Patents

Literature

175 results about "Nitroso Compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

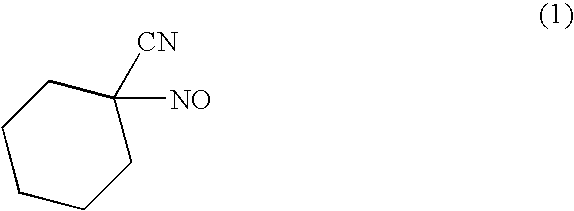

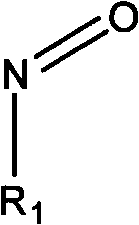

Organic compounds containing the nitroso (-N=O) group attached to an organic moiety.

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

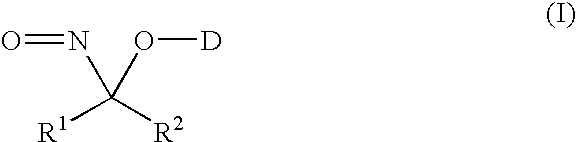

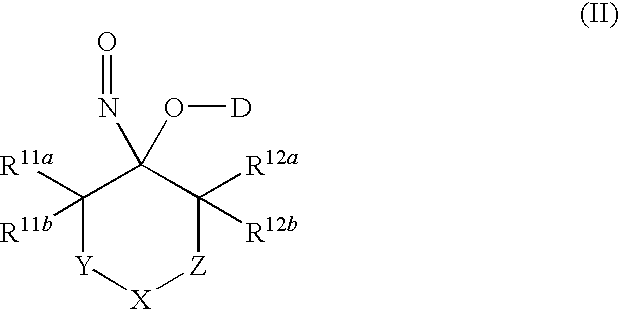

Nitroso compounds as nitroxyl donors and methods of use thereof

The invention relates to nitroso derivatives including carboxylic acid and phosphoric acid esters of hydroxy nitroso compounds that donate nitroxyl (HNO) under physiological conditions. The compounds and compositions of the invention are useful in treating and / or preventing the onset and / or development of diseases or conditions that are responsive to nitroxyl therapy, including heart failure, ischemia / reperfusion injury and cancer.

Owner:CARDIOXYL PHARMA

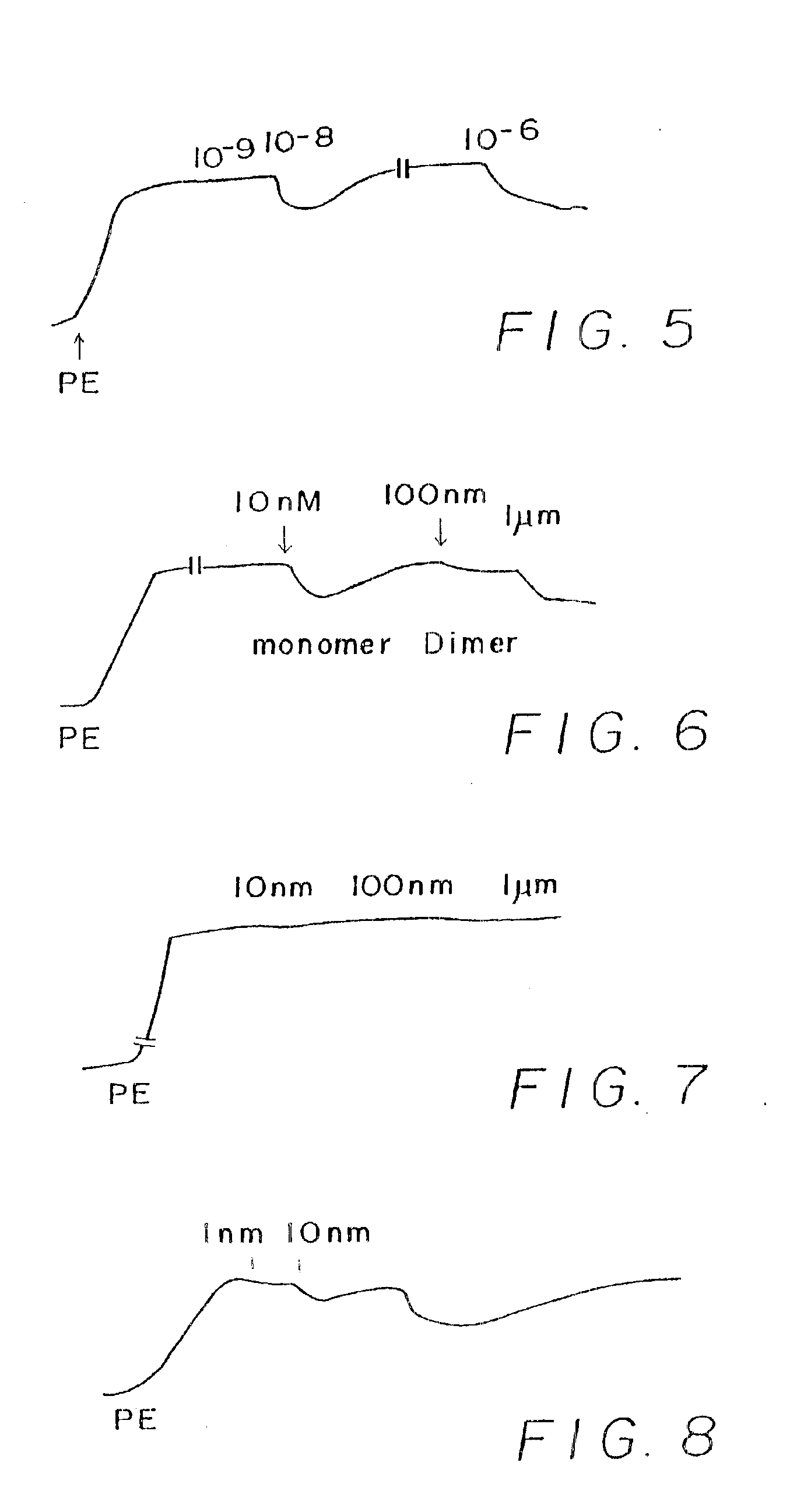

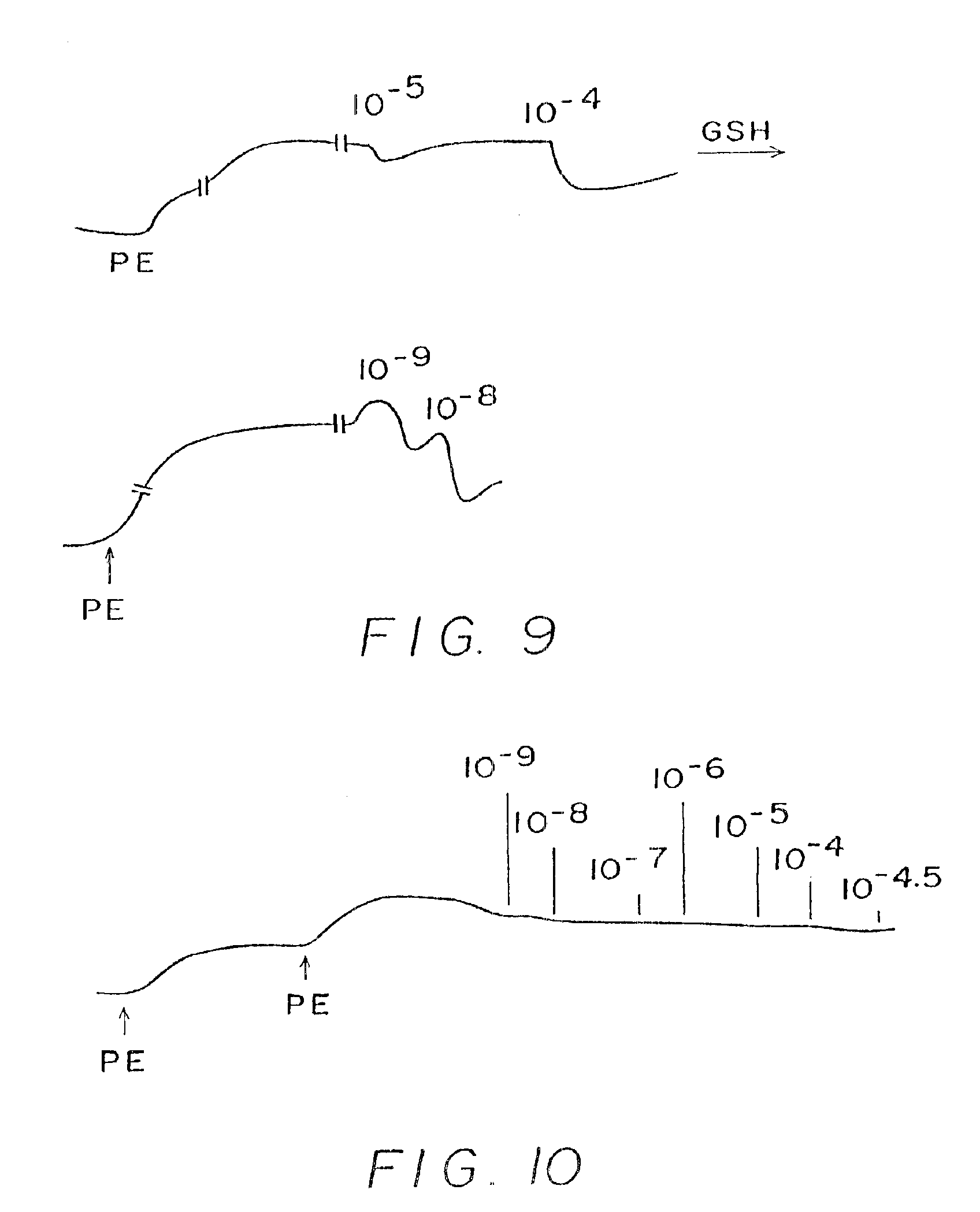

C-nitroso compounds and use thereof

InactiveUS6887994B2Inhibition productionReduce impactAntibacterial agentsOrganic chemistryNitrosoNo donors

