Byproduct comprehensive utilization method in diethyl hydroxylamine production

A technology for diethylhydroxylamine and by-products is applied in the field of comprehensive utilization of by-products in the production of diethylhydroxylamine, which can solve the problems of increased energy consumption, complex process, environmental pollution, etc., and achieves the reduction of environmental pollution, the simple production process, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

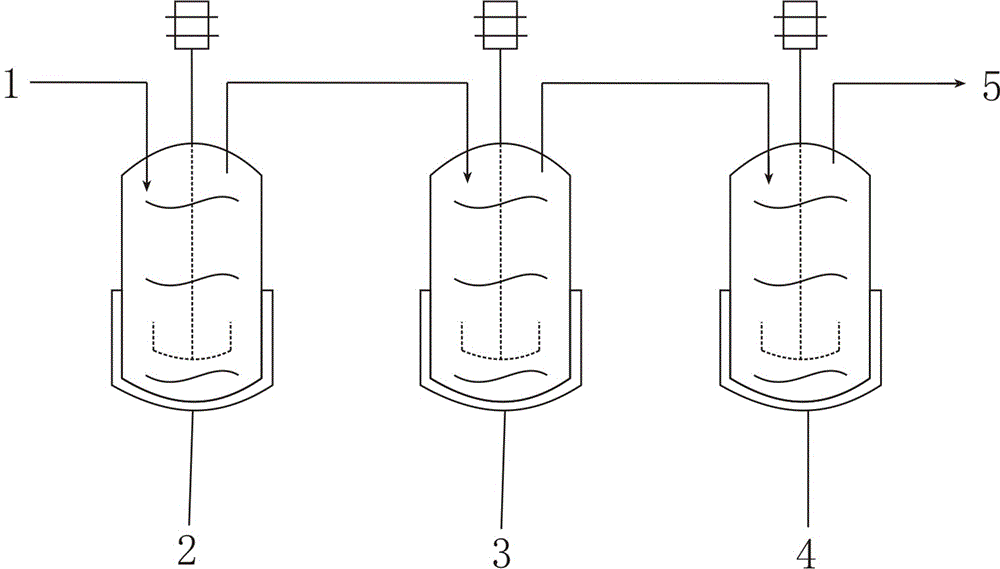

[0019] Example 1: The 2000L enamel reaction kettle I2 and the 2000L enamel reaction kettle II3 respectively contained 1800kg of bromine, and the 2000L enamel reaction kettle III4 contained 1400kg of water. Set the temperature of Reactor I2 and Reactor II3 to 25°C, and the temperature of Reactor III4 to 10°C. Vacuum tail gas ethylene 1 in the decompression cracking section of diethylhydroxylamine passes through reactor I2, reactor II3 and reactor III4 at a speed of 65Kg / h. After reacting for 32 hours, the color of the reaction solution becomes colorless, and the reaction ends, and the obtained product II Ethyl bromide is subjected to subsequent separation and storage.

Embodiment 2

[0020] Example 2: The 2000L enamel reaction kettle I2 and the 2000L enamel reaction kettle II3 respectively contained 1800kg of bromine, and the 2000L enamel reaction kettle III4 contained 1400kg of water. Set the temperature of Reactor I2 and Reactor II3 to be 45°C, and the temperature of Reactor III4 to be 15°C. Vacuum tail gas ethylene 1 in the decompression cracking section of diethylhydroxylamine passes through reactor I2, reactor II3 and reactor III4 at a speed of 65Kg / h. After 20 hours of reaction, the color of the reaction solution becomes colorless, and the reaction ends, and the obtained product II Ethyl bromide is subjected to subsequent separation and storage.

Embodiment 3

[0021] Example 3: 1500kg of bromine and 1500kg of carbon tetrachloride were contained in 2000L enamel reactor I2 and 2000L enamel reactor II3 respectively, and 1400kg of water was contained in 2000L enamel reactor III4. Set the temperature of Reactor I2 and Reactor II3 to 50°C, and the temperature of Reactor III4 to 20°C. Vacuum tail gas ethylene 1 in the decompression cracking section of diethylhydroxylamine passes through reactor I2, reactor II3 and reactor III4 at a speed of 65Kg / h. After 15 hours of reaction, the color of the reaction solution becomes colorless, and the reaction ends, and the obtained product II Ethyl bromide is subjected to subsequent separation and storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com