Novel pneumatic stirring catalytic distillation device

A catalytic rectification and pneumatic technology, applied in fractional distillation, chemical industry, distillation and separation, etc., can solve problems such as uneven mixing of gas-liquid-solid three-phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

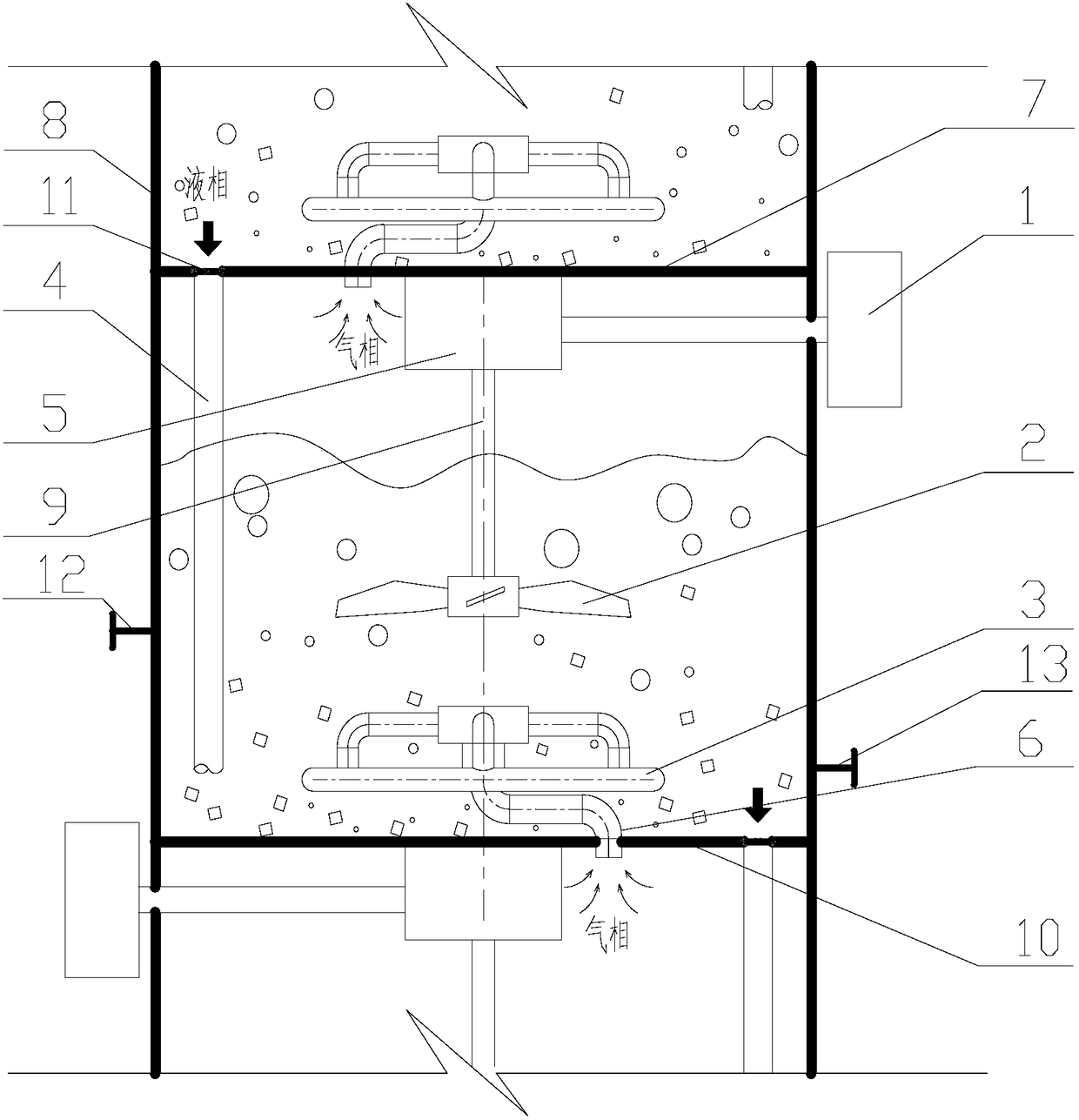

[0023] A new type of pneumatic stirring catalytic rectification device, such as figure 1 As shown, the reactor tray structure mainly includes: pneumatic agitator 1, paddle 2, gas distributor 3, downcomer 4, gear box 5, air riser 6, tray 7, shell 8, shaft 9, Tray 10, filter screen 11, catalyst replenishment port 12, catalyst outlet 13.

[0024] The light component enters the reactor from the lower tray of the reactor, and the heavy component enters the reactor from the upper tray of the reactor. A certain amount of solid particles or particulate catalysts are placed on each tray, and the reaction liquid phase from the upper tray 7 enters the space between the two trays through the downcomer 4 . The reaction gas phase from the adjacent lower tray of the tray 10 enters the space of the two trays through the gas riser 6, and is uniformly sprayed into the liquid-solid mixture of the tray 10 through the gas distributor 3 in the form of bubbles. The pneumatic agitator 1 installed o...

Embodiment 2

[0031] According to the conditions and steps described in Example 1, the distance between two adjacent trays is H, the inner diameter of the tower is D, H is 300 mm, D is 200 mm, and the gas distributor is a double-ring gas distributor. The ratio of the outer pipe diameter a of the double-ring gas distributor to the inner diameter D of the tower is 0.3, the ratio of the inner pipe diameter b to the inner diameter D of the tower is 0.2, and the center of the double-ring gas distributor coincides with the center of the tray. The opening diameter of the outer tube of the gas distributor is 2mm, the opening diameter of the inner tube is 1mm, and the openings are equally spaced and evenly distributed. The ratio of the diameter c of the riser to the inner diameter D of the tower is 0.05, the distance between the center of the inlet of the riser and the center of the tray is 0.1D, the ratio of the diameter d of the downcomer to the inner diameter D of the tower is 0.08, and the center...

Embodiment 3

[0034] According to the conditions and steps described in Example 1, the distance between two adjacent trays is H, the inner diameter of the tower is D, H is 400 mm, D is 200 mm, and the gas distributor is a double-ring gas distributor. The ratio of the outer pipe diameter a of the double-ring gas distributor to the inner diameter D of the tower is 0.5, the ratio of the inner pipe diameter b to the inner diameter D of the tower is 0.4, and the center of the double-ring gas distributor coincides with the center of the tray. The opening diameter of the outer tube of the gas distributor is 10mm, the opening diameter of the inner tube is 8mm, and the openings are equally spaced and evenly distributed. The ratio of the diameter c of the riser to the inner diameter D of the tower is 0.1, the distance between the center of the inlet of the riser and the center of the tray is 0.2D, the ratio of the diameter d of the downcomer to the inner diameter D of the tower is 0.25, and the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com