C5 diolefin auto-agglutination or copolymerization inhibition method

A diolefin and self-polymerization technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, hydrocarbons, etc., can solve problems affecting mass transfer, heat transfer, consumption of C5 materials, and equipment operating performance degradation, etc., to achieve Good polymerization inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

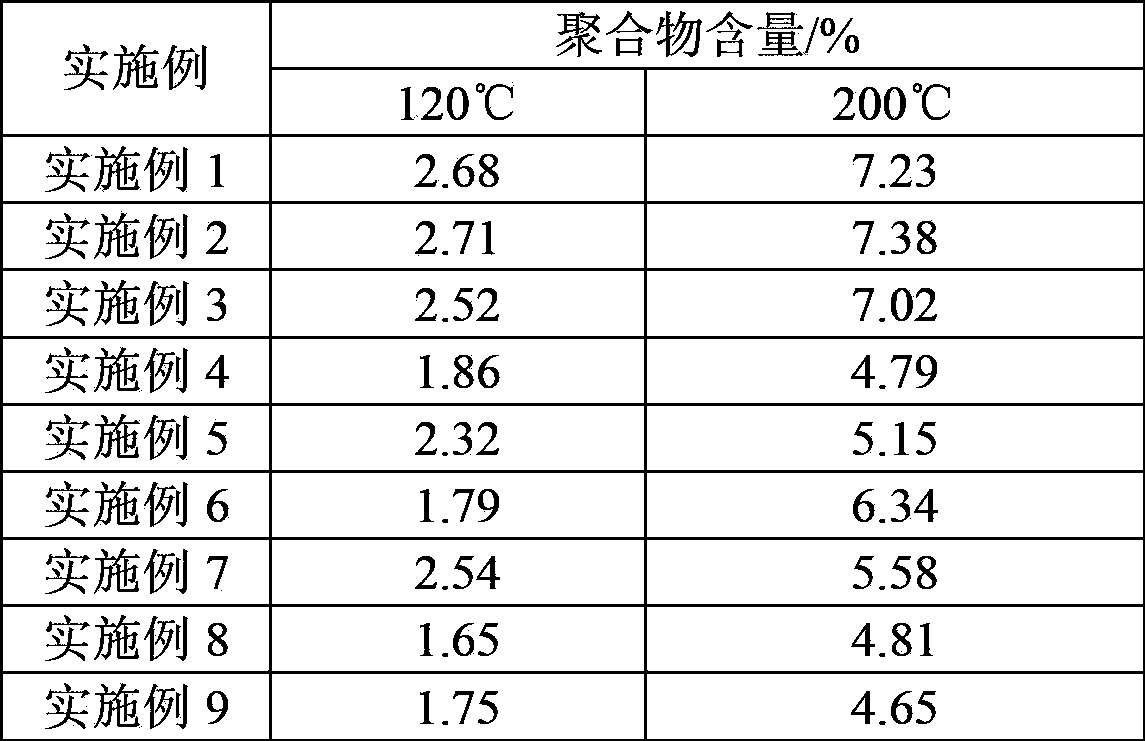

Embodiment 1~10

[0011] 1. Preparation of polymerization inhibitor

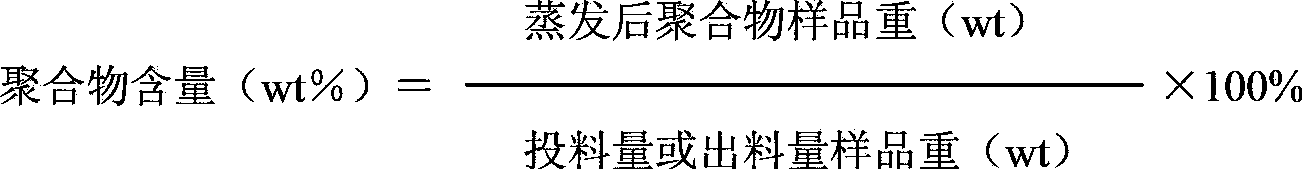

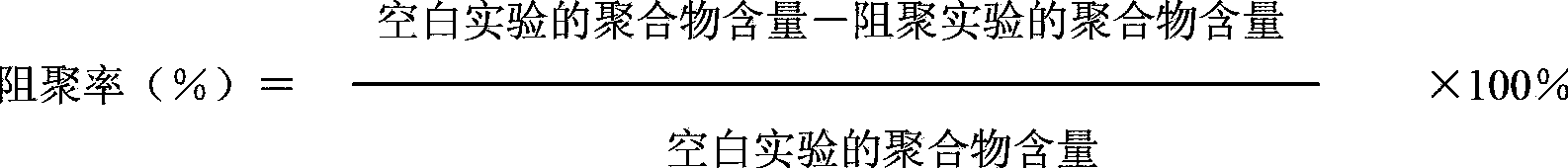

[0012] Take the required amount of component A, component B, and component C and dissolve them in a solvent to prepare a polymerization inhibitor for later use, and control the total content of component A, component B, and component C to be 25-45 wt%. The results of each embodiment are listed in Table 1.

[0013] 2. Sealing test of polymerization inhibitor

[0014] Static glass seal evaluation method

[0015] ①Use a sample injector to add the prepared polymerization inhibitor into C5 according to the required amount, divide it into two parallel samples of A and B, put them into glass tubes and seal them well, and at the same time install the blank sample without polymerization inhibitor.

[0016] ②Put it in the oven, conduct the test according to the designed temperature and time, take it out after the time is up, cool it down to room temperature, and weigh it.

[0017] ③Unscrew the sealing cap in the fume hood, and volat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com