Polymerization inhibitor and preparation method and application thereof

A technology of polymerization inhibitor and initiator, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

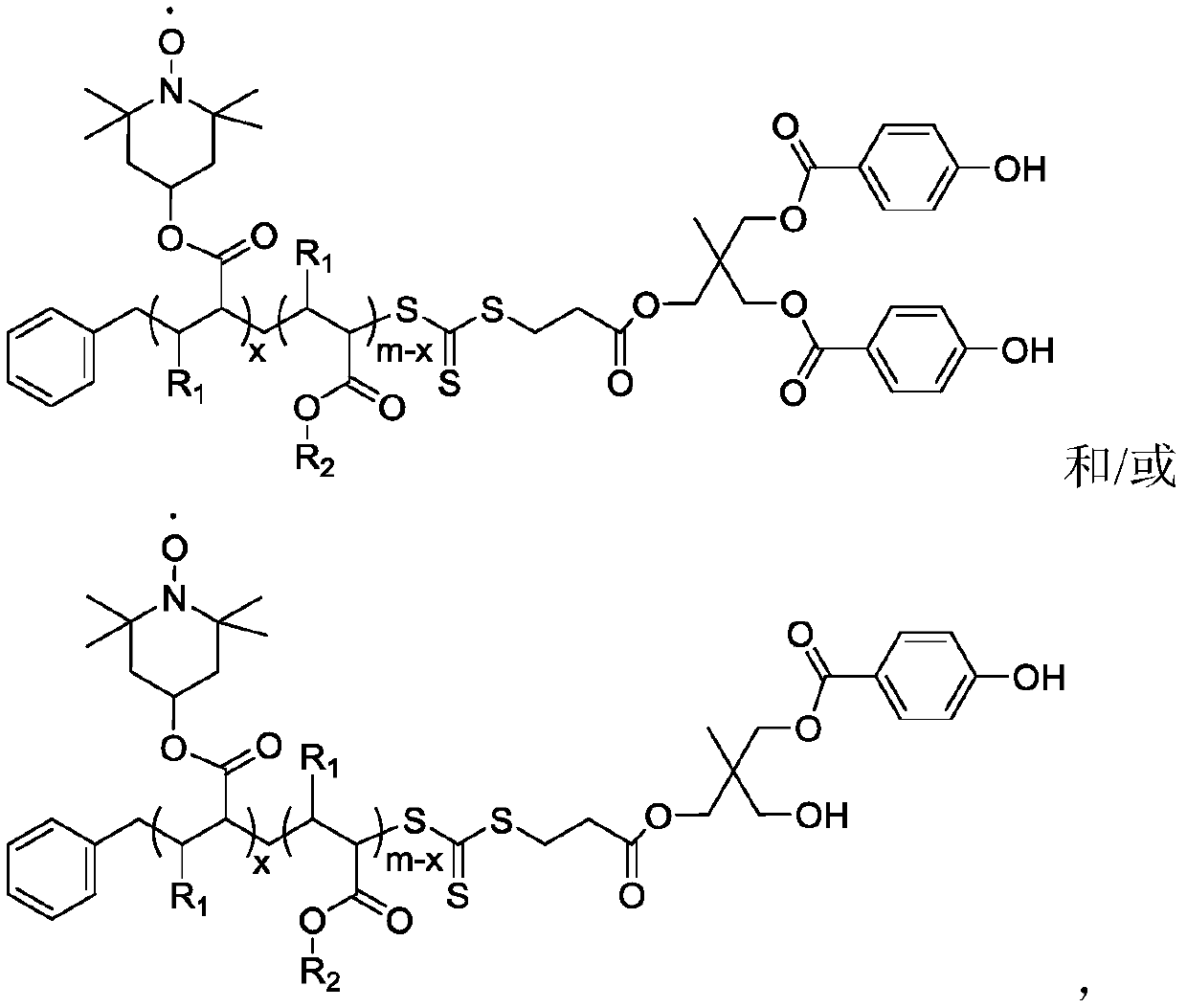

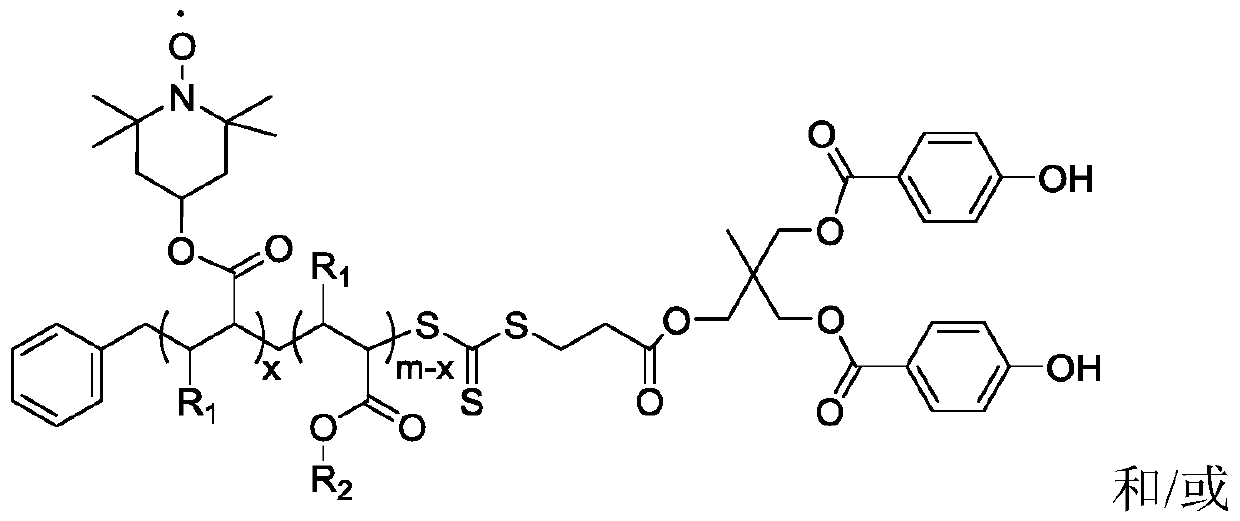

Method used

Image

Examples

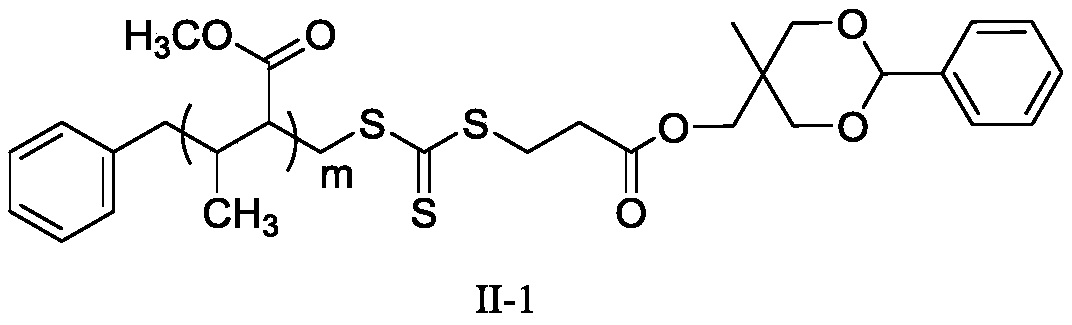

Embodiment 1

[0063] (1) Dissolve MHPD and benzyl trithiocarbonate propionic acid in dichloromethane, add catalyst 4-dimethylaminopyridine and N, N-dicyclohexylcarbodiimide, wherein benzyl trithio The molar ratio of carbonate-based propionic acid and MHPD is 1:1, the molar ratio of 4-dimethylaminopyridine and MHPD is 0.1:1, and the molar ratio of N,N-dicyclohexylcarbodiimide and MHPD is 1: 1. Under the condition of 20°C, react for 24 hours, filter after the reaction, concentrate by rotary evaporation, and precipitate with diethyl ether twice to obtain a light yellow solid, which is dried in vacuum to obtain the compound of formula I; Infrared analysis is carried out to the compound of formula I obtained, and 1732cm appears -1 ester bond peaks.

[0064] (2) Dissolve the compound of formula I and methyl methacrylate in N,N-dimethylformamide, and react under the initiation of 2,2'-azobisisobutyronitrile, wherein the initiator and formula I The molar ratio of the compound is 0.4:1, and the m...

Embodiment 2

[0073] (1) Dissolve MHPD and benzyl trithiocarbonate propionic acid in chloroform, add catalyst 4-dimethylaminopyridine and N, N-dicyclohexylcarbodiimide, wherein benzyl trithio The mol ratio of carbonate group propionic acid and MHPD is 3:1, the mol ratio of 4-dimethylaminopyridine and MHPD is 0.3:1, and the mol ratio of N,N-dicyclohexylcarbodiimide