Method for preparing dispersive type carbon black adopting surface graft modification method

A surface graft modification and dispersion technology, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of narrow application range, cumbersome steps, and many steps, and achieves wide application range and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

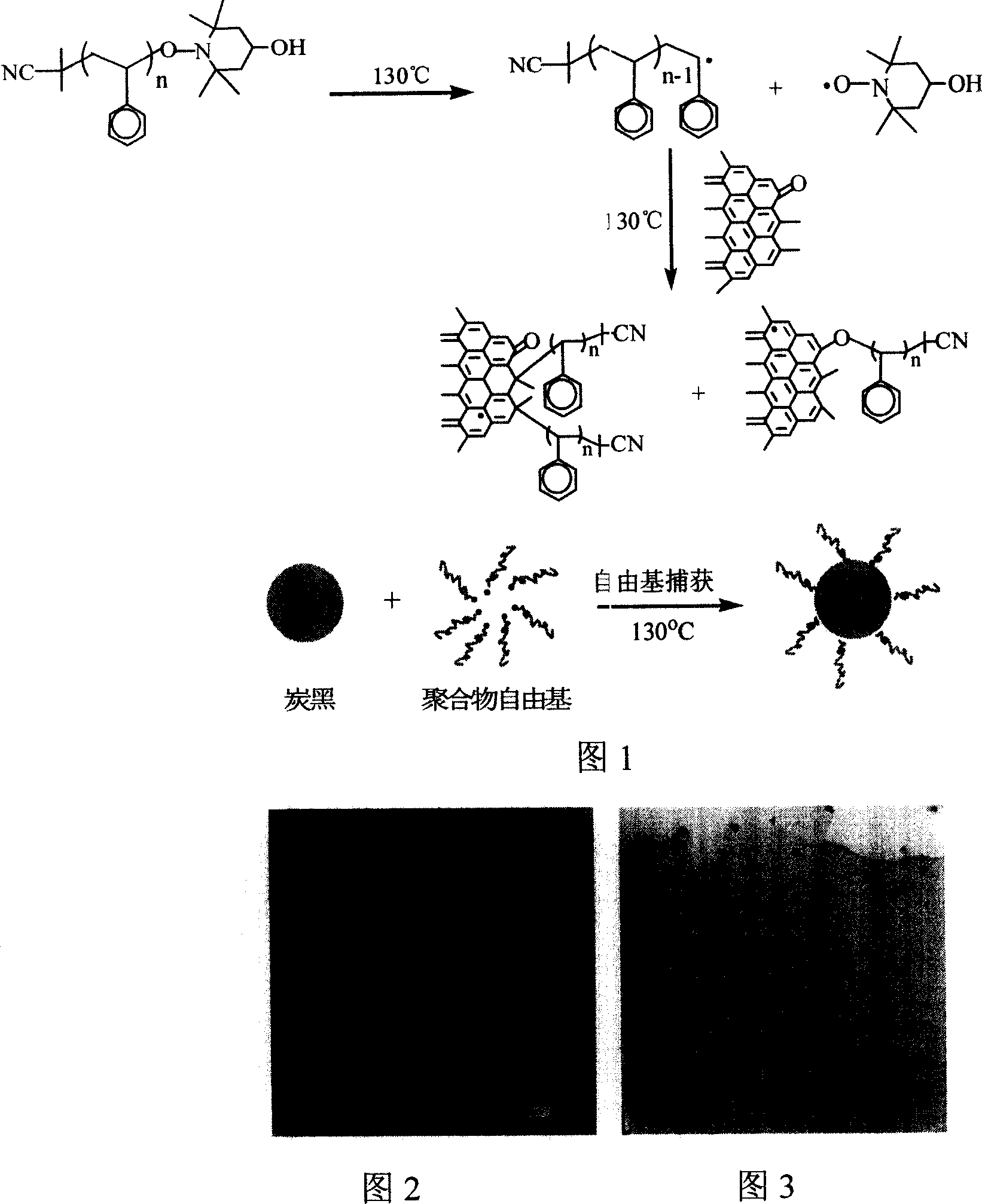

Method used

Image

Examples

Embodiment 1

[0037] 1) Add 10mL of styrene (87.4mmol), 98.5mg of azobisisobutyronitrile (0.6mmol) and 103.8mg of HTEMPO (0.6mmol) into a 50ml three-necked flask. After deoxygenation, the reaction system is protected by argon and Under stirring, use an oil bath to heat, first react at 95°C for 1 hour, and then heat to 125°C to continue the reaction for 7 hours. After the reaction, the product is precipitated with ethanol, and finally dried in vacuum to obtain polystyrene with HTEMPO end groups.

