High-whiteness polyvinyl chloride resin and preparation method thereof

A technology of polyvinyl chloride resin and high whiteness, applied in the field of polyvinyl chloride resin, can solve the problems of low whiteness of polyvinyl chloride resin, achieve excellent thermal stability, improve stability, and run smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

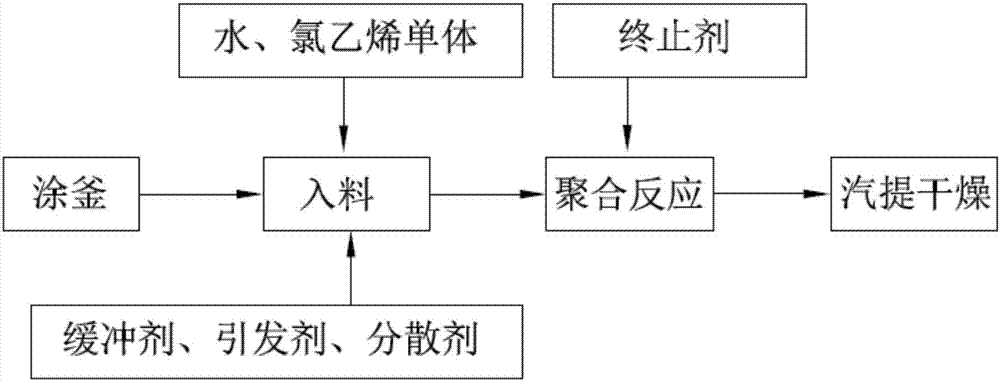

[0039] The present invention provides the following technical scheme: a preparation method of high-whiteness polyvinyl chloride resin, comprising the following steps:

[0040] Step 1: Add vinyl chloride monomer, initiator, dispersant and water into the polymerization kettle, start the polymerization reaction and time it;

[0041] Step 2: When the polymerization reaction time reaches 230-250 minutes, start to measure the pressure drop in the polymerization kettle, and when the pressure drop in the polymerization kettle reaches the set value or the polymerization reaction time reaches 440-460 minutes, add diethylhydroxylamine to compound A terminator is added to terminate the polymerization reaction to obtain a polyvinyl chloride slurry;

[0042] Step 3: stripping and drying the polyvinyl chloride slurry obtained in step 2 to obtain polyvinyl chloride resin.

[0043] The reaction mechanism of suspension polymerization is as follows:

[0044] Suspension polymerization of PVC is...

Embodiment 1

[0087] Such as figure 1 As shown, the present embodiment provides a kind of preparation method of high whiteness polyvinyl chloride resin, comprises the steps:

[0088] Step 1: Coating the Kettle

[0089] In suspension polymerization, there is a phenomenon of sticking to the kettle, which not only affects the heat transfer of the polymerization reaction, but also affects the quality of the product. The present invention uses a kettle coating agent, preferably, NOXOL WSW produced by Italian CIRS company is used to spray on the inner surface and inside of the polymerization kettle The surface of the component is used to inhibit the wall sticking during the polymerization reaction, so that the inner wall surface of the polymerization tank will not stick to the wall even after multiple continuous polymerizations.

[0090] Step 2. Feeding

[0091] Add the corresponding ratio of vinyl chloride monomer, initiator, dispersant and water into the polymerization kettle, heat to the pol...

Embodiment 2

[0117] Prepare PVC resin according to the step in embodiment 1, but proportioning is (by weight) in step 2:

[0118] Ammonium bicarbonate: 12

[0119] Vinyl chloride monomer: 23700;

[0120] Initiator: CNP (50% aqueous solution) 9, EHP (50% aqueous solution) 18;

[0121] Dispersant: HPMC (dry basis) 1.8, 88% PVA (dry basis) 4,

[0122]55% PVA (40% aqueous solution) 3, 72.5% PVA (dry basis) 13;

[0123] Water: 28500.

[0124] In step 3, when the pressure drop in the polymerization tank reaches the set value of 0.10Mpa, 25 parts by weight of diethylhydroxylamine compound terminator are added, wherein the diethylhydroxylamine compound terminator includes 82wt% diethylhydroxylamine , 8wt% stabilizer tribasic lead sulfate and 10wt% antioxidant 1076.

[0125] The pressure and temperature changes after the reaction are shown in Table 2; the whiteness and thermal stability time of the finished PVC resin are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com