Ink-jet ink and recording material

An inkjet recording material, inkjet ink technology, applied in the direction of ink, copying/marking method, application, etc., capable of solving problems such as poor light fastness, fading or discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

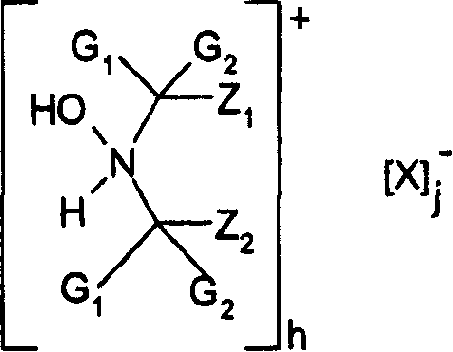

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0233] Inkjet inks were prepared by dissolving 2 g of dye in 20 g of diethylene glycol and 78 g of deionized water. The dye used was Acid Red 52. 0.15g of stabilizer was weighed into a test tube and dissolved in 2.85g of ink. Ink was filtered and transferred into empty and carefully cleaned Deskjet 510 printer (Hewlett-Packard) cartridges. Then, the stair-shaped image was printed on plain paper (sihl+eika). The resulting prints were dried under vacuum at 50 °C for 2 h and subsequently irradiated behind a 5 mm thick window glass in an Atlas Ci-35 photofading unit equipped with a xenon lamp. Operate the Atlas device at 43°C, 50% RH, no dark cycle, the light intensity is 461W / m 2 (300-800nm). The color density of each step was measured with a MacBethTR 924 densitometer before and after exposure.

[0234] The results are given below with an initial density of 1. Lower loss of density values indicates higher light fastness.

[0235] Stabilizer Low density loss (%)

[0236...

Embodiment 2

[0246] Magenta and yellow inks were drawn from a Hewlett-Packard tri-color cartridge (HP C1823D). Weigh 0.15g stabilizer into a test tube and dissolve it in 2.85g magenta or yellow ink. The resulting ink was filtered and transferred to an empty and carefully cleaned Deskjet 510 printer (Hewlett-Packard) cartridge. Then, print the ladder image on plain paper (sihl+eika) or on Hewlett-Packard Premium Photo Paper (item code C6040A). The resulting prints were dried under vacuum at 50 °C for 2 h and subsequently irradiated behind a 5 mm thick window glass in an Atlas Ci-35 photofading unit equipped with a xenon lamp. Operate the Atlas device at 43°C, 50% RH, no dark cycle, the light intensity is 461W / m 2 (300-800nm). The color density of each step was measured with a MacBeth TR 924 densitometer before and after exposure.

[0247] stabilizer

30kJ.cm -2 Density loss (%)

magenta print

on plain paper

On HP Premium paper

yellow print

on ...

Embodiment 3

[0252] Canon PR-101 sheet (Canon Japan) was post-treated with cast stabilizer in water or methanol solution using a 75 micron wire wound coating rod. After drying at room temperature, the sheet thus modified was subjected to printing of a cyan (cyan) ladder image with a Canon BJC 8200 printer. The cyan dye used was C.I. Direct Blue 199. The prints thus obtained were dried in vacuum at 50 °C for 2 h, followed by forced air flow for 4 weeks. Color density was measured with a MacBeth TR 924 densitometer before and after exposure.

