Method for continuous production of tetrafluorosilane by using various fluorine-containing substances, amorphous silica and sulfuric acid

A technology of amorphous silica and tetrafluorosilane, applied in chemical instruments and methods, inorganic chemistry, halogenated silanes, etc., can solve the problems of expensive metallurgical silicon and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

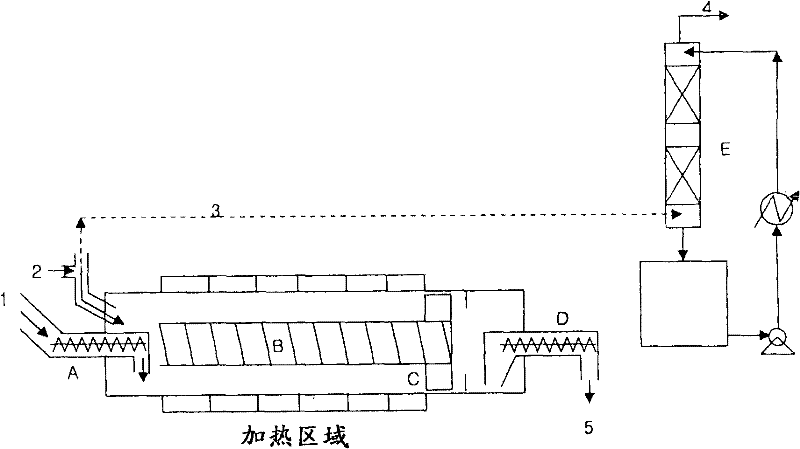

[0055] By adopting such as figure 1 The rotary kiln reactor shown is for the continuous production of tetrafluorosilane. The temperature of the reactor was directly increased by the LPG burner, and the solid raw material was dried in a calciner with an internal temperature of 350° C. for 30 minutes before using it.

[0056] Dry sodium tetrafluoroaluminate feedstock (6.87 kg / hr) and silica fume (3.66 kg / hr) with a silica content of 90% were fed into the reactor through line (1) at the same time at a concentration of 98% sulfuric acid (10.7 kg / hr) is fed through line (2).

[0057] In order to stir the raw materials smoothly, the reactor is equipped with an internal screw. Tetrafluorosilane gas is generated immediately after the reactants are fed. The gas discharged via line (3) is passed through H 2 SO 4 scrubber and subsequently collected. After the reaction was maintained for 12 hours, the analysis from H 2 SO 4 Product sampled in scrubber and final storage tanks. The...

Embodiment 2 to 5

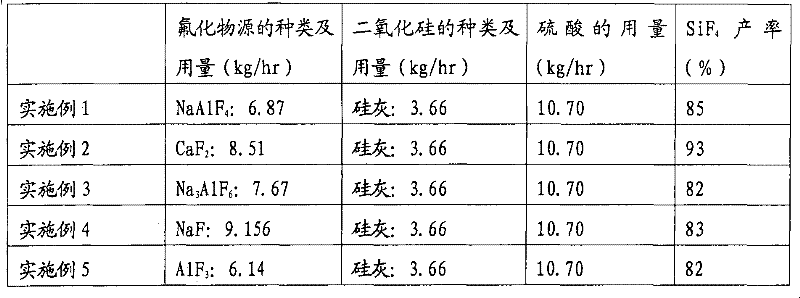

[0058][Example 2 to 5] Production of tetrafluorosilane by using silica fume

[0059] In Examples 2 to 5, the fluoride source substances were changed as shown in Table 1 below. Using SiO 2 Silica fume (3.66 kg / hr) with a content of 90% was used as a raw material for silica. Production equipment and procedures were the same as those in Example 1. After 12 hours of reaction, the generated gas was analyzed in the same manner as in Example 1. The results of the analysis are listed in Table 1 below.

[0060] [Table 1]

[0061]

Embodiment 6 to 10

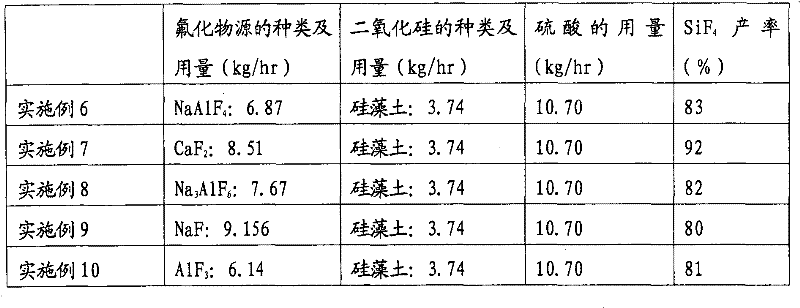

[0062] [Examples 6 to 10] Production of tetrafluorosilane by using diatomaceous earth

[0063] In Examples 6 to 10, the fluoride source substances were changed as shown in Table 2 below. Using SiO 2 Diatomaceous earth (3.74 kg / hr) with a content of 88% was used as the silica raw material. Production equipment and procedures were the same as those in Example 1. After 12 hours of reaction, the generated gas was analyzed in the same manner as in Example 1. The results of the analysis are listed in Table 2 below.

[0064] [Table 2]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com