inhibition. effect, effect of reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

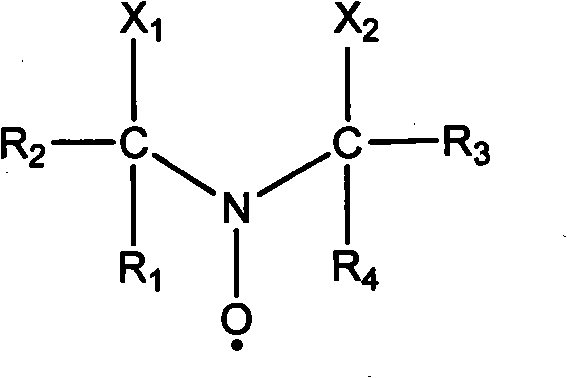

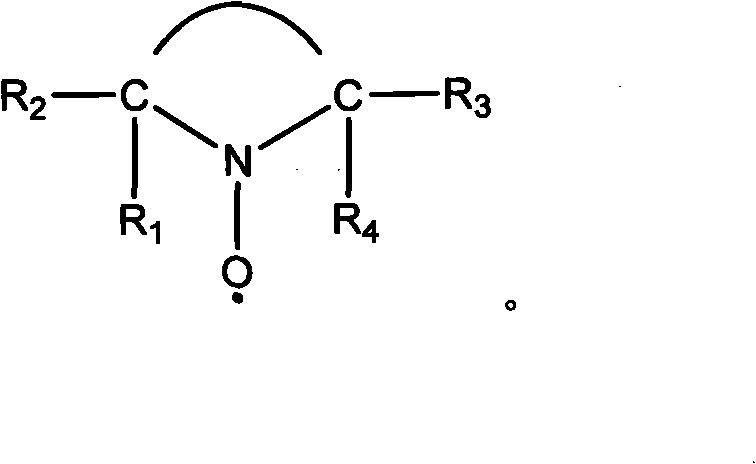

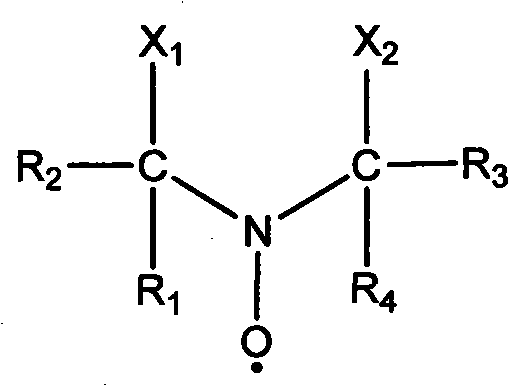

[0025] Dissolve the composite inhibitor system into styrene to form a polymerization inhibitor solution, then add it to purified styrene, and react at 120°C. Take an appropriate amount of reaction solution at regular intervals and use the refractive index method to measure the viscosity of the polymer. Generation volume. The mass of each component of the inhibition system is 0.015 part of TEMPO, 0.0125 part of DEHA, 0.0125 part of DNBP and 0.01 part of PDOP (based on the mass of styrene St as 100 parts).

[0026] Reaction time / h

[0027] Note: TEMPO is 2,2,6,6-tetramethylpiperidine nitroxide; DEHA is N,N-diethylhydroxylamine; DNBP is 2,4-dimethyl-6-sec-butylphenol; PDOP is monophenyl diisooctyl phosphite

Embodiment 2

[0029] Dissolve the composite inhibitor system into styrene to form a polymerization inhibitor solution, then add it to purified styrene, and react at 120°C. Take an appropriate amount of reaction solution at regular intervals and use the refractive index method to measure the viscosity of the polymer. Generation volume. The mass of each component of the inhibition system is 0.015 part of TEMPO, 0.0125 part of DEHA, 0.0525 part of DNBP and 0.02 part of PDOP (based on the mass of styrene St as 100 parts).

[0030] Reaction time / h

[0031] Note: TEMPO is 2,2,6,6-tetramethylpiperidine nitroxide; DEHA is N,N-diethylhydroxylamine; DNBP is 2,4-dimethyl-6-sec-butylphenol; PDOP is monophenyl diisooctyl phosphite

Embodiment 3

[0033]Dissolve the composite inhibitor system into styrene to form a polymerization inhibitor solution, then add it to purified styrene, and react at 120°C, take an appropriate amount of reaction solution at regular intervals and use the refractive index method to measure the polymer Generation volume. The mass of each component of the inhibition system is 0.03 part of OH-TEMPO, 0.0125 part of DEHA, 0.0525 part of DNBP and 0.01 part of PDOP (based on the mass of styrene St as 100 parts).

[0034] Reaction time / h

[0035] Note: OH-TEMPO is 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide radical; DEHA is N,N-diethylhydroxylamine; DNBP is 2,4-dimethyl-6 - sec-butylphenol; PDOP is monophenylene diisooctyl phosphite

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com