Paste welding combination and preparation method and application thereof

A composition and paste technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of poor solderability, non-wetting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

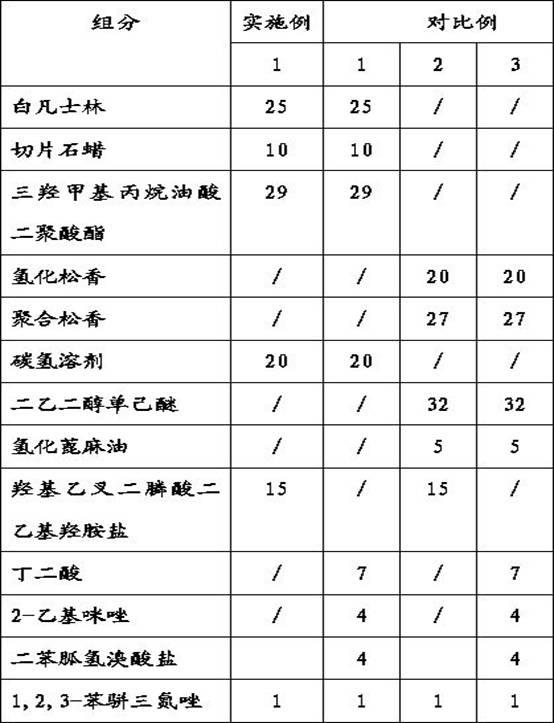

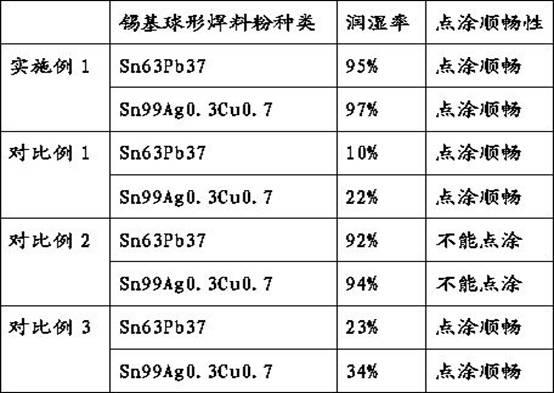

[0030] The present invention is described in detail below with the aid of examples and comparative examples, and the significant effect achieved by the present invention is illustrated through the inspection tests of the examples and comparative examples. See Table 1 for the composition and weight percentage of the paste soldering composition. The mode of carrying out the present invention is not limited to the embodiment, but merely illustrated.

[0031] Table 1 Components and content ratio of paste soldering composition

[0032]

[0033] The total amount of the above paste soldering composition is 100 g, and the unit of content of each component is g.

[0034] Embodiment 1 Preparation process:

[0035] Add white petrolatum, sliced paraffin, hydrocarbon solvent, and trimethylolpropane oleic acid dimer into the beaker in proportion, heat until clear, then slowly stir and cool. Weigh in diethylhydroxylamine salt of hydroxyethylidene diphosphonate and 1,2,3-benzotriazole,...

Embodiment 2

[0060] Weigh and mix raw materials (grams) according to the following proportions,

[0061] Prepare 100g of paste soldering composition, prepared according to the following composition and content (g) ratio:

[0062] 1. White vaseline 10, section paraffin 5, trimethylolpropane oleic acid dimer ester 30, hydrocarbon solvent 40, hydroxyethylidene diphosphonic acid diethylhydroxylamine salt 10, 1,2,3-benzotriazole 5;

[0063] 2. White vaseline 40, sliced paraffin 20, trimethylolpropane oleic acid dimer 5, hydrocarbon solvent 14.95, ethylenediamine tetramethylene phosphonic acid diethylhydroxylamine salt 20, benzimidazole 0.05;

[0064] 3. White vaseline 40, section paraffin 20, trimethylolpropane oleic acid dimer ester 30, hydrocarbon solvent 5, diethylenetriaminepentamethylene phosphonic acid diethylhydroxylamine salt 2, tolyltriazole 3 .

[0065] According to the preparation process of Example 1, a paste soldering composition and a solder paste with better comprehensive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com