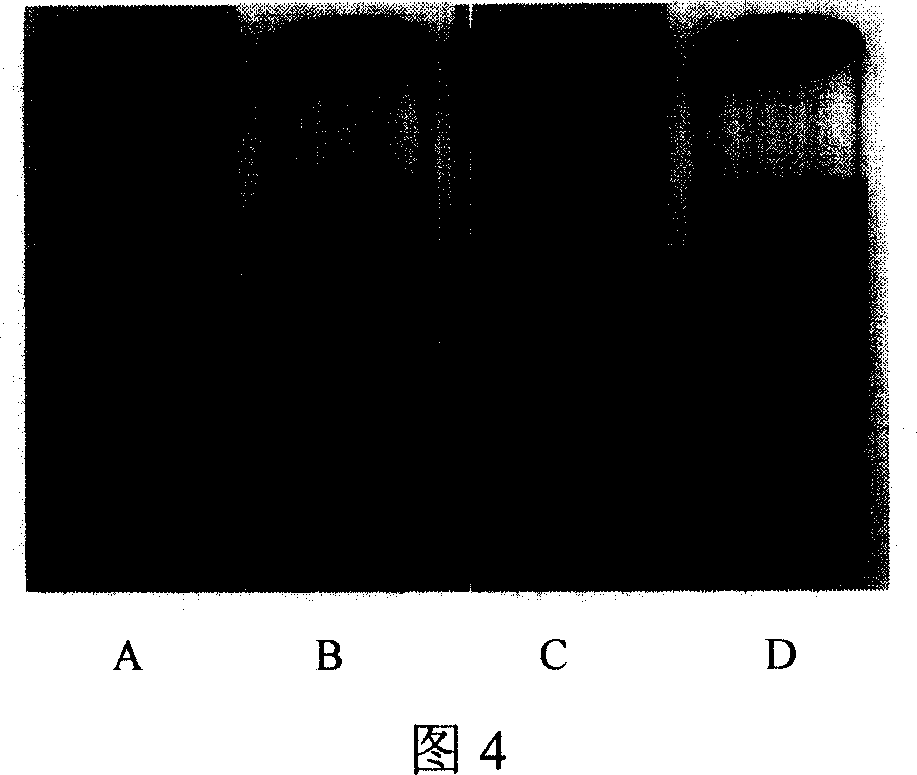

[0038] 2) Add 50mg of carbon black, 5ml of N,N-dimethylformamide and 0.20g of polystyrene with HTEMPO end groups prepared into a 25ml two-necked flask. After deoxygenation, the reaction system is protected by argon. Under stirring, use an oil bath to heat and raise the temperature to 130°C for 24 hours. After the reaction, the obtained product is washed with tetrahydrofuran under ultrasound, and then centrifuged; the ultrasonic washing-centrifugal separation process is repeated 6 times, and finally the...

Embodiment 2

[0040] 1) Put 5mL styrene (43.7mmol), 0.4285g maleic anhydride (4.37mmol), 40mg benzoyl peroxide (0.165mmol) and 51.2mg HTEMPO (0.297mmol) into a 50ml three-necked flask, the reaction system After deoxygenation, under argon protection and stirring, use oil bath heating, first react at 100°C for 1 hour, and then heat to 125°C to continue the reaction for 7 hours. After the reaction, the product is precipitated with ethanol and finally dried in vacuum to obtain poly(styrene-co-maleic anhydride) with HTEMPO end groups.

[0041] 2) Add 50mg of carbon black, 5ml of N,N-dimethylformamide and 0.20g of poly(styrene-co-maleic anhydride) with HTEMPO end groups prepared into a 25ml two-necked flask, the reaction system is removed After oxygen, under argon protection and stirring, use an oil bath to heat, and raise the temperature to 130°C for 24 hours. After the reaction, the obtained product was washed with tetrahydrofuran under ultrasound, and then centrifuged; this ultrasound washing-cent...

Embodiment 3

[0043]1) Add 3mL 4-vinylpyridine (28.5mmol), 13.4mg benzoyl peroxide (0.0553mmol) and 12.4mg HTEMPO (0.0721mmol) into a 50ml three-necked flask. After deoxygenation, the reaction system is heated in argon. Under protection and stirring, use oil bath heating, first react at 100°C for 1 hour, and then heat to 125°C to continue the reaction for 7 hours. After the completion of the reaction, the product was precipitated with ether and finally dried under vacuum to obtain poly(4-vinylpyridine) with HTEMPO end groups.

[0044] 2) Add 50mg of carbon black, 5ml of N,N-dimethylformamide and 0.75g of poly(4-vinylpyridine) with HTEMPO end groups into a 25ml two-necked flask. After deoxygenation, the reaction system is protected under argon. Under stirring, use an oil bath to heat, and raise the temperature to 130°C to react for 12 hours. After the reaction, the obtained product was washed with N,N-dimethylformamide under ultrasound, and then centrifuged; this ultrasound washing-centrifugal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com