Preparation method of neopentyl glycol dimethacrylate

A technology of neopentyl glycol dimethacrylate and methyl methacrylate is applied in the preparation of carboxylate, the preparation of organic compounds, the preparation of ester groups and hydroxyl groups, etc., which can solve the problem of low product conversion rate and catalyst price. Expensive, high production costs, to achieve the effect of shortening the reaction time, reducing the reaction cost and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

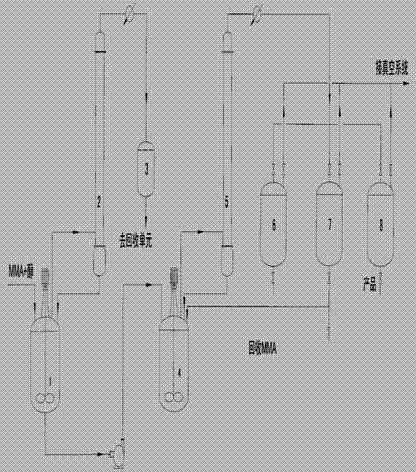

Image

Examples

Embodiment 1

[0036] 1200g of methyl methacrylate and 250g of neopentyl glycol were added into the reactor 1, 14.5g of sodium thiocyanate was added as a catalyst, and 2g of tetramethylpiperidinyl nitroxide radical phosphite was added as a polymerization inhibitor.

[0037] Start stirring, heat up, and when the temperature in the reactor 1 rises to 90-98°C, the top of the tower starts to discharge, full reflux, and when the temperature of the top of the tower is stable at 62-64°C, start the top reflux ratio system, and the reflux ratio is 6 : 1~6:2, by adjusting the reflux ratio, the temperature at the top of the tower is stabilized at 62~70°C. When the temperature of the kettle rises to 110~130°C, and the temperature at the top of the tower rises significantly, stop heating, cool down, and take samples for analysis .

[0038] The product in the still is 884.5g in total, and its composition is (measured by gas chromatography):

[0039] Methanol 0.05%

[0040] Methyl methacrylate 83.05%

...

Embodiment 2

[0045] 1200g of methyl methacrylate and 250g of neopentyl glycol were added into reactor 1, 14.5g of potassium carbonate was added as a catalyst, and 2g of tetramethylpiperidinyl nitroxide radical phosphite was added as a polymerization inhibitor.

[0046] Start stirring, heat up, and when the temperature in the reactor 1 rises to 90-98°C, the top of the tower starts to discharge, full reflux, and when the temperature of the top of the tower is stable at 62-64°C, start the top reflux ratio system, and the reflux ratio is 6 : 1~6:2, by adjusting the reflux ratio, the temperature at the top of the tower is stabilized at 62~70°C. When the temperature of the kettle rises to 110~130°C, and the temperature at the top of the tower rises significantly, stop heating, cool down, and take samples for analysis .

[0047] The product in the still is 1262g in total, and its composition is (measured by gas chromatography):

[0048] Methanol 0.04%

[0049] Methyl methacrylate 56.9%

[0050...

Embodiment 3

[0055] Add 1200kg methyl methacrylate and 250kg neopentyl glycol to reaction kettle 1, add 14.5kg sodium thiocyanate and potassium carbonate (mixing ratio 1:3) as catalyst, add 2kg tetramethylpiperidine nitrogen oxygen free Triphosphite as a polymerization inhibitor.

[0056] Start stirring, heat up, and when the temperature in the reactor 1 rises to 90-98°C, the top of the tower starts to discharge, full reflux, and when the temperature of the top of the tower is stable at 62-64°C, start the top reflux ratio system, and the reflux ratio is 6 : 1~6:2, by adjusting the reflux ratio, the temperature at the top of the tower is stabilized at 62~70°C. When the temperature of the kettle rises to 110~130°C, and the temperature at the top of the tower rises significantly, stop heating, cool down, and take samples for analysis .

[0057] The total product in the kettle is 1263kg, and its composition is (measured by gas chromatography):

[0058] Methanol 0.05%

[0059] Methyl methacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com