[0253] Stabilizer Density loss % after 28 days

[0254] no 20

[0255] Compound A (0.5g / m 2 ) 14

[0256] Compound A (1.0g / m 2 ) 14

[0257] Compound C (0.5g / m 2 ) 14

[0258] Compound C (1.0g / m 2 ) 12

[0259] Compound D (0.5g / m 2 ) 9

[0260] Compound D (1.0g / m 2 ) 4

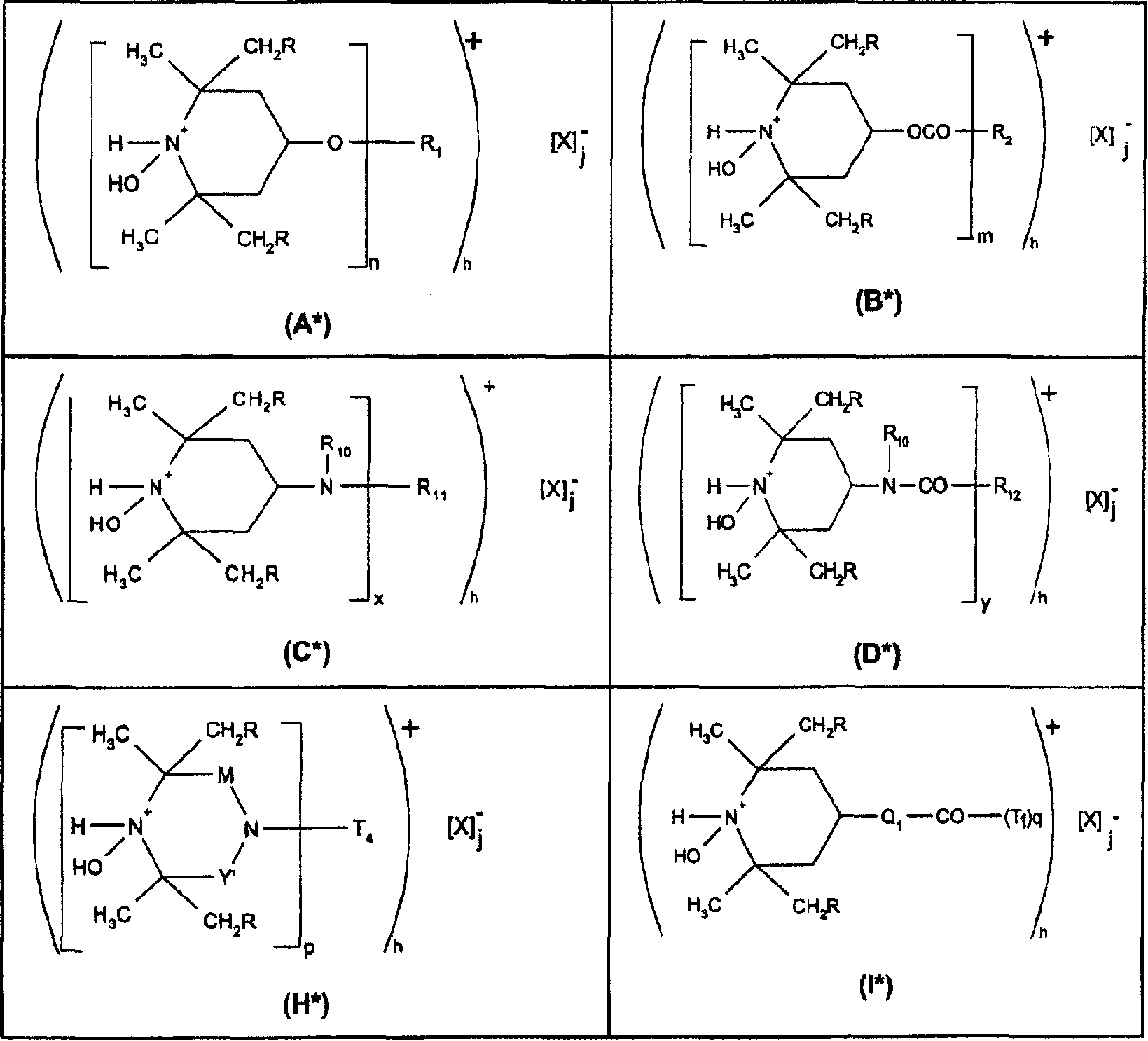

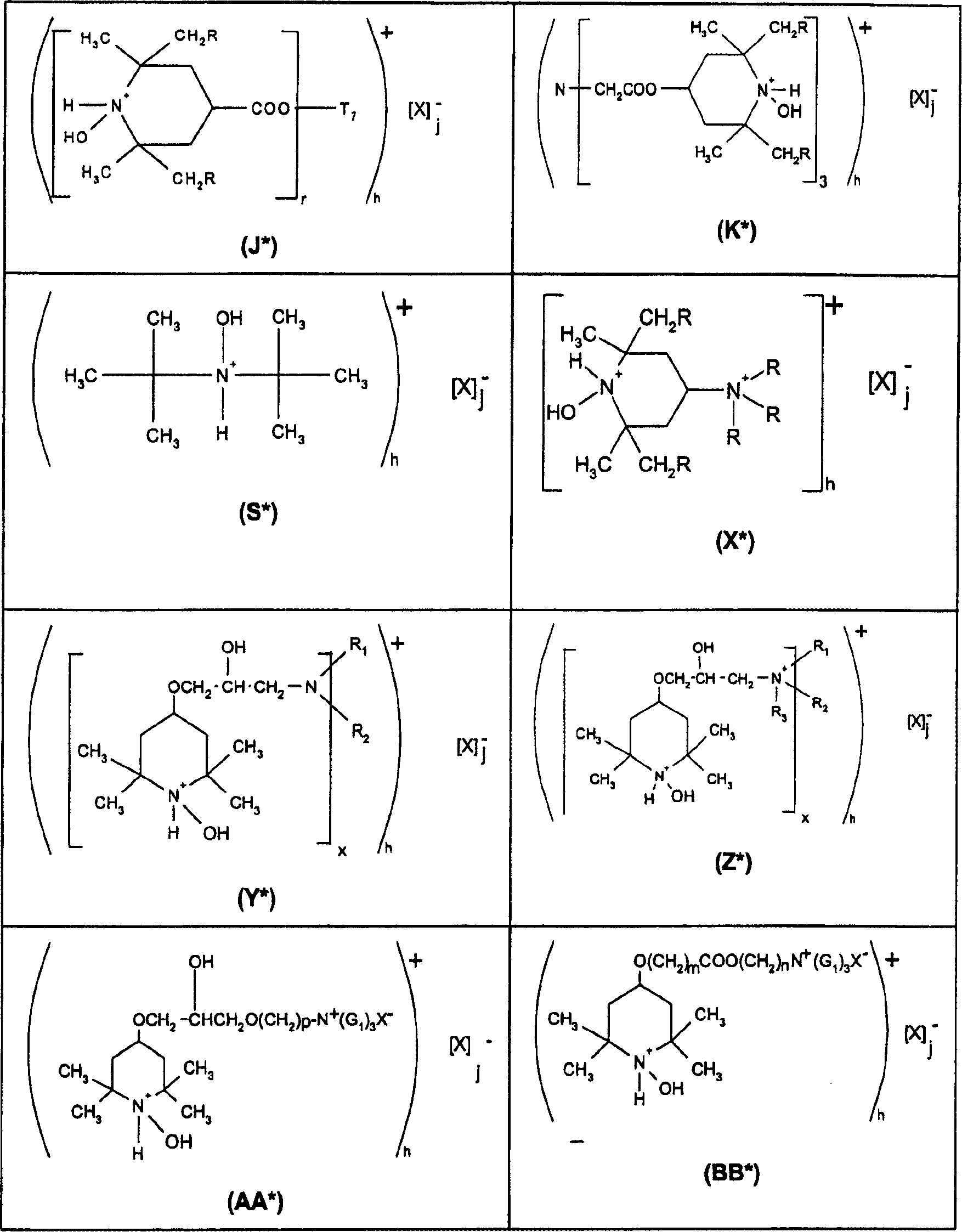

[0261] Compound A is 1-oxy-2,2,6,6-tetramethyl-4-hydroxypiperidine.

[0262] Compound C is 1-hydroxy-2,2,6,6-tetramethyl-4-hydroxypiperidinium citrate.

[0263] Comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com