and MHPD is 3: 1. Under the condition of 50°C, react for 72 hours, filter after the reaction, concentrate by rotary evaporation, and precipitate with diethyl ether twice to obtain a light yellow solid, which is dried in vacuum to obtain the compound of formula I; Infrared analysis is carried out to the compound of formula I obtained, and 1737cm appears -1 ester bond peaks.

[0074] (2) Dissolving the compound of formula I and methyl acrylate in N,N-dimethylacetamide, and reacting under the initiation of 2,2'-azobisisoheptanonitrile, wherein the initiator and the compound of formula I The molar ratio is 0.6:1, the molar ratio of...

Embodiment 3

[0084] (1) MHPD and benzyl trithiocarbonate propionic acid are dissolved in the solvent chloroform, add catalyst 4-dimethylaminopyridine and N, N-dicyclohexylcarbodiimide, wherein benzyl trisulfide The molar ratio of carbonate group propionic acid and MHPD is 2:1, the molar ratio of 4-dimethylaminopyridine and MHPD is 0.2:1, and the molar ratio of N,N-dicyclohexylcarbodiimide and MHPD is 2 : 1, under the condition of 25°C, react for 48h, filter after the reaction, concentrate by rotary evaporation, and precipitate with solvent diethyl ether twice to obtain a light yellow solid, which is dried in vacuo to obtain the compound of formula I; Infrared analysis is carried out to the compound of formula I obtained, and 1725cm appears -1 ester bond peaks.

[0085] (2) Dissolve the compound of formula I and ethyl methacrylate in N,N-dimethylacetamide, and react under the initiation of 2,2'-azobisisobutyronitrile, wherein the initiator and formula I The molar ratio of the compound is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com