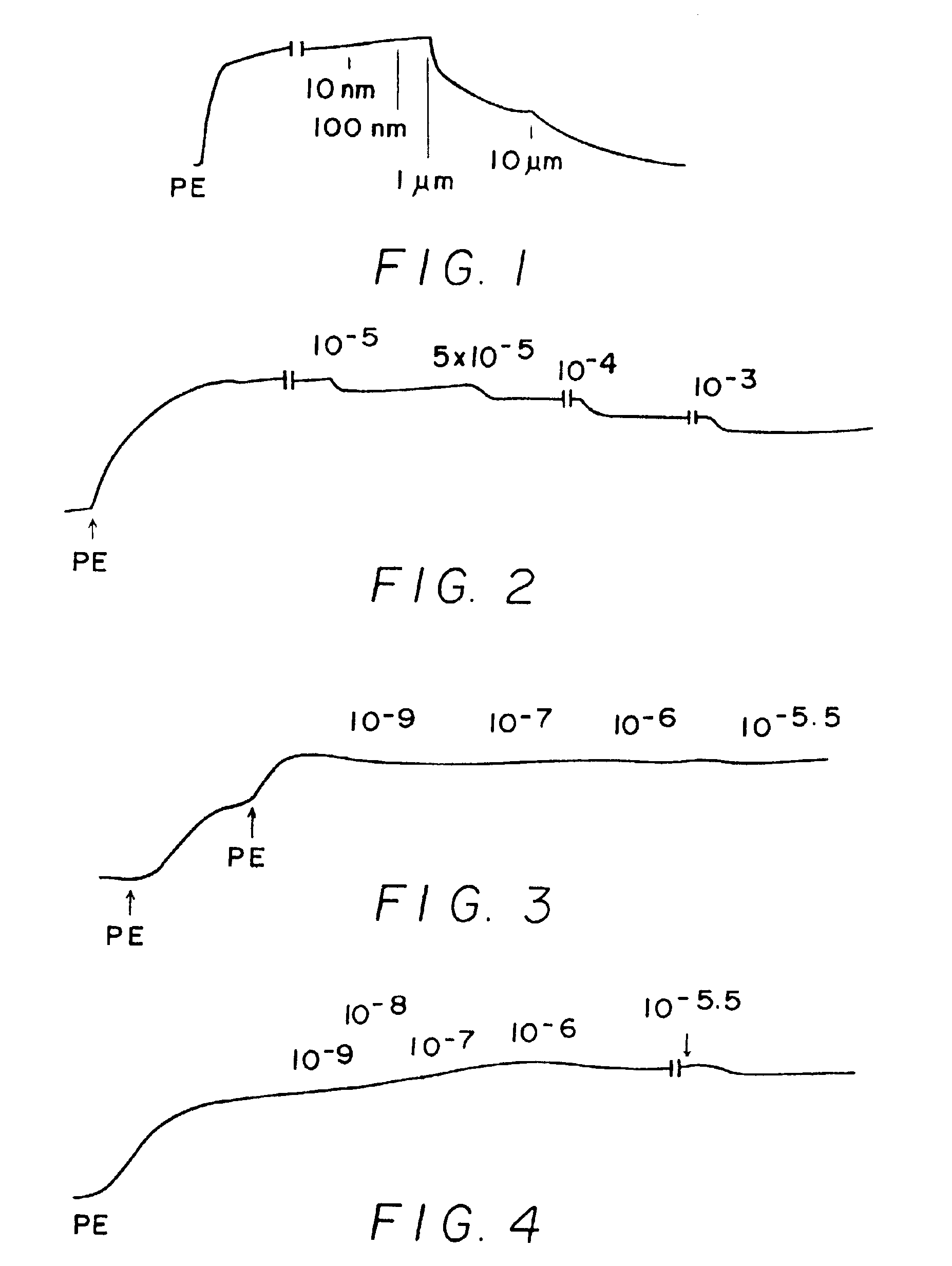

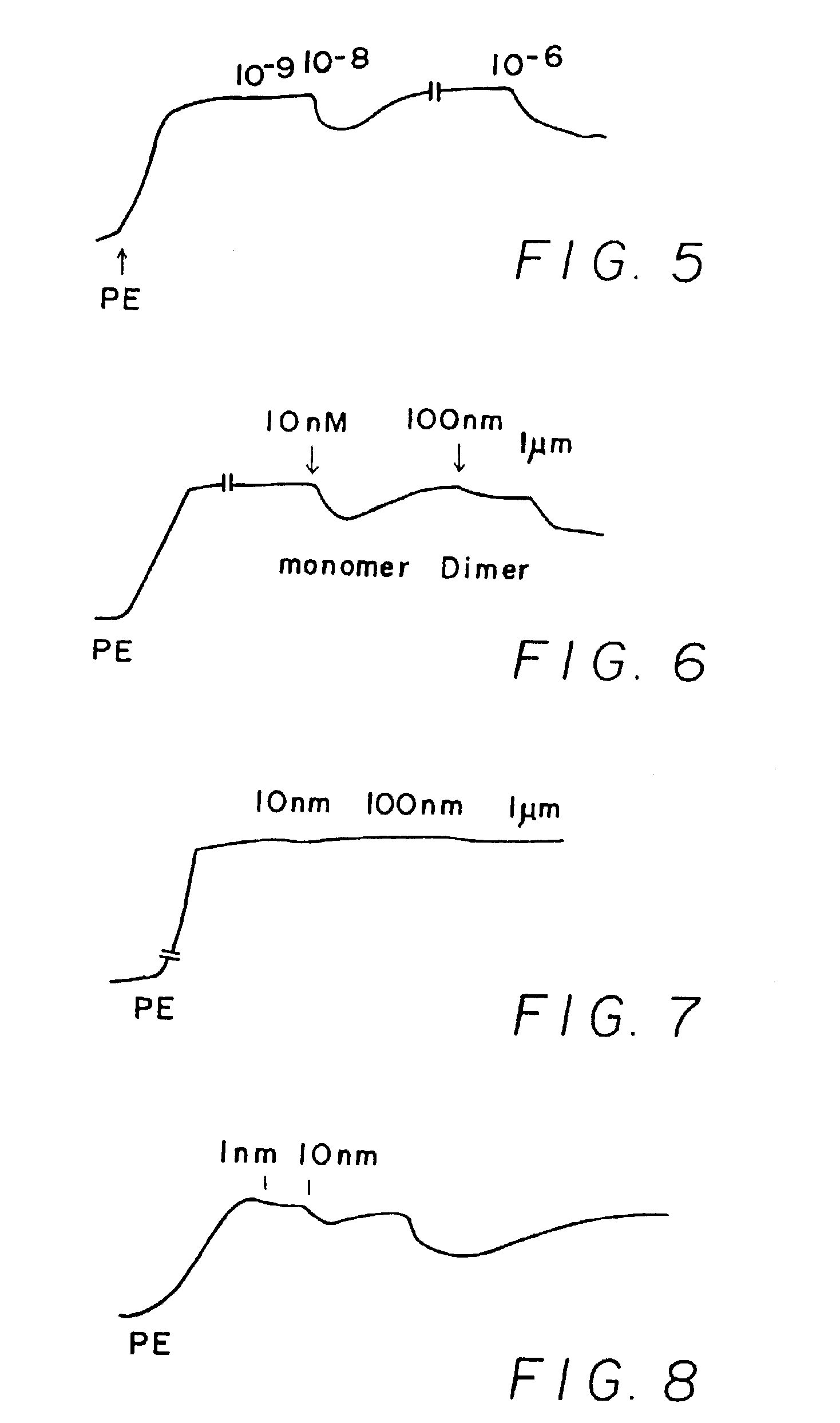

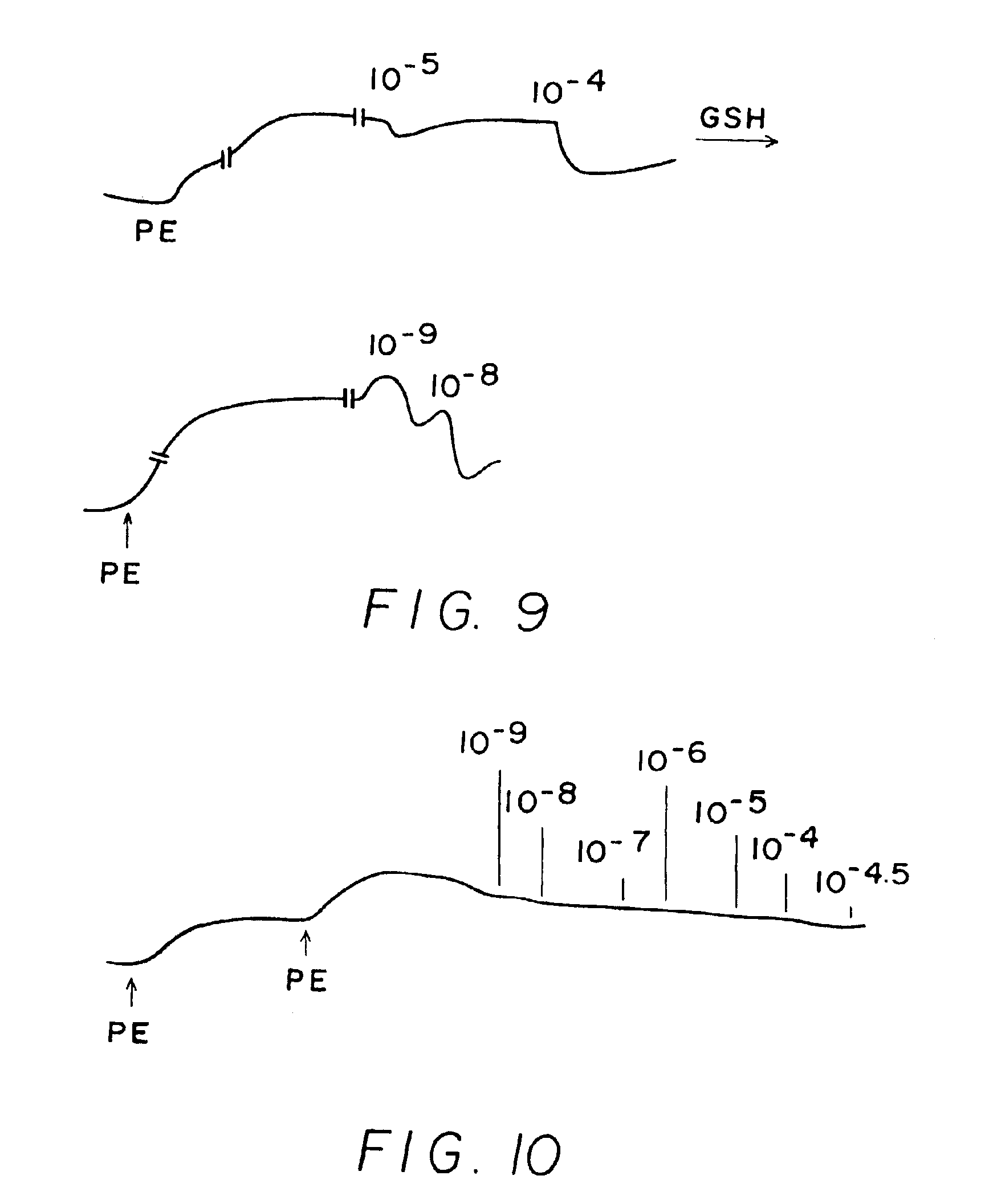

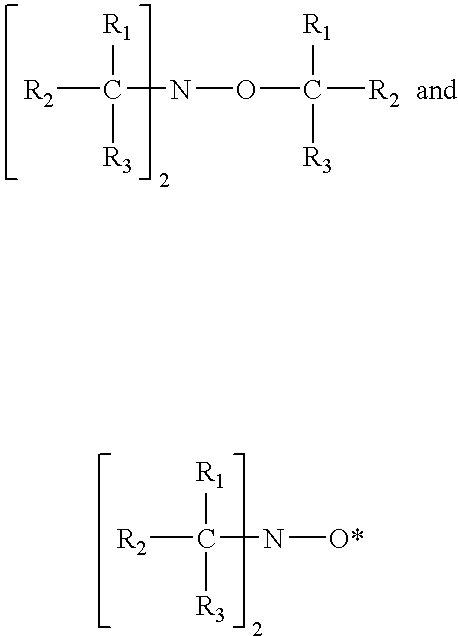

A C-nitroso compound having a molecular weight ranging from about 225 to about 1,000 (from about 225 to about 600 for oral administration) on a monomeric basis wherein a nitroso group is attached to a tertiary carbon, which is obtained by nitrosylation of a carbon acid having a pKa less than about 25, is useful as an NO donor. In another case, the C-nitroso compound contains the moiety—C—N(O)X—where X is S, O or NR. One embodiment is directed to COX-2 inhibitors where a tertiary carbon atom and / or an oxygen atom and / or a sulfur atom is nitrosylated.

