Epoxy plant oil modified phenol-formaldehyde resin, its preparation method and application

A technology of epoxidized vegetable oil and phenolic resin, used in circuit substrate materials, printed circuit components, etc., can solve the problems of poor stability and safety in the synthesis process, low resin crosslinking density, low product quality, etc., and achieve excellent electrical insulation. Performance, Low Water Absorption, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

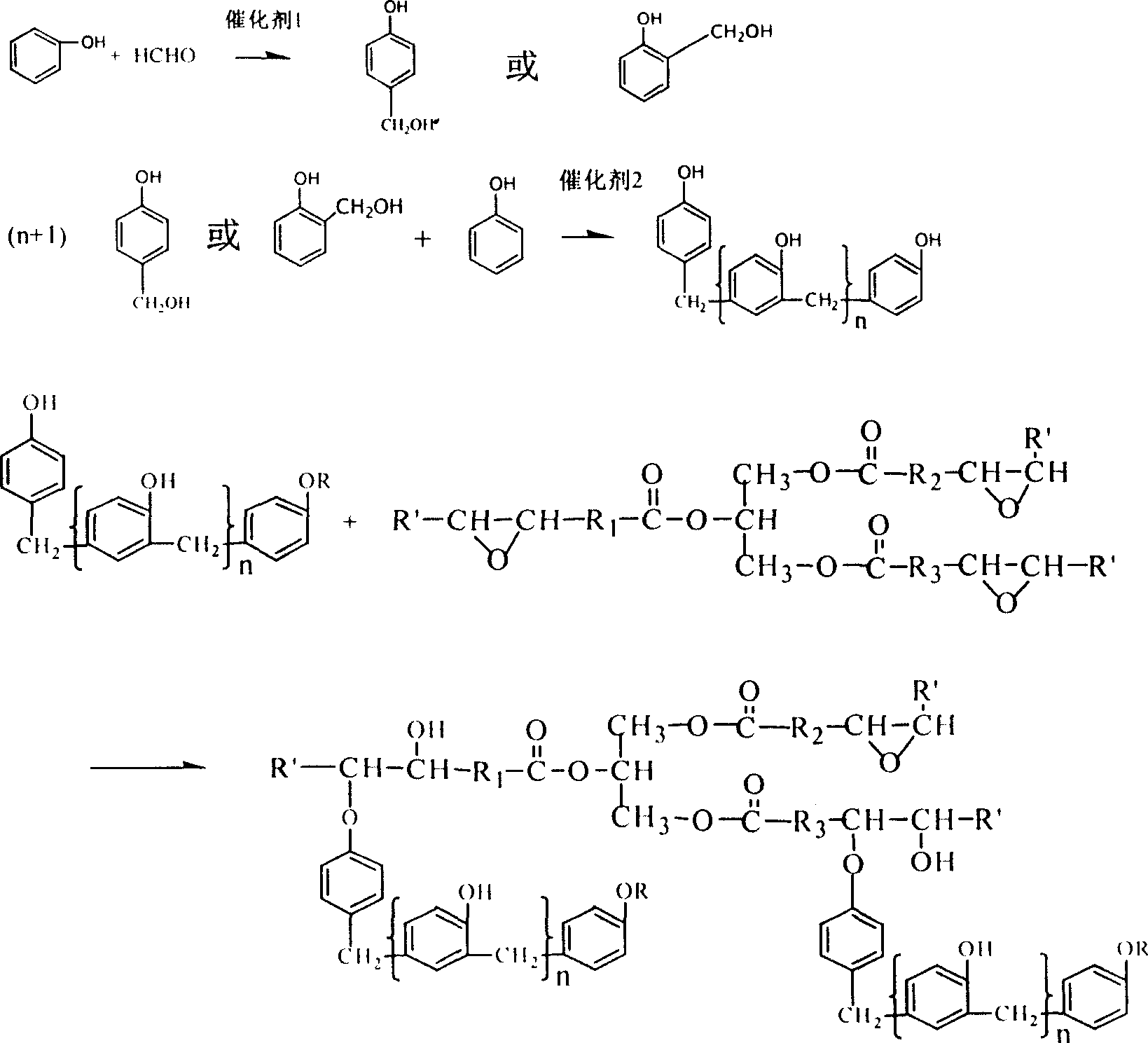

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of epoxy vegetable oil modified phenolic resin, its step comprises:

[0036] (1) Phenol: formaldehyde solution (mass ratio concentration 37%): non-toxic acidic catalyst (a mixture of industrial grade adipic acid and industrial grade hydrochloric acid, mass ratio 5: 1) is added to the reactor in a mass ratio of 100: 50: 1.5 , control the reaction temperature to 80°C, heat and stir the reaction for 3 hours, and lower it to room temperature to obtain crude phenolic resin;

[0037] (2) Dehydration treatment: the crude phenolic resin obtained in step (1) is transferred to a vacuum still, and at a temperature of 70° C., vacuum distillation removes moisture under the conditions of a vacuum of 0.09 MPa until the crude phenolic resin water content Below 0.5%, drop to room temperature to obtain phenolic resin;

[0038](3) Epoxidized soybean oil modification treatment: 100g of phenolic resin obtained in step (2), weakly basic catalyst (the mixture of ...

Embodiment 2

[0040] A kind of preparation method of epoxy vegetable oil modified phenolic resin, its step comprises:

[0041] (1) Add phenol: formaldehyde solution (mass ratio concentration 37%): non-toxic acidic catalyst (industrial grade concentrated hydrochloric acid) into the reactor at a mass ratio of 100:20:0.05, control the reaction temperature to 100°C, and keep stirring for 5 hours , down to room temperature to obtain crude phenolic resin;

[0042] (2) Dehydration treatment: the crude phenolic resin obtained in step (1) is transferred to a vacuum still, and at a temperature of 100° C., vacuum distillation removes moisture under the conditions of a vacuum of 0.03 MPa until the crude phenolic resin water content Below 0.5%, drop to room temperature to obtain phenolic resin;

[0043] (3) Epoxidized soybean oil modification treatment: add 100 g of phenolic resin obtained in step (2) and 0.5 g of weakly basic catalyst (technical grade triethylamine) into the reactor, control the react...

Embodiment 3

[0045] A kind of preparation method of epoxy vegetable oil modified phenolic resin, its step comprises:

[0046] (1) Phenol: formaldehyde solution (mass ratio concentration 15%): non-toxic acidic catalyst (a mixture of industrial grade acetic acid and industrial grade benzenesulfonic acid, mass ratio 7: 1) is added to the reactor in a mass ratio of 100: 200: 10 , control the reaction temperature to 40°C, heat and stir the reaction for 8 hours, and cool down to room temperature to obtain crude phenolic resin;

[0047] (2) Dehydration treatment: the crude phenolic resin obtained in step (1) is transferred to a vacuum distillation still, and the temperature is 60° C., and the decompression distillation removes moisture under the condition of a vacuum of 0.09 MPa until the crude phenolic resin water content Below 0.5%, drop to room temperature to obtain phenolic resin;

[0048] (3) Epoxidized soybean oil modification treatment: 100 g of phenolic resin obtained in step (2), weakly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com