Preparation method for uvioresistant and cationic dyeable polyester chip

A polyester chip, anti-ultraviolet technology, applied in the direction of one-component polyester rayon, etc., to achieve good spinnability, improved anti-aging performance, reasonable and effective anti-violet mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

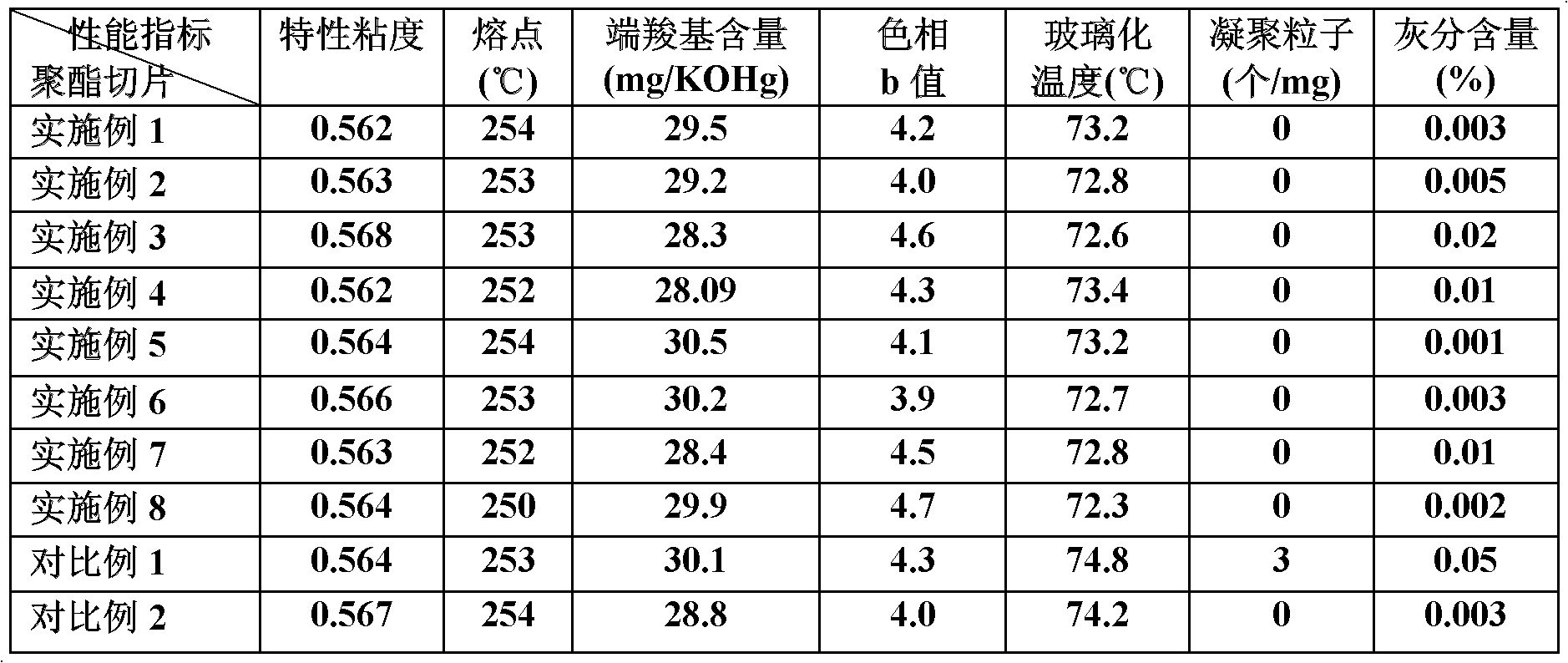

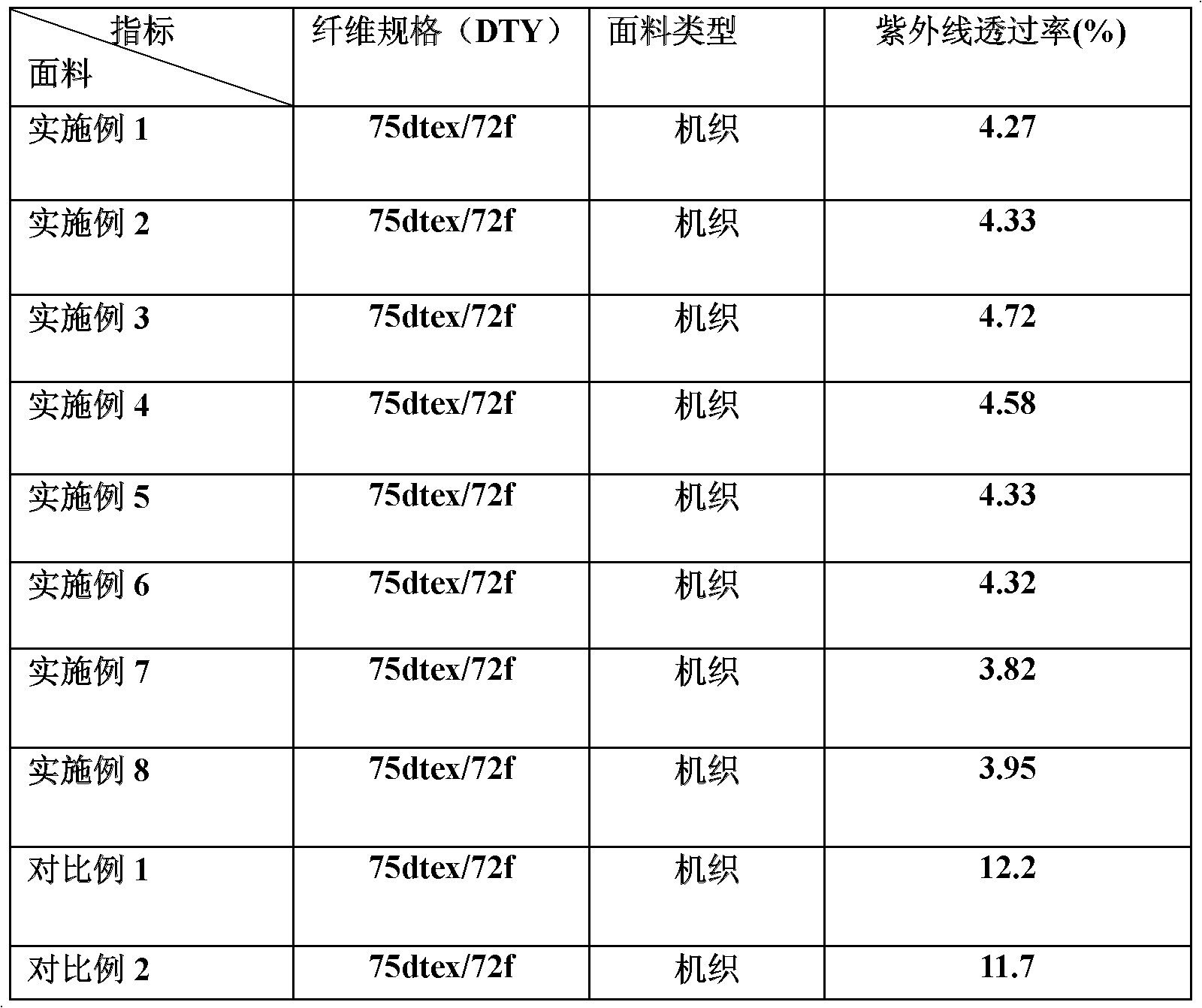

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing an anti-ultraviolet, cationic dyeable polyester chip, which comprises the following steps:

[0026] (1), esterification reaction process: take 18kg of purified terephthalic acid (PTA), 7.05kg of ethylene glycol (EG), add 70 liters of polyester experimental equipment, after stirring evenly, start to heat up and pressurize to 0.3Mpa, Esterification is carried out, and the esterification temperature is controlled at 255-260°C. After the esterification is completed, the water is discharged, and the normal pressure is returned to complete the reaction.

[0027] (2), transesterification reaction process: After the primary esterification is completed, add ethylene glycol to cool down and depolymerize, control the temperature at 220-245°C, and take 0.4-1.0 hours, then add 1400g of three-monomer solution, stir evenly, and heat up to At 255°C, a secondary transesterification reaction is carried out to complete the transesterificatio...

Embodiment 2

[0030] This embodiment provides a method for preparing an anti-ultraviolet, cationic dyeable polyester chip, which comprises the following steps:

[0031] (1), esterification reaction process: take 18kg of purified terephthalic acid (PTA), 7.05kg of ethylene glycol (EG), add 70 liters of polyester experimental equipment, after stirring evenly, start to heat up and pressurize to 0.3Mpa, Esterification is carried out, and the esterification temperature is controlled at 255-260°C. After the esterification is completed, the water is discharged, and the normal pressure is returned to complete the reaction.

[0032] (2), transesterification reaction process: After the primary esterification is completed, add ethylene glycol to cool down and depolymerize, control the temperature at 220-245°C, and take 0.4-1.0 hours, then add 1400g of three-monomer solution, stir evenly, and heat up to At 255°C, a secondary transesterification reaction is carried out to complete the transesterificatio...

Embodiment 3

[0035] This embodiment provides a method for preparing an anti-ultraviolet, cationic dyeable polyester chip, which comprises the following steps:

[0036] (1), esterification reaction process: take 18kg of purified terephthalic acid (PTA), 7.05kg of ethylene glycol (EG), add 70 liters of polyester experimental equipment, after stirring evenly, start to heat up and pressurize to 0.3Mpa, Esterification is carried out, and the esterification temperature is controlled at 255-260°C. After the esterification is completed, the water is discharged, and the normal pressure is returned to complete the reaction.

[0037] (2), transesterification reaction process: After the primary esterification is completed, add ethylene glycol to cool down and depolymerize, control the temperature at 220-245°C, and take 0.4-1.0 hours, then add 1400g of three-monomer solution, stir evenly, and heat up to At 255°C, a secondary transesterification reaction is carried out to complete the transesterificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com