Owner:DUKE UNIV

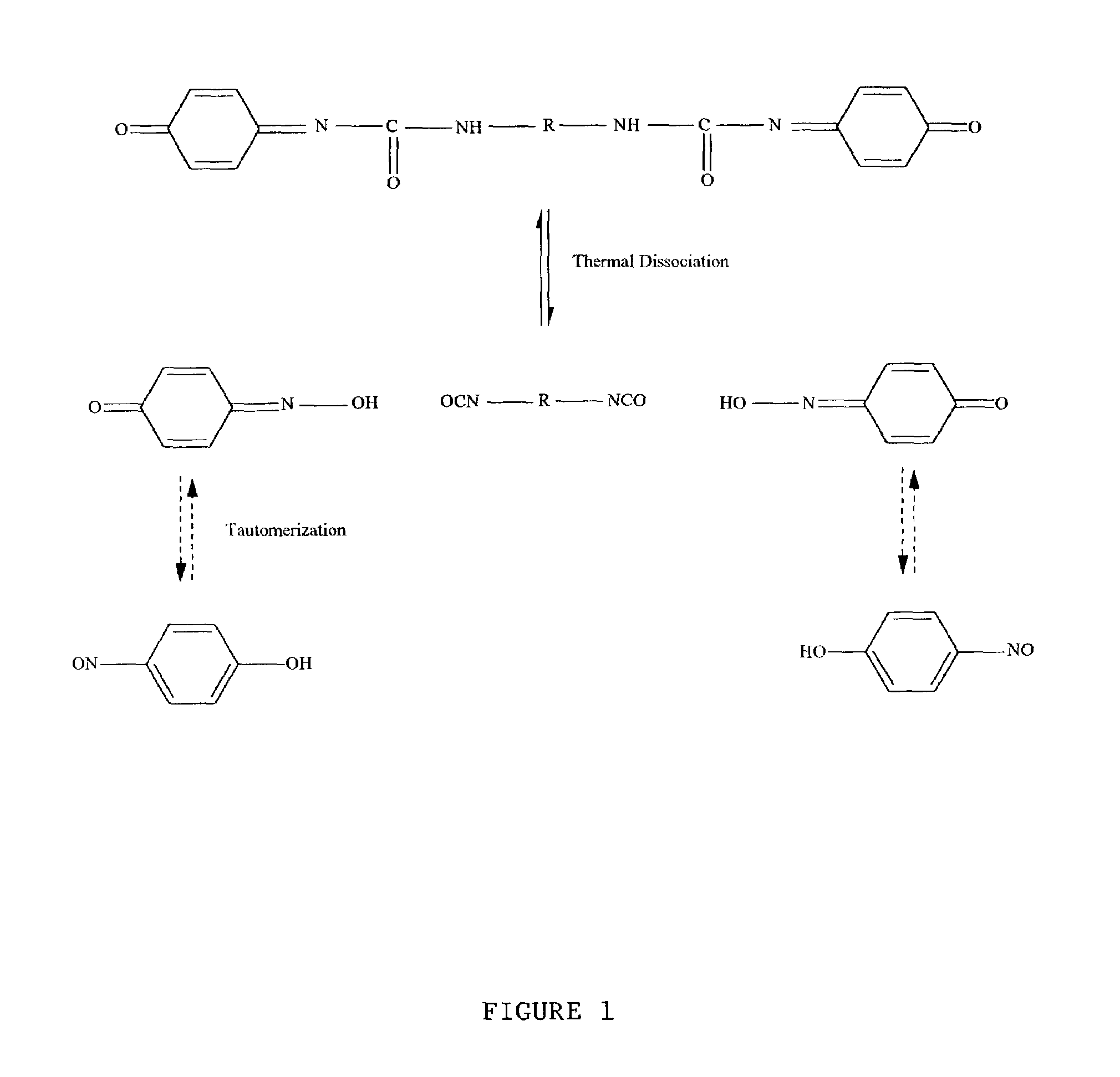

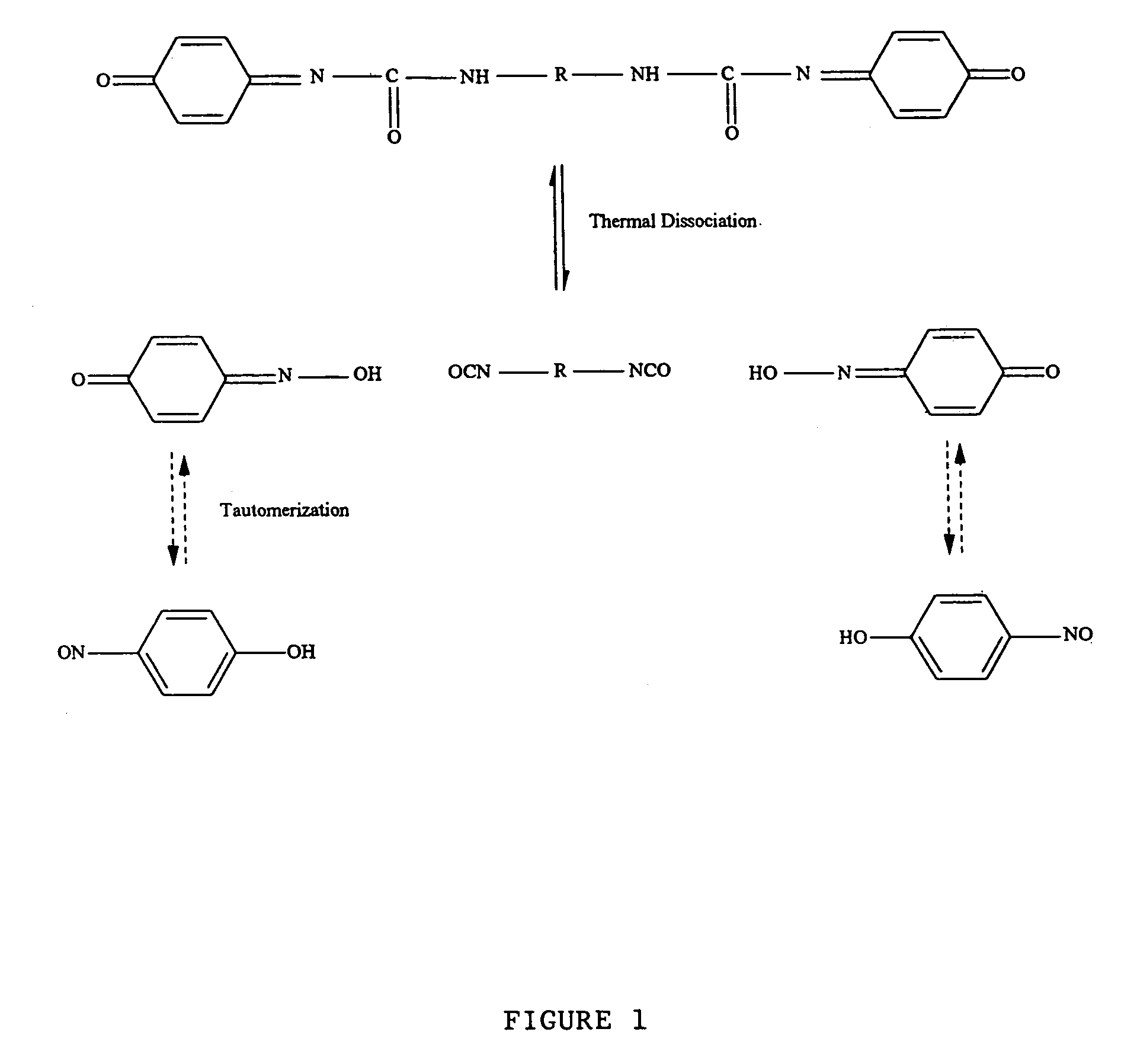

Urethane sporting equipment composition incorporating nitroso compound

Sports equipment incorporate thermoplastic compositions including urethane and a nitroso reaction product of a nitroso compound and a diisocyanate or polyisocyanate. The invention allows for the processing advantages of a thermoplastic urethane with the superior performance characteristics of a cross-linked polyurethane.

Owner:TAYLOR MADE GOLF

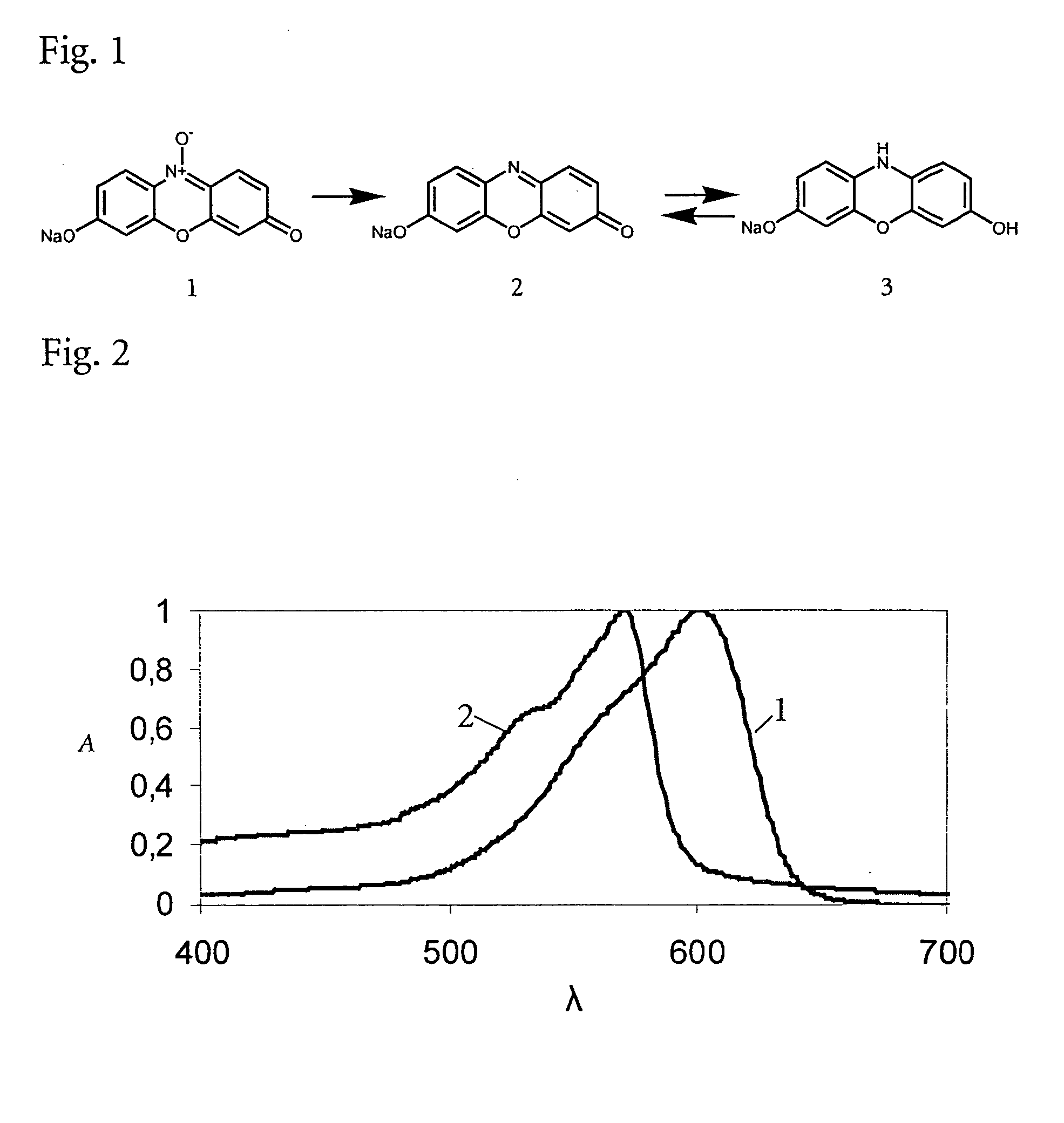

On-board control for analytical elements

InactiveUS20050123441A1Reliable indicationLong storageAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorMeasuring instrumentOn board

The invention concerns a reagent system for the so-called on-board control of analytical elements, in particular test strips, containing an organic N-oxide or a nitroso compound. The invention also concerns analytical elements containing a reagent system for a detection reaction and a reagent system for an on-board control. Furthermore, the invention concerns a method for checking analytical elements in which a reagent system for an on-board control is examined optically or electrochemically with the aid of a measuring instrument for changes which could indicate a stress of the analytical element.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

