Method for treating chloramphenicol wastewater by electrochemical reduction oxidization and reactor of method

A technology of oxidation treatment and oxidation reaction, applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, water/sewage treatment, etc., to achieve good reaction efficiency and mineralization rate, good removal effect, and low harm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

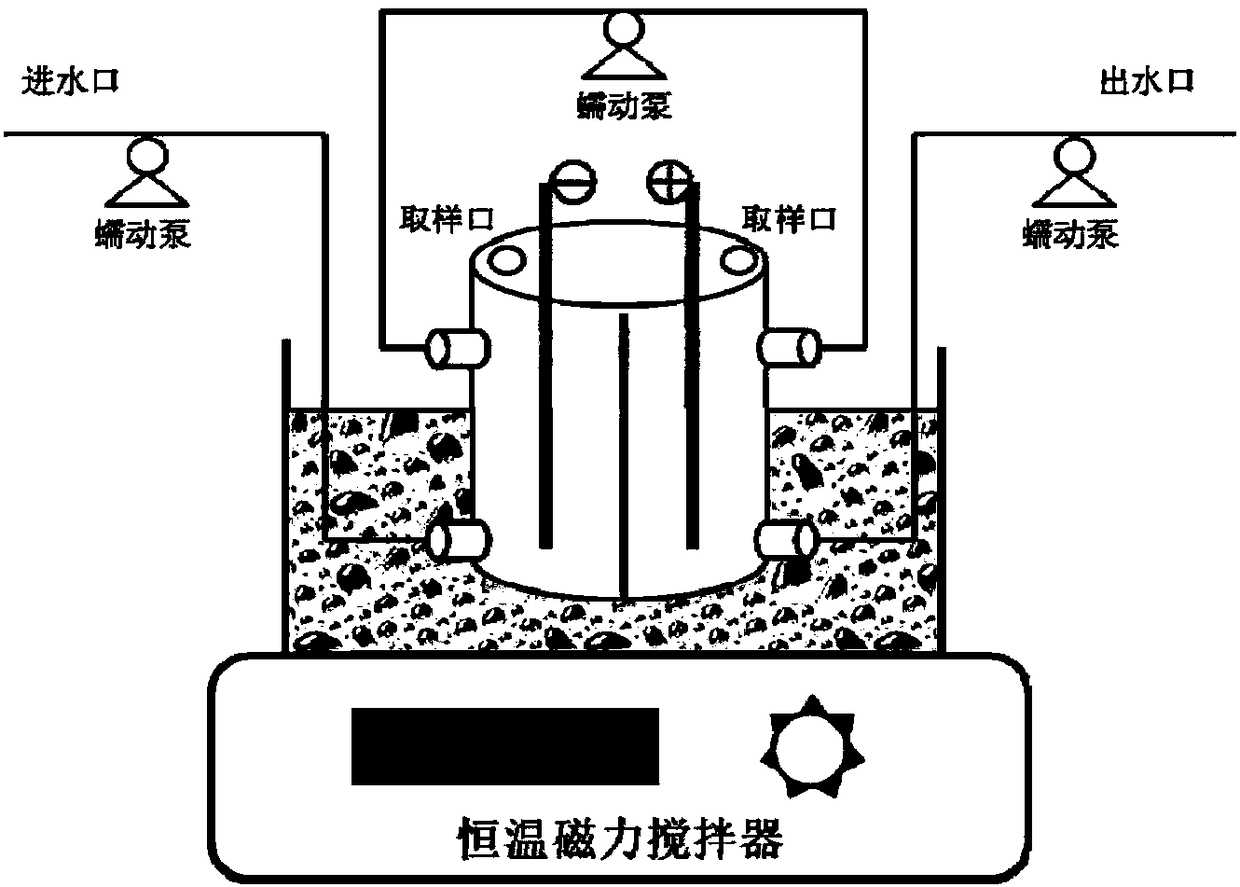

[0022] The electrochemical reduction-oxidation reactor that the present invention adopts is as figure 1 As shown, the reactor is composed of a reactor body, a magnetic stirrer with a constant temperature water bath, and an inlet and outlet water system. It is divided into a closed cathode chamber and an anode chamber, wherein the top of the cathode chamber and the anode chamber are provided with a sampling port, the cathode chamber is provided with a water supply system, and the anode chamber is provided with a water outlet system. The main body of the reactor is placed in the water bath above the magnetic stirrer which can be adjusted by the constant temperature of the water bath. The magnetic stirrer can not only control the reaction temperature, but also enhance the reaction rate of the wastewater through magnetic stirring. The cathode plate used is a titanium plate, and the anode plate is a BDD electrode. The concentration of sodium sulfate in the chloramphenicol simulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com