Absorbent for flue-gas pollutants and application thereof

A technology for absorbents and pollutants, applied in gas treatment, air quality improvement, membrane technology, etc., can solve the problems of large amount of additives, high operating costs, equipment corrosion, etc., and achieve low cost, wide sources, and convenient storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

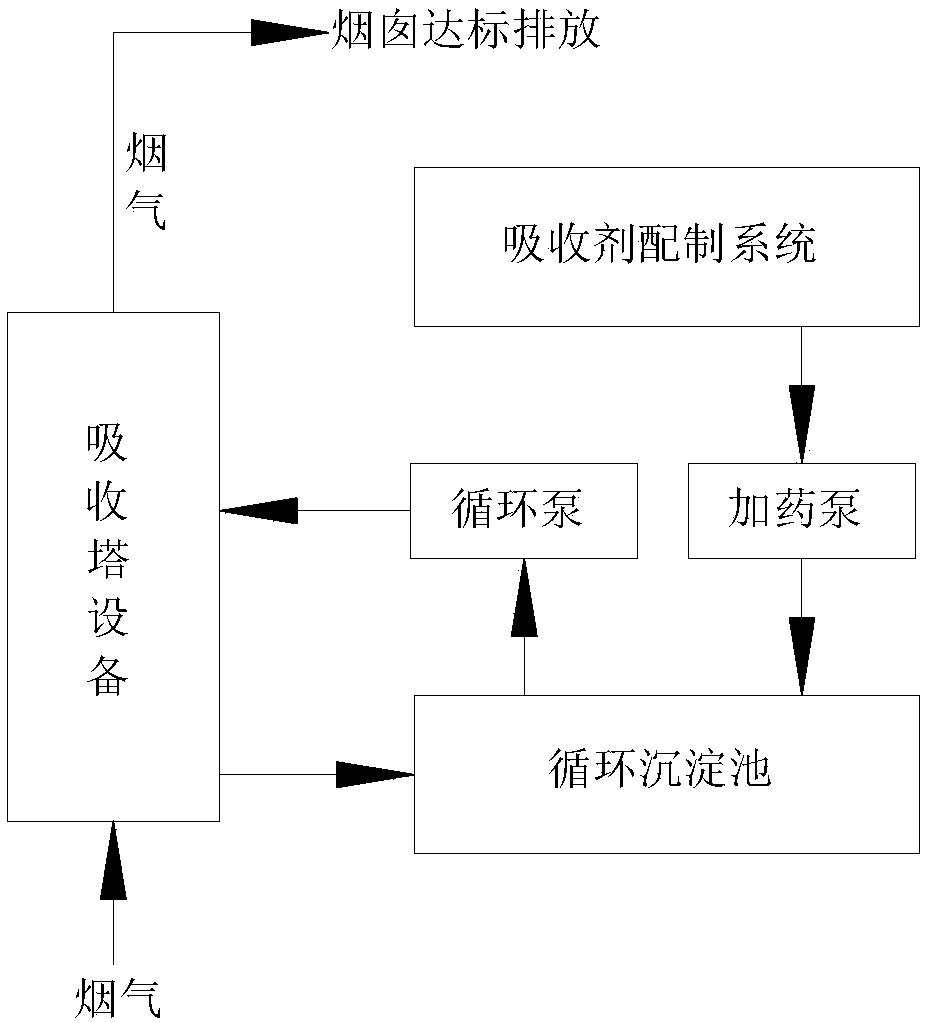

Image

Examples

Embodiment 1

[0069] Components:

[0070] The content of each component in the flue gas pollutant absorbent is calculated as a percentage of the total mass of the composite absorbent:

[0071] Component A: 30% sodium chlorite, 7% sodium hypochlorite, 5% glycine;

[0072] Component B: 45% sodium persulfate, 10% disodium hydroxyethylidene diphosphonate, 3% sodium hydroxide;

[0073] preparation:

[0074] The components A and B are mixed evenly, and then packaged separately to obtain the smoke pollutant absorbent.

[0075] application:

[0076] Dissolve 1 part of B bag of medicine in water, then slowly dissolve 1 part of A bag of medicine in B solution, stir, and prepare an absorbent solution with a mass concentration of 60%, and then prepare the absorbent solution with a mass concentration of 5%. Absorbent use liquid, and then pump the absorbent use liquid into the circulation pool for the absorption of flue gas pollutants.

[0077] Purification result:

[0078] SO 2 Concentration 3.5m...

Embodiment 2

[0087] Components:

[0088] The content of each component in the flue gas pollutant absorbent is calculated as a percentage of the total mass of the composite absorbent:

[0089] Component A: 10% potassium chlorite, 10% calcium hypochlorite, 10% sodium citrate;

[0090] Component B: 60% potassium persulfate, 5% disodium edetate, 5% potassium hydroxide;

[0091] preparation:

[0092] The components A and B are mixed evenly, and then packaged separately to obtain the smoke pollutant absorbent.

[0093] application:

[0094] Dissolve 1 part of B bag of medicament in water, then slowly dissolve 1 part of A bag of medicament in B solution, stir to prepare an absorbent solution with a mass concentration of 80%, and then prepare an absorbent solution with a mass concentration of 10% Absorbent use liquid, and then pump the absorbent use liquid into the circulation pool for the absorption of flue gas pollutants.

[0095] Purification result:

[0096] SO 2 Concentration 3.1mg / m ...

Embodiment 3

[0105] Components:

[0106] The content of each component in the flue gas pollutant absorbent is calculated as a percentage of the total mass of the composite absorbent:

[0107] Component A: 50% sodium chlorate, 1% potassium chloride, 1% sodium acetate;

[0108] Component B: 35% sodium thiosulfate, 8% disodium edetate, 5% calcium hydroxide;

[0109] preparation:

[0110] The components A and B are mixed evenly, and then packaged separately to obtain the smoke pollutant absorbent.

[0111] application:

[0112] Dissolve 1 part of B bag of medicament in water, then slowly dissolve 1 part of A bag of medicament in B solution, stir to prepare an absorbent solution with a mass concentration of 50%, and then prepare an absorbent solution with a mass concentration of 10% Absorbent use liquid, and then pump the absorbent use liquid into the circulation pool for the absorption of flue gas pollutants.

[0113] Purification result:

[0114] SO 2 Concentration 6mg / m 3 , the avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com