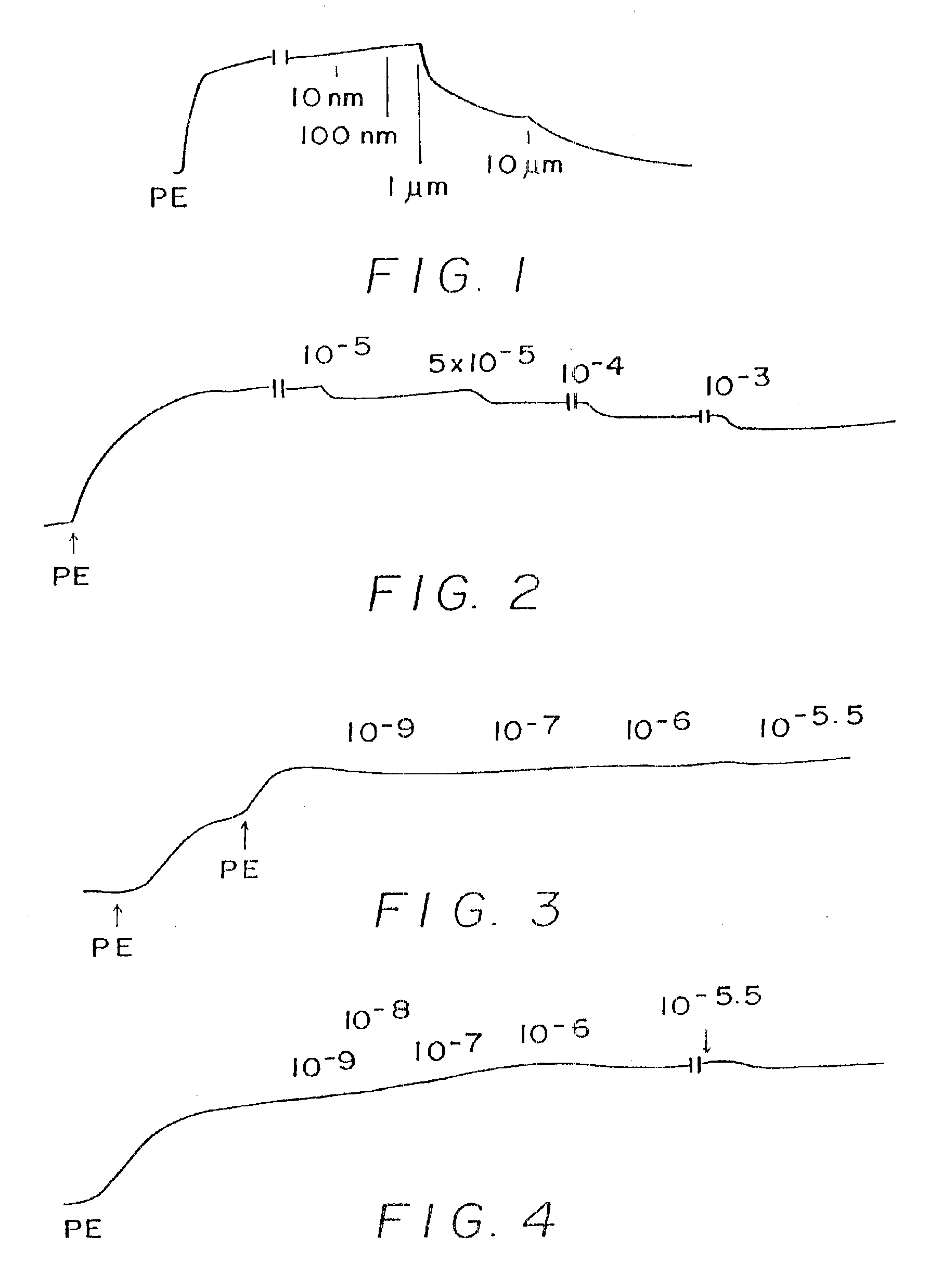

C-nitroso compounds and use thereof

InactiveUS20050187166A1Improve mitigation effectInhibition productionBiocideOrganic chemistryNitrosoOral medication

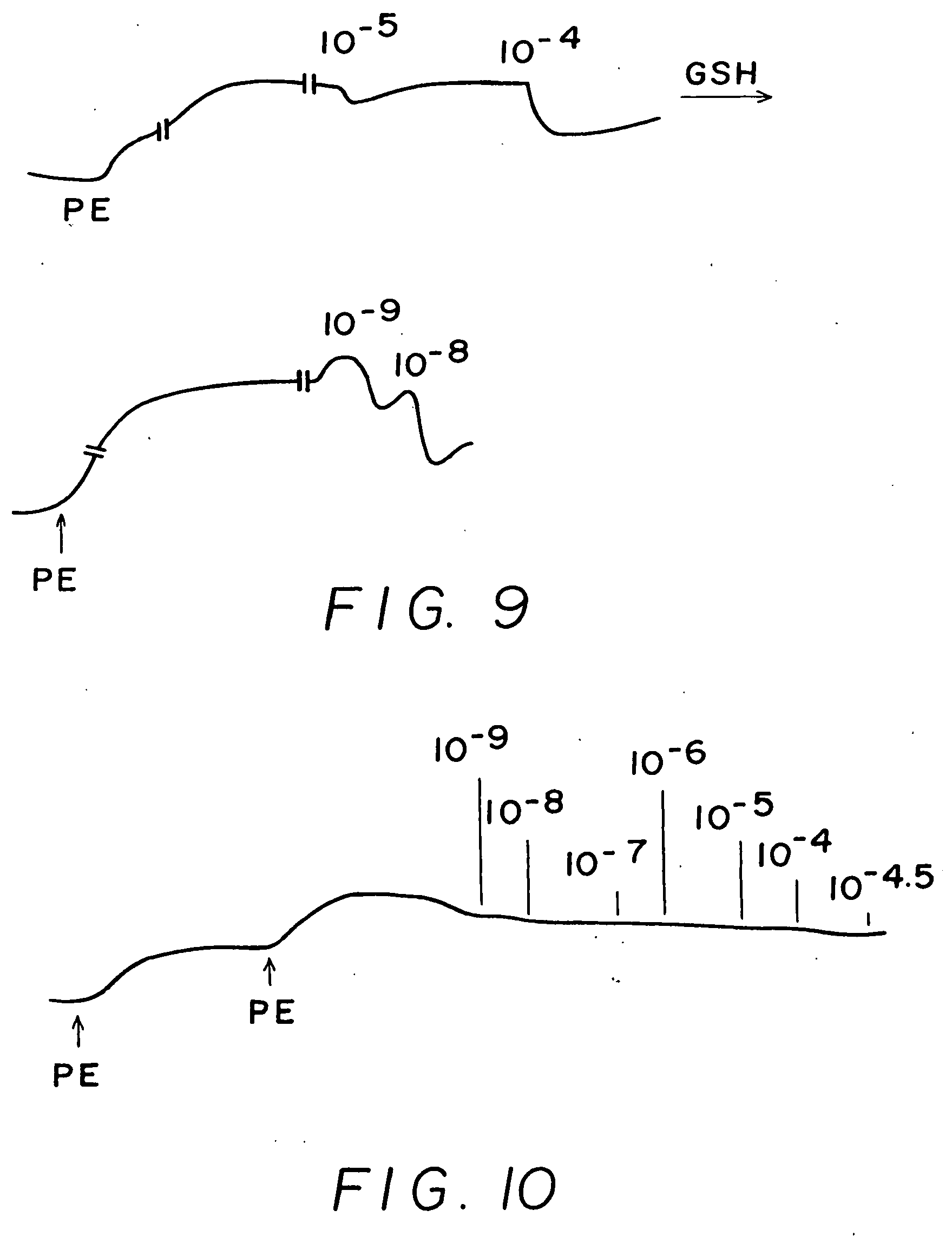

A C-nitroso compound having a molecular weight ranging from 225 to 1,000 (from 225 to 600 for oral administration) on a monomeric basis wherein a nitroso group is attached to a tertiary carbon, which is obtained by nitrosylation of a carbon acid having a pKa less than about 25, is useful as an NO donor. When the compound is obtained from a carbon acid with a pKa less than about 10, it provides vascular relaxing effect when used at micromolar concentrations and this activity is potentiated by glutathione to be obtained at nanomolar concentrations. When the compound is obtained from a carbon acid with a pKa ranging from about 15 to about 20, vascular relaxing effect is obtained at nanomolar concentrations without glutathione. In another embodiment, a biocompatible polymer incorporates a C-nitroso moiety.

