Scale inhibitor for styrene rectification system

The technology of a rectification system and a scale inhibitor is applied in the field of scale inhibitor of a styrene rectification system, which can solve the problems affecting the long-term operation of the device, the rise of the tower pressure difference, and the dispersion cleaning, so as to inhibit the generation of scales, reduce the The effect of avoiding blockage of the tower and meeting the production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

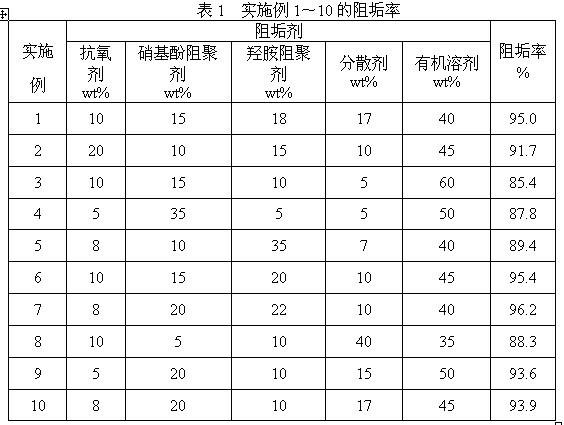

Examples

Embodiment 1

[0032] Add 100g 2,6-di-tert-butyl-4-methoxyphenol, 150g 2,6-dinitro-p-cresol, 180g isopropylhydroxylamine, 170g dienylsuccinimide and 400g ethylbenzene to the container , heat and stir, fully dissolve and mix evenly, cool to room temperature, and filter to obtain the scale inhibitor.

[0033] The antiscalant agent prepared in Example 1 was evaluated for antiscaling performance.

[0034] Evaluation of antiscalant performance

[0035] The scale inhibition performance of the scale inhibitor of the present invention is evaluated by a simulation device.

[0036] Prepare the test solution: Pour the refined styrene into the container, then add 200ppm (based on the total amount of styrene) of the scale inhibitor prepared by the above method, stir evenly, and obtain the evaluation solution.

[0037] Scale inhibition performance evaluation: put a certain amount of stainless steel filler in a self-made stainless steel simulation tower, set a liquid distributor on the top of the filler,...

Embodiment 2

[0044] Add 200g of 2,4,6-tri-tert-butylphenol, 100g of 4,6-dinitro-o-cresol, 150g of ethyl hydroxylamine, 100g of low-nitrogen polyisobutylene succinimide and 450g of toluene into the container, heat and stir, After fully dissolving and mixing evenly, cool to room temperature and filter to obtain the scale inhibitor. The scale inhibition performance evaluation method is the same as that in Example 1.

Embodiment 3

[0046] 100g2,6-di-tert-butyl-4-isobutylphenol, 150g2,6-dinitro-p-cresol, 100g N,N'-dihydroxypropyl hydroxylamine, 50g monoalkenyl succinimide and Add 600g of xylene into the container, heat and stir, fully dissolve and mix evenly, cool to room temperature, and filter to obtain the scale inhibitor. The scale inhibition performance evaluation method is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com