Production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile

A technology of powdered nitrile rubber and its production method, which is applied in the field of production of medium nitrile micro-crosslinked powdered nitrile rubber, can solve the problems of not being able to meet the high requirements of high temperature resistant train brake shoes, and cannot guarantee the high temperature resistance of products, and achieve improvement The effect of processing stability, improving elasticity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

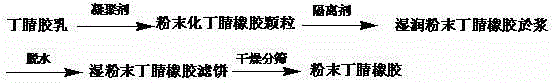

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of nitrile mucilage:

[0032] First, the polymerization kettle was evacuated, and 205 parts of soft water, 3 parts of potassium oleate, 1 part of sodium methylene di-naphthalene sulfonate as a diffusing agent, 0.2 parts of buffering agent sodium carbonate, and 0.55 parts of molecular weight regulator tert-dodecanethiol part, 0.5 part of trimethylolpropane trimethacrylate, after stirring for 10 minutes, add 29 parts of acrylonitrile, 0.2 part of initiator potassium persulfate, 0.04 part of oxygen scavenger, vacuumize with nitrogen and repeat three times, add butadiene 70.5 parts, 0.12 parts of active phase, under the reaction temperature of 25-35°C and the reaction pressure of 0.2-0.52Mpa, the reaction time is 17-20 hours, when the conversion rate reaches 60%, add the molecular weight regulator tertiary 0.55 parts of carbon mercaptan, when the conversion rate reaches 80%, add 0.40 parts of molecular weight regulator tertiary dodecyl mercaptan; when the conv...

Embodiment 2

[0041] In the synthesis step of the nitrile mortar in Example 1, add 210 parts of soft water, 3 parts of emulsifier potassium oleate, 28 parts of acrylonitrile, 71.5 parts of butadiene, 0.5 part of trimethylolpropane trimethacrylate, Other process formulas are the same as in Example 1.

[0042] The performance index of gained nitrile mortar is: PH value 10.6, Mooney viscosity (ML 1+4 100℃ ) 50, the total solids concentration is 30.8%, the gel content is 15%, and the combined acrylonitrile content is 26.5%.

[0043] After isolation into powder and dehydration and drying, the resulting product index is within the control range shown in Table 2.

Embodiment 3

[0045] In the synthesis step of nitrile mortar in Example 1, add 0.3 parts of composite terminator (a mixed solution of diethylhydroxylamine, hydroxylamine sulfate, potassium hydroxide and soft water, the mass ratio of which is 3:2:2:70) , other process formulas are with embodiment 1.

[0046] The performance index of gained nitrile mortar is: pH value 10.2, Mooney viscosity (ML 1+4 100℃ ) 54, the total solids concentration is 30.7%, the gel content is 17%, and the combined acrylonitrile content is 27.1%.

[0047] After isolation into powder and dehydration and drying, the resulting product index is within the control range shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com