Owner:DUKE UNIV

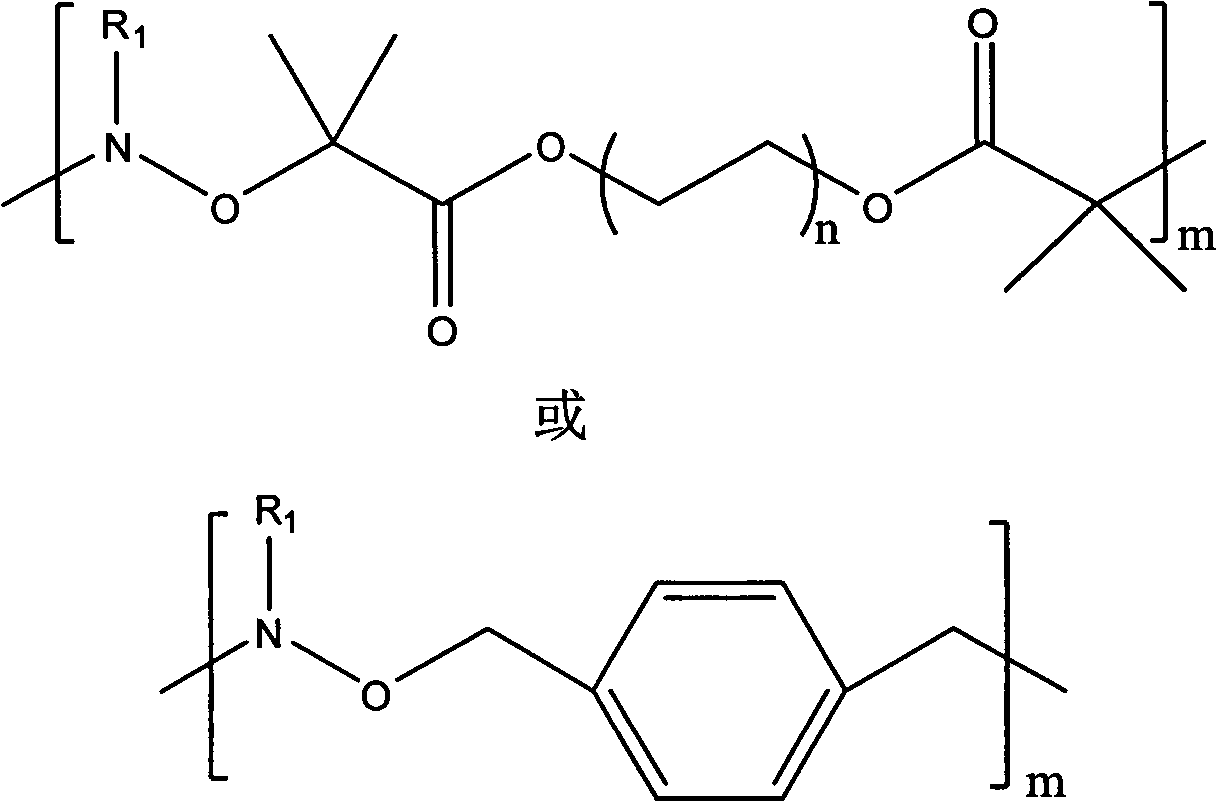

Polymers functionalized with nitroso compounds

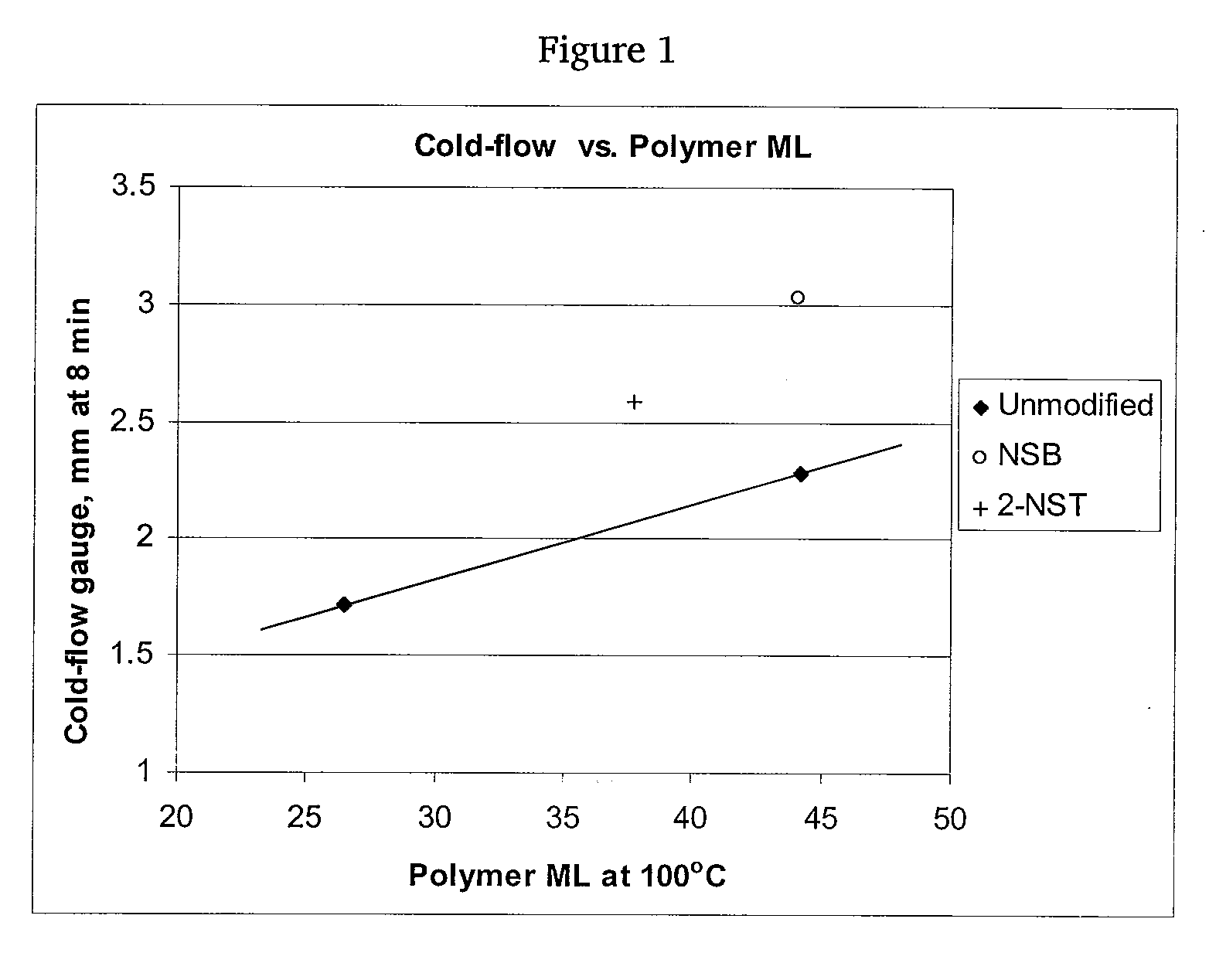

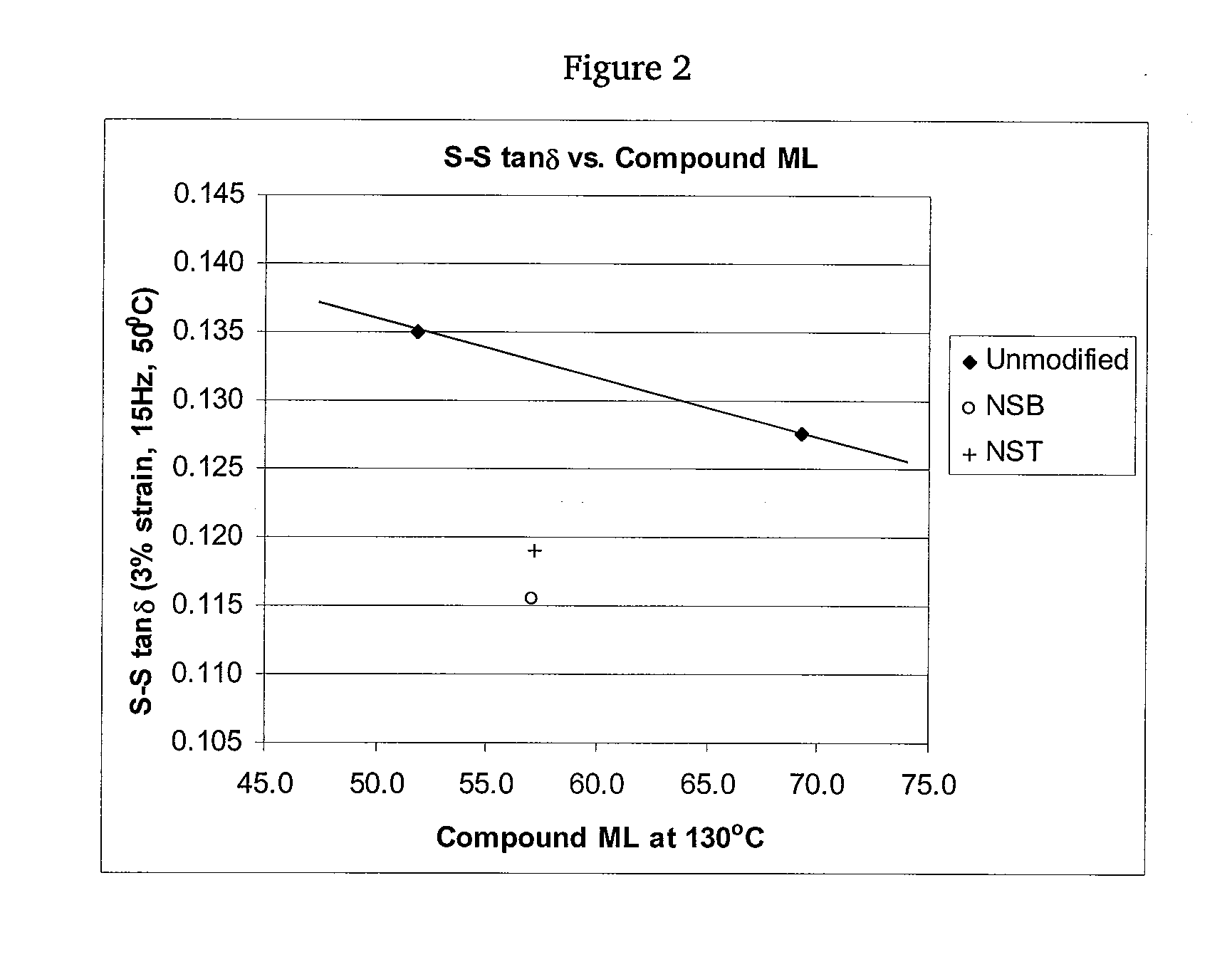

A method for preparing a functionalized polymer, the method comprising the steps of: (i) polymerizing monomer with a coordination catalyst to form a reactive polymer; and (ii) reacting the reactive polymer with a nitroso compound.

Owner:BRIDGESTONE CORP

Method for manufacturing sporting equipment incorporating urethane/nitroso composition

Sports equipment incorporate thermoplastic compositions including urethane and a nitroso reaction product of a nitroso compound and a diisocyanate or polyisocyanate. The invention on allows for the processing advantages of a thermoplastic urethane with the superior performance characteristics of a cross-linked polyurethane.

Owner:TAYLOR MADE GOLF

C-nitroso compounds and use thereof

A C-nitroso compound having a molecular weight ranging from 225 to 1,000 (from 225 to 600 for oral administration) on a monomeric basis wherein a nitroso group is attached to a tertiary carbon, which is obtained by nitrosylation of a carbon acid having a pKa less than about 25, is useful as an NO donor. When the compound is obtained from a carbon acid with a pKa less than about 10, it provides vascular relaxing effect when used at micromolar concentrations and this activity is potentiated by glutathione to be obtained at nanomolar concentrations. When the compound is obtained from a carbon acid with a pKa ranging from about 15 to 20, vascular relaxing effect is obtained at nanomolar concentrations without glutathione. In another embodiment, a biocompatible polymer incorporates a C-nitroso moiety.

Owner:DUKE UNIV

Method for rapidly pickling fish by mixed fermentation of microorganisms

ActiveCN103284225AInhibition of denaturationImprove permeabilityFood preparationNitro compoundMicroorganism

The invention discloses a method for rapidly pickling fish by mixed fermentation of microorganisms. According to the method, fresh fish or frozen fish is rapidly prepared into the pickled fish by the procedures of pre-treating fish bodies, pickling by a low-temperature wet pickling method, rinsing, inoculating a mixed microorganism fermenting agent, carrying out gradient low-temperature drying and the like, so that the time for pickling and processing the fishes can be shortened and the flavor of fish pickled products can be improved; nitrite and nitro compounds are prevented from being generated in a process of pickling the fish products, and the edible safety of the fish pickled products is guaranteed; the pickled fish processed by the method is good in flavor, is short in pickling time, low in salt content and free of the nitro compounds; the operation method is simple, the production cost is low, the energy consumption is low, the environmental pollution is small and the product quality is stable; and the economic benefits of manufacturing enterprises can be improved.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

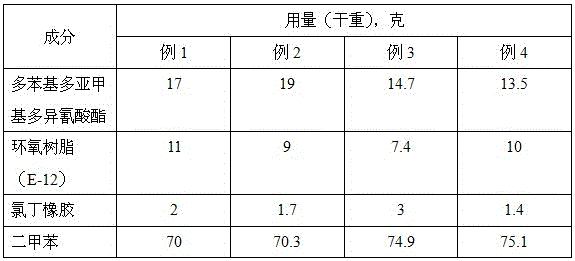

Environmentally preferred high solids, low viscosity flock adhesives

InactiveUS6924000B2Low in VOCsGood paintabilityLayered productsPolyureas/polyurethane adhesivesFiberElastomer

An environmentally preferred flock adhesive composition containing low molecular weight prepolymers of isocyanate terminated polyether and / or polyalkadiene polyols is disclosed. The prepolymers are free of residual volatile isocyanate (<1000 ppm) without blocking the isocyanate thereby providing favorable effects on viscosity, cure kinetics, and safety. The flock adhesive composition preferably contains an aromatic nitroso compound an epoxy novolak resin and a catalyst. The adhesive compositions can be made at high solids, with minimal co-solvent, while maintaining low viscosity, which is favorable to environmental regulations aimed at reducing solvent emissions. Furthermore, the solvents can be non-HAP and non-photochemically reactive. The adhesive composition can be utilized for the application of flocking fibers to various elastomer substrates.

