Expandable polystyrene resin bead with high color strength and high light fastness and preparation process thereof

A technology of expandable polystyrene and color strength, which is applied in the field of high color strength and high light fastness color expandable polystyrene resin beads and its preparation, and can solve the problem of affecting the stability of the suspension system and the influence of the kettle Problems such as low utilization rate and production efficiency can achieve the effect of stable and easy-to-control polymerization system, bright and stable color, and high color strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

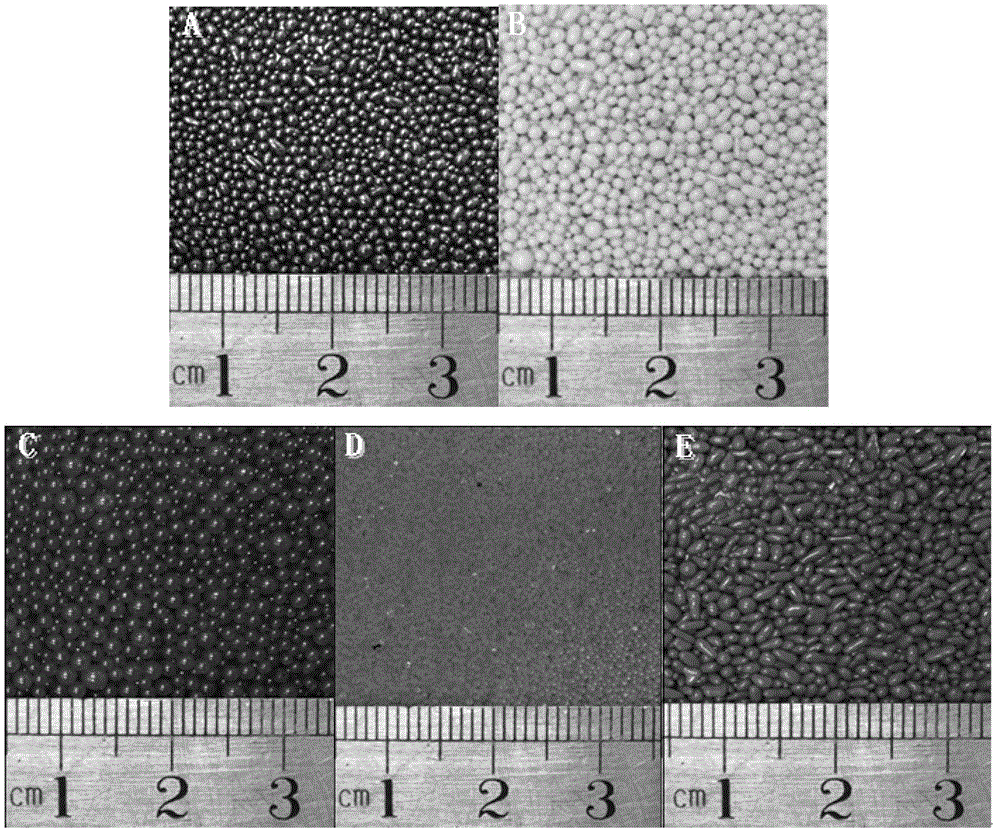

Embodiment 1

[0031] Step 1, preparation of finely dispersed organic pigment paste with high color strength:

[0032] In a three-necked flask with a stirring device, add 100 g of a 5% sodium dodecylbenzenesulfonate aqueous solution, then add 26 g of Pigment Red 168 in the aqueous solution, stir and disperse at a high speed for 0.5 hours, then transfer to a grinder to grind for 5 hour to obtain a red pigment paste with a particle size of about 1 μm;

[0033] Step 2, preparation of monomers containing finely dispersed organic pigments with high color strength:

[0034] Add 20g of butyl acrylate monomer into a three-necked flask with a stirring device, add 0.2g of dihexadecyltrimethylammonium bromide under stirring, and slowly add 0.75g of appealing red pigment color paste dropwise after dissolving, and drop completely Then stir rapidly for 1 hour to realize the phase transition of the color paste, and prepare a butyl acrylate dispersion containing a highly dispersible red pigment;

[0035] ...

Embodiment 2

[0040] Step 1, preparation of finely dispersed organic pigment paste with high color strength:

[0041] Add 100g of 1% sodium lauryl sulfate aqueous solution into a three-necked flask with a stirring device, then add 21g of black pigment pre-dispersed black-SMS into the aqueous solution, stir and disperse at high speed for 0.5 hours, then transfer to a grinder Grind for 5 hours to obtain a black pigment paste with a particle size of about 1 μm;

[0042] Step 2, preparation of monomers containing finely dispersed organic pigments with high color strength:

[0043] Add 110g of styrene monomer into a three-necked flask with a stirring device, add 0.66g of dodecyltrimethylammonium bromide under stirring, slowly add 1.55g of appealing black pigment paste after dissolving, and quickly Stir for 1.5 hours to realize the phase transition of the color paste, and prepare a styrene dispersion containing a highly dispersible black pigment;

[0044] Step 3, preparation of colored expandab...

Embodiment 3

[0049] Step 1, preparation of finely dispersed organic pigment paste with high color strength:

[0050] Add 100g of ethoxylated alkyl sodium sulfate aqueous solution with a concentration of 8% into a three-necked flask with a stirring device, then add 30g of phthalocyanine blue in the aqueous solution, stir and disperse at high speed for 0.8 hours, then transfer to a grinder and grind for 7.5 hour to obtain a blue pigment paste with a particle size of about 1 μm;

[0051] Step 2, preparation of monomers containing finely dispersed organic pigments with high color strength:

[0052] Add 100g of styrene monomer into a three-necked flask with a stirring device, add 0.8g of octadecyltrimethylammonium chloride under stirring, and slowly add 1.65g of the blue pigment paste after dissolving. Stir rapidly for 1.5 hours to realize the phase transition of the color paste, and prepare a styrene dispersion containing a highly dispersible blue pigment;

[0053] Step 3, preparation of col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com