Lithium hexafluorophosphate synthesis technology with high reaction efficiency

一种六氟磷酸锂、合成工艺的技术,应用在锂化合物、碱金属化合物、无机化学等方向,能够解决难以实现连续化、自动化生产、产品品质一致性难以保证、五氟化磷通气管线易堵塞等问题,达到雾化效果好、占地面积小、产品质量稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

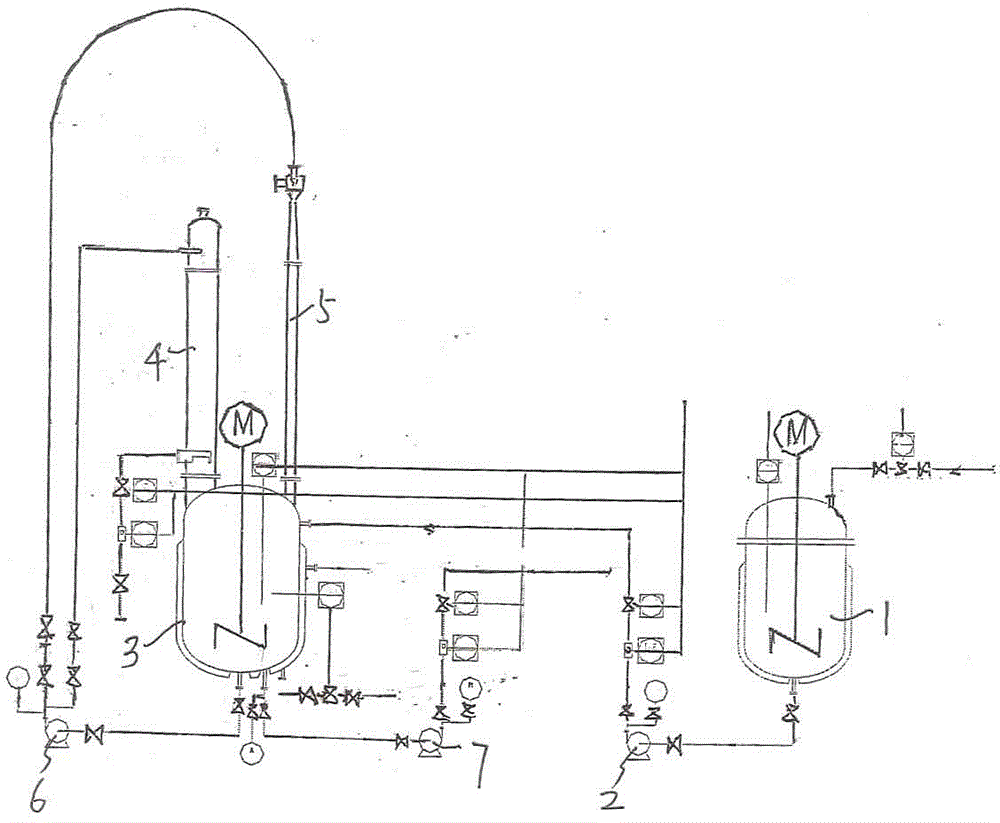

[0021] A lithium hexafluorophosphate synthesis process, the lithium fluoride anhydrous hydrogen fluoride solution from the blending tank is transferred from the intermediate tank 1 by the lithium fluoride anhydrous hydrogen fluoride solution intermediate pump 2 to the constant temperature mixing cooling tank 3, and the feed liquid in the mixing cooling tank is fed by the circulation absorption pump 6 Beat to the feed port of reaction tower 4, atomize through the non-blocking high-efficiency atomizing nozzle, and conduct sufficient heat transfer, mass transfer and synthesis reaction with phosphorus pentafluoride gas from the phosphorus pentafluoride purification section, and a small amount of unreacted The phosphorus pentafluoride gas is further reacted and absorbed by the lithium fluoride anhydrous hydrogen fluoride solution in the tail gas balance absorber 5, and the reaction solution enters the mixing cooling kettle 3, and continues to enter the tower to participate in the cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com