Owner:LORD CORP

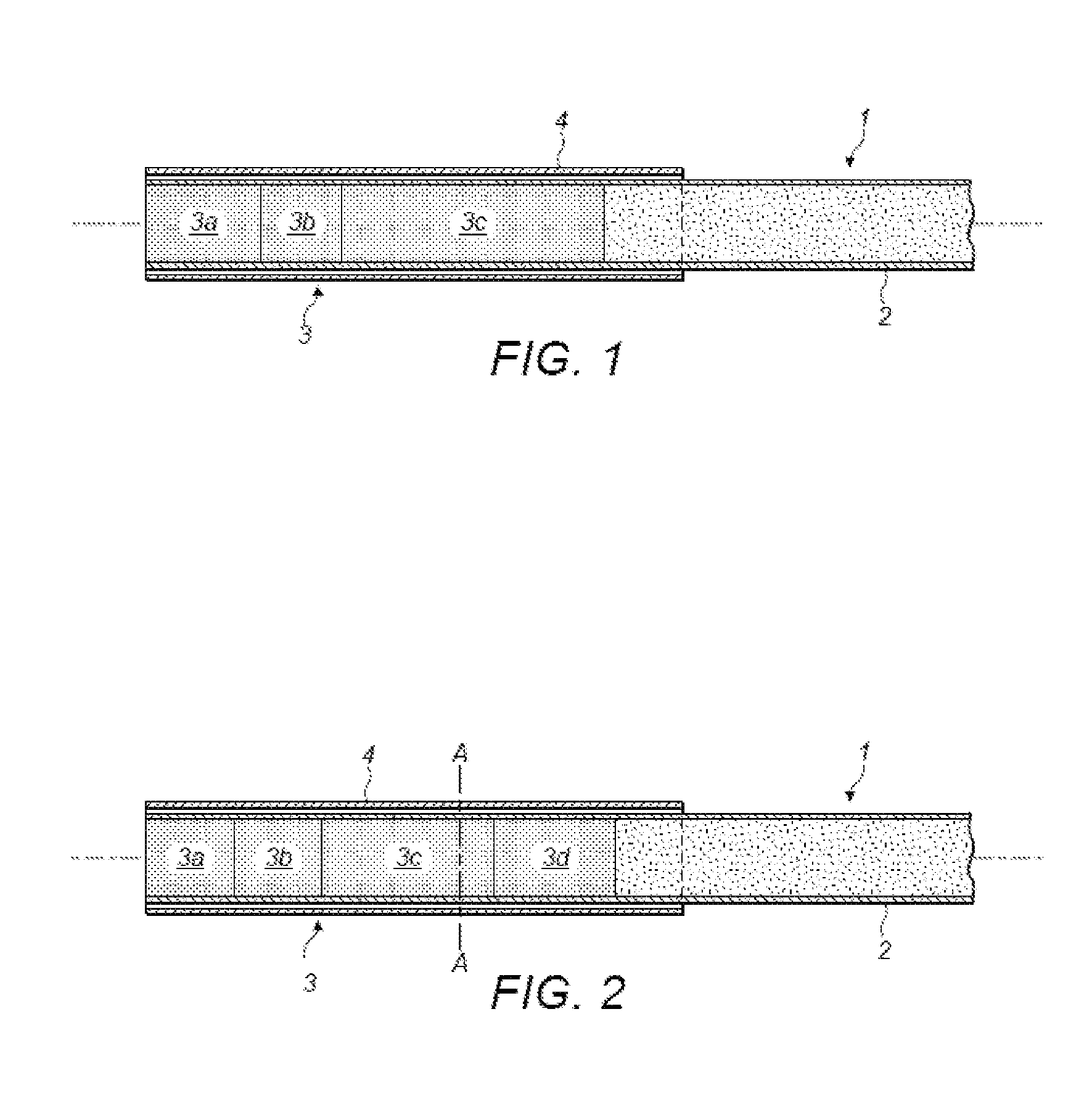

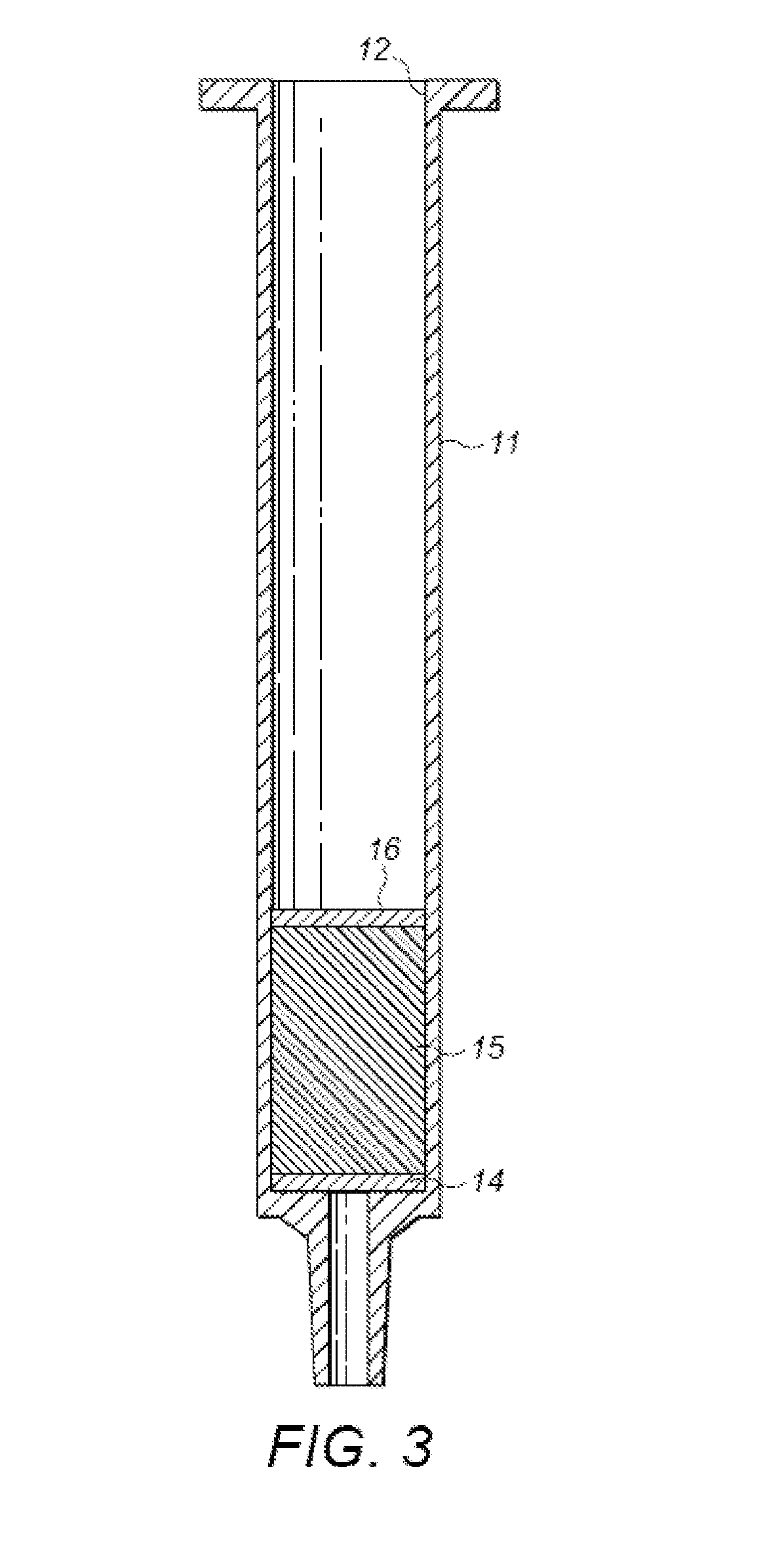

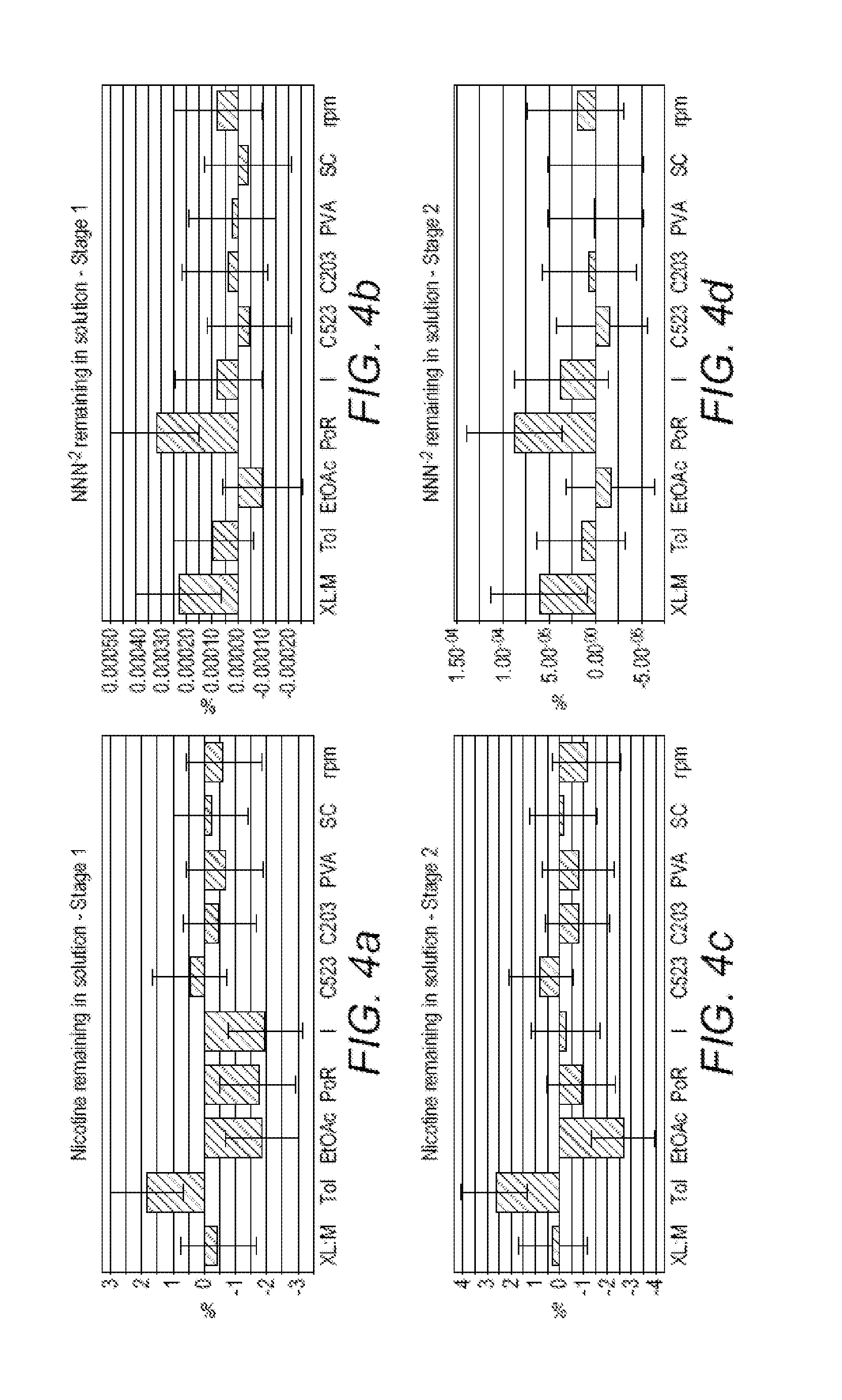

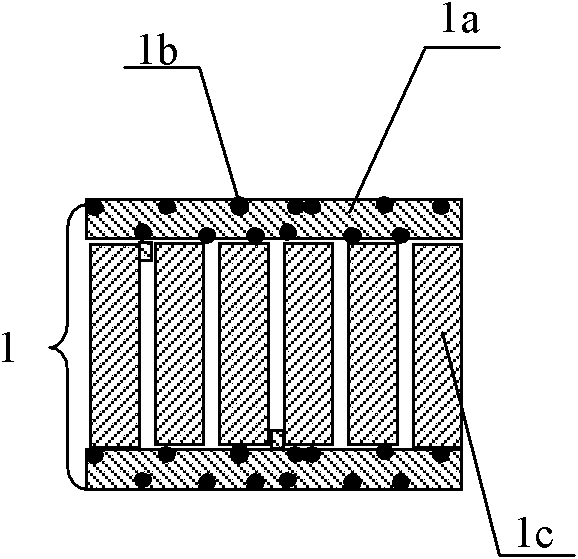

Polymers Selective for Nitro-Containing Compounds and Methods of Using the Same

Porous beads are provided of a polymer of a non-acidic monomer and a cross-linker having polar functionality, one of which is hydrophilic, the other of which is hydrophobic, further comprising residues of polyvinyl alcohol. The beads may be molecularly imprinted or non-molecularly imprinted. The use of such beads in the removal of nitroso-containing compounds from material containing them is also disclosed. Also disclosed is a non-molecularly imprinted polymer which is selectively adsorbent for at least one tobacco specific nitrosamine in the presence of nicotine, said polymer being a polymerization product of a non-acidic monomer and a cross-linker having polar functionality, one of which is hydrophilic, the other of which is hydrophobic.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

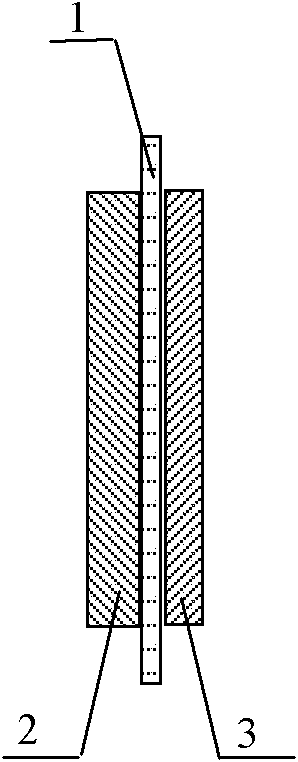

Diaphragm and method for preparing composite electrode couple by utilizing diaphragm

