Preparation method of N,N-diethyl hydroxylamine

A technology of diethylhydroxylamine and triethylamine, which is applied in the N field, can solve the problems of white oil carry-over, low production efficiency, and affecting product quality, and achieve the effects of reducing accumulation, improving production efficiency, and avoiding the use of white oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix triethylamine, 27.5% hydrogen peroxide and sodium bicarbonate in a ratio of 1:1.2:0.05, and react at 135°C with a stirring speed of 90rpm to prepare triethylamine oxide, and obtain triethylamine oxide The quality score is 82%.

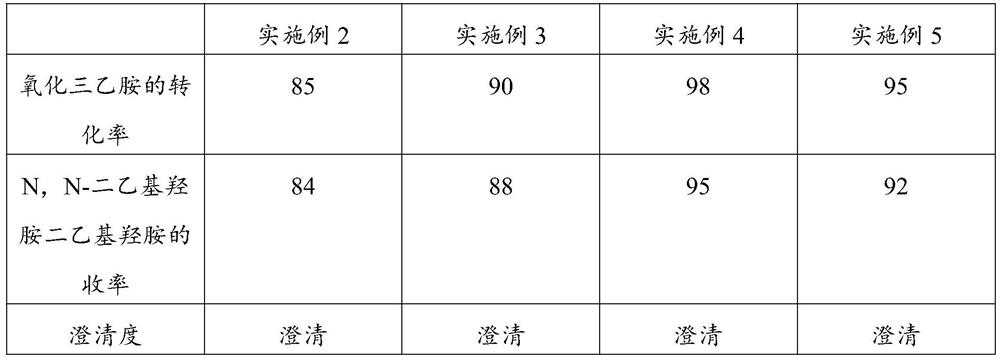

Embodiment 2

[0022] The specification of the tubular reactor used in the test is Φ8*1*1000mm, and the reaction pressure is 1atm. The reactor was heated to an internal temperature of 100°C with jacketed heat-conducting oil, and triethylamine oxide with a mass fraction of 82% was fed in at a rate of 5.74 g / min by a convection pump, and the reaction time was 60 s. After stabilizing the reaction system for 10 min, samples were taken for analysis.

Embodiment 3

[0024] The specification of the tubular reactor used in the test is Φ8*1*1000mm, and the reaction pressure is 1.5atm. The reactor was heated to an internal temperature of 200°C with jacketed heat transfer oil, and triethylamine oxide with a mass fraction of 82% was fed in at a rate of 34.5 g / min by a convection pump, and the reaction time was 360 s. After stabilizing the reaction system for 10 min, samples were taken for analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com