ActiveCN102437304AReduce cloggingCell electrodesCell component detailsPorous substratePolymer adhesive

The invention discloses a diaphragm and a method for preparing a composite electrode couple by utilizing the diaphragm, and belongs to the technical field of lithium ion batteries. The diaphragm comprises a porous substrate and nonporous or low-porosity coatings on the two surfaces of the porous substrate, wherein the nonporous or low-porosity coating is formed by a forming agent and a polymer adhesive; and the foaming agent may be one or more of an azo foaming agent, a nitroso compound foaming agent and a sulfonyl hydrazide foaming agent. In the method for preparing the composite electrode couple, the composite electrode couple is prepared by coating a cathode mixture comprising a cathode active material, a conductive agent and the adhesive on one surface of the diaphragm, coating an anode mixture comprising an anode active material, the conductive agent and the adhesive on the other surface of the diaphragm, and foaming the foaming agent. By the diaphragm and the method, the probability of forming internal short circuit by direct contact between the cathode active material and the anode active material in a composite electrode couple preparation process can be avoided or decreased.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Processing rubber to metal adhesive

InactiveUS20060014867A1Non-macromolecular adhesive additivesLayered productsPolymer sciencePolyolefin

Disclosed is a rubber-metal adhesive in the form of dispersed solids in a volatile liquid carrier, with a specified pigment grind and is sprayable at uniform film coatings on metal surfaces at 25±2 solids content wt. % and a viscosity of from 50 to about 500 cps (Brookfield LVT 2 @ 30 rpm). The adhesive comprises a dispersion of solid particles comprising nitroso compound, halogenated polyolefin, acid acceptor and from 5% to 35 wt. % of inert, incompressible, spheroidal particles having a BET surface area of from 0.1 to 10 m2 / g and a 50th percentile particle diameter (D50) of 5 to 25 μm.

Owner:LORD CORP

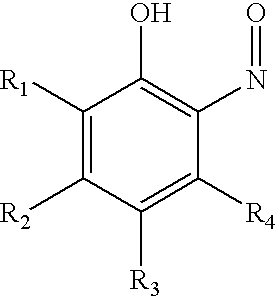

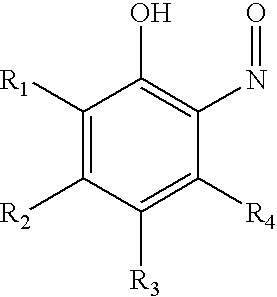

Ortho-nitrosophenols as polymerization inhibitors

InactiveUS20060283699A1Prevent premature polymerizationEffective inhibiting amountGroup 4/14 element organic compoundsOrganic compounds purification/separation/stabilisationNitrosoHalogen

Disclosed herein is a method for inhibiting the premature polymerization of ethylenically unsaturated monomers comprising adding to said monomers an effective amount of at least one nitroso inhibitor of the structure: wherein R1, R2, R3, and R4 are independently selected from the group consisting of hydrogen, nitro, nitroso, halogen, COOR wherein R is hydrogen or alkyl, alkyl, and heteroatom-substituted alkyl; or adjacent groups R1, R2, R3, and R4 can be taken together to form a substituted or unsubstituted fused six-membered ring. Also disclosed is a composition of matter comprising: A) an ethylenically unsaturated monomer and B) at least one nitroso compound of the above-described structure.

Owner:ADDIVANT USA

Adhesive composition, method for bonding to a metal surface and rubber to metal adhesive

ActiveCN1969025ANon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentPolyolefinPolymer science

Owner:LORD CORP

An additive cigarette production technology

InactiveCN1543884AImprove stabilityNo effect on tasteTobacco treatmentCigar manufactureNitrosoNitroso Compounds

The invention relates to an addition agent for lowering the content of N-nitroso compound in cigarette and the cigarette production process, wherein the addition agent is a plant polyphenol microcapsule with plant polyphenol as the core, and alpha-cyclodextrin or beta-cyclodextrin or hydroxypropyl beta-cyclodextrin is used as molecular embedding agent for charging plant polyphenol microcapsule into the molecular embedding agent, forming stabilized colloid, by dissolving the colloidal solution and adding into the shredded tobacco, the content of N-nitroso compound in cigarette can be substantially reduced.

Owner:李波

Mesopore solid alkali, mesopore functional material, its preparation method and application

InactiveCN1460641AGood dispersionReach friendlyMolecular sieve catalystsOther chemical processesNitrosoMolecular sieve

The present invention relates to a mesopore solid alkali and functional material. It is a mesopore silicon molecular sieve containing rare earth metal or transition metal atom and whose grain size is 4-10 nm, and has the mesopore silicon molecular sieve with alkali strength of 9.3-22.5. Said invented mesopore solid alkali and functional material can be used as cigarette additive capable of reducing nitrosamine content in the cigarettes smoke, and the total content of nitroso compound in the fire holding capacity of cigarette can be reduced by 30-47%.

Owner:NANJING UNIV

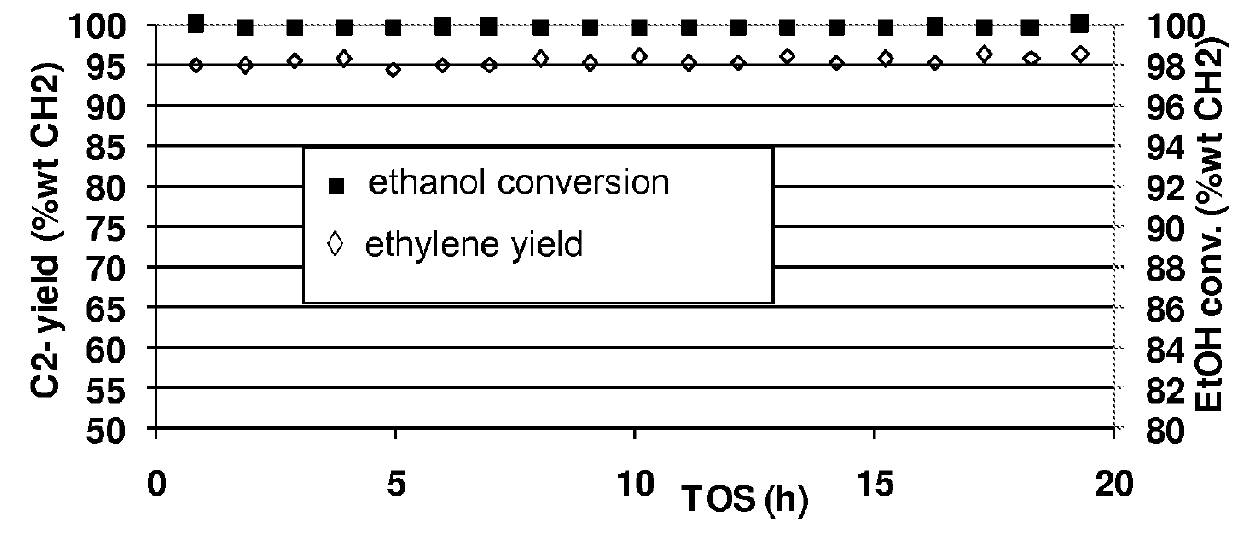

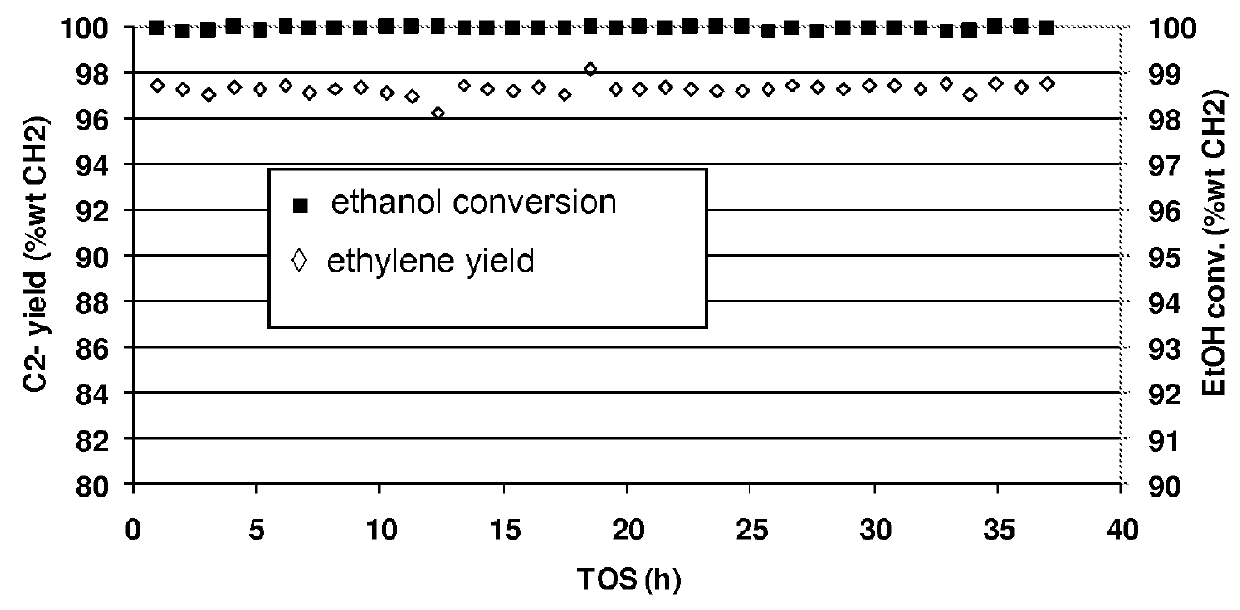

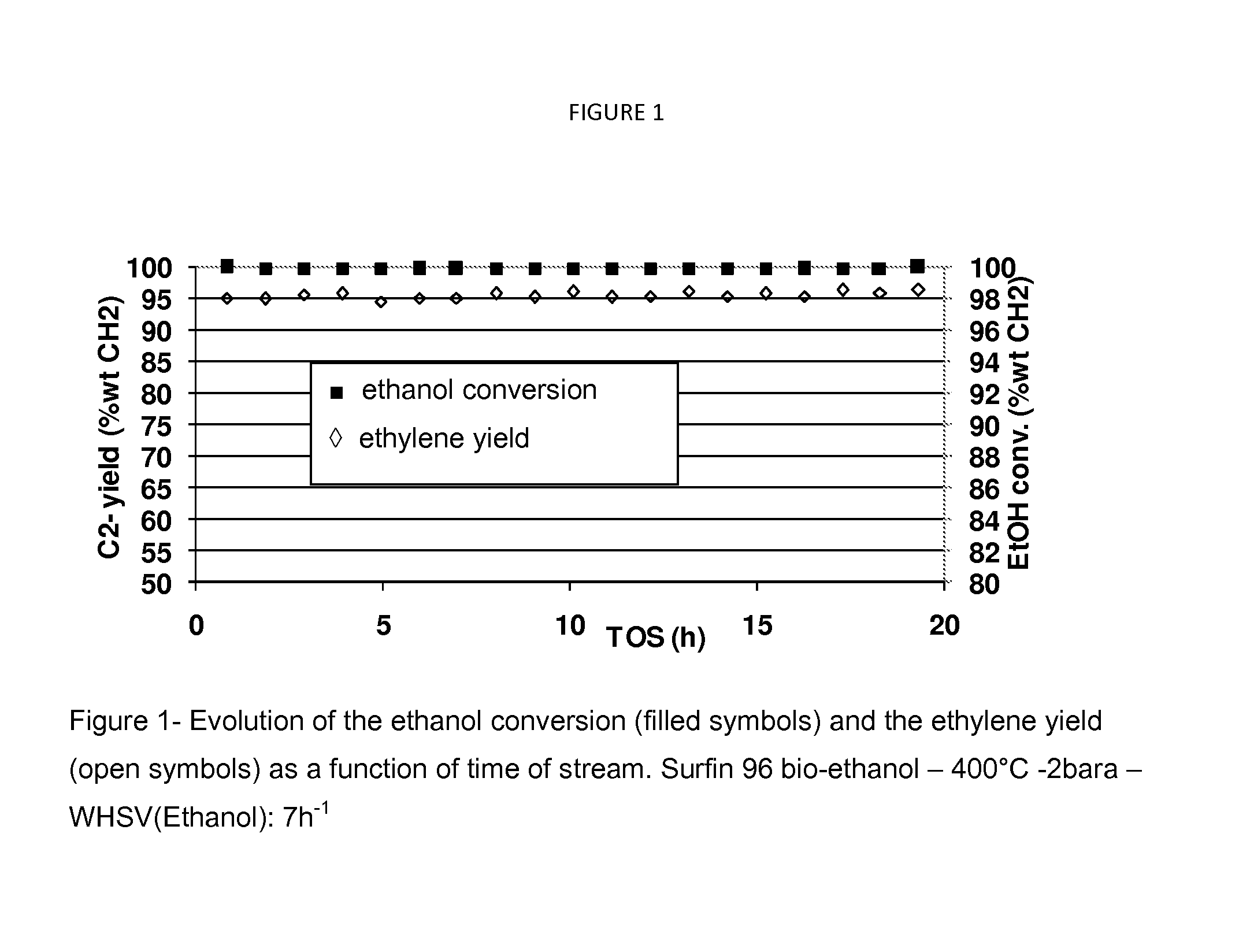

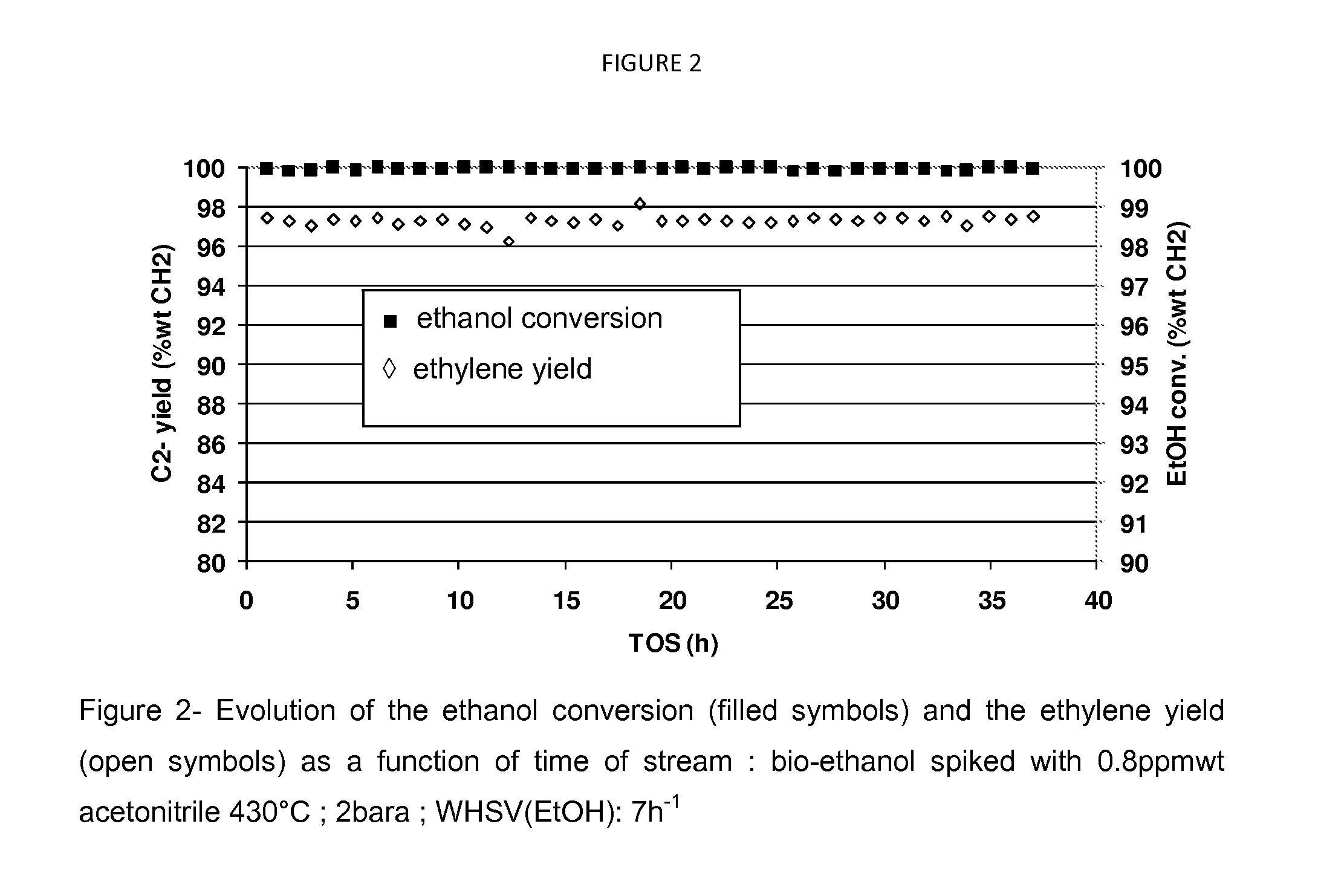

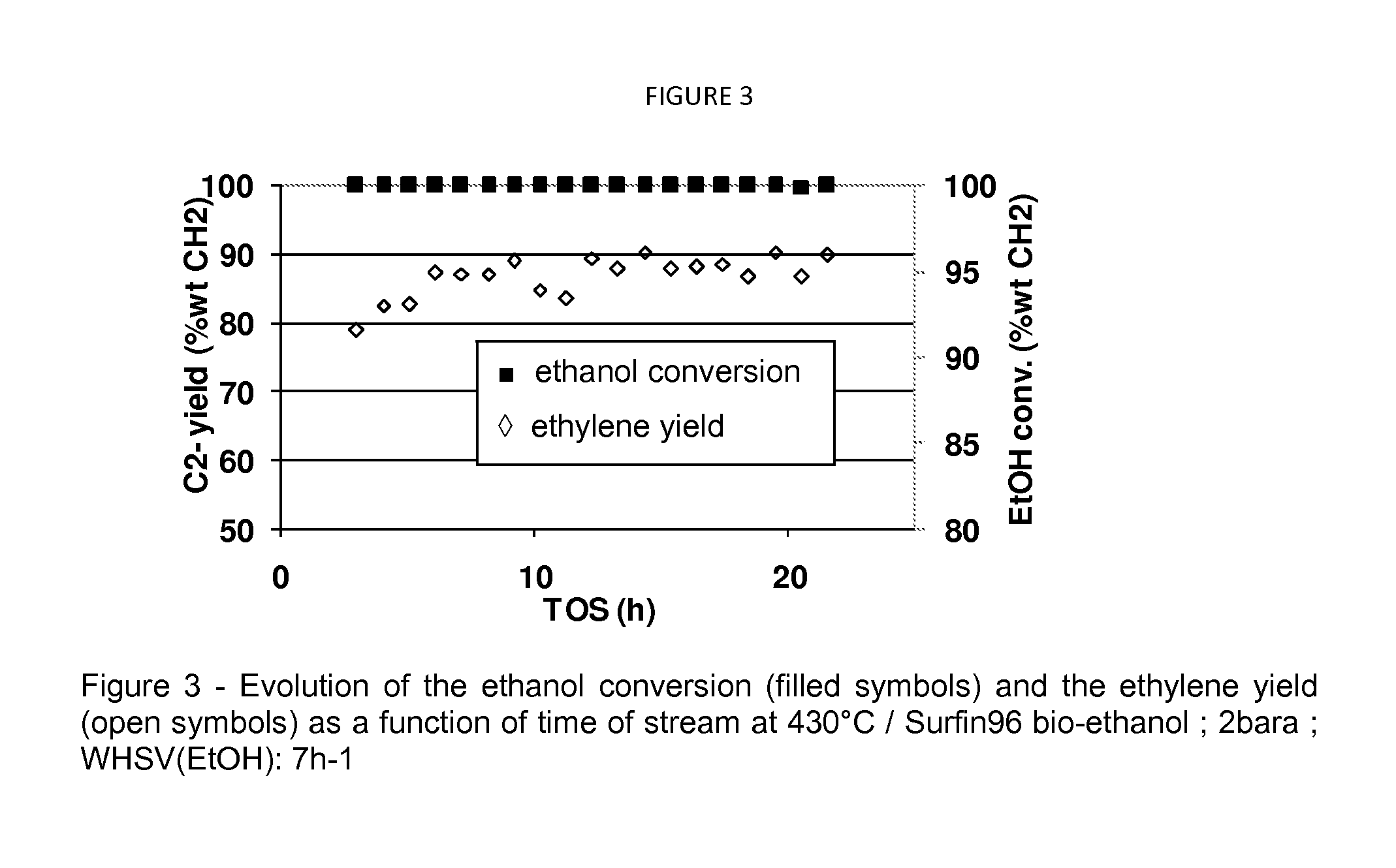

Dehydration of alcohols on acidic catalysts

ActiveUS9249066B2High selectivityMolecular sieve catalystsMolecular sieve catalystKetoneAlkyl nitrites

A dehydration process may include introducing in a reactor an alcohol, and contacting the alcohol with an acidic catalyst to dehydrate the alcohol to make a corresponding olefin. The process may include recovering from the reactor the olefin and water. In the process, an effective amount of a component capable to neutralize a part of the catalyst active site may be introduced. The component may include ammonia, organic ammonium salts, hydrazine, nitriles, amines, amides, imines, di-imines, imides, cyanates, isocyanates, nitrites and nitroso compounds, aldehydes, ketones, carboxylic esters, and their corresponding thio-compounds.

Owner:TOTAL RES & TECH FELUY

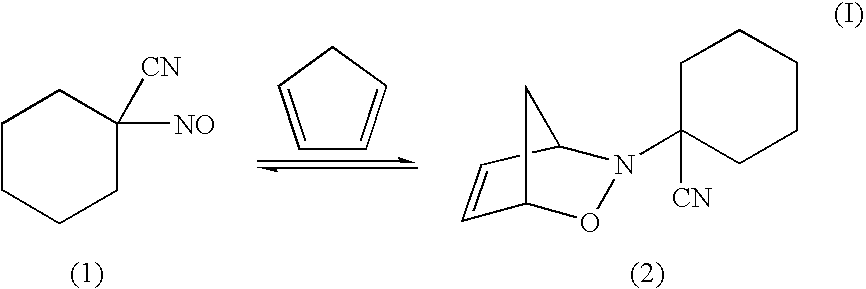

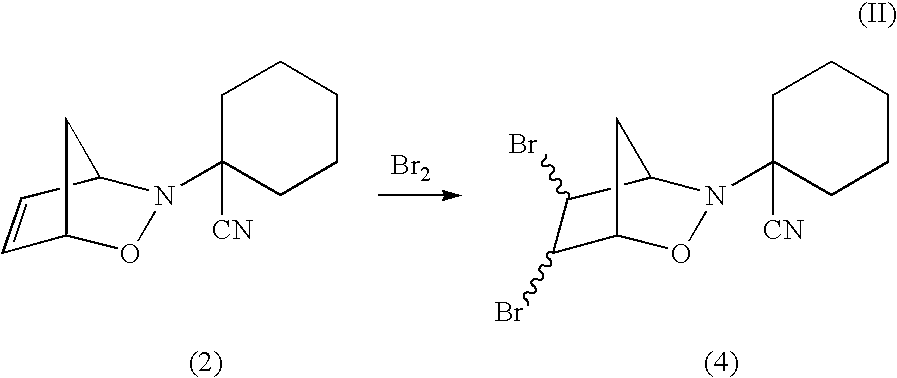

Stable neutral nitric oxide source

C-nitroso compound capable of releasing neutral nitric oxide is made stable by forming a Diels Alder adduct thereof which is functionalized at the Diels-Alder double bond to impart the stability. Treatment of the stabilized adduct with agent that removes functionalization and regenerates Diels Alder double bond triggers delivery of neutral nitric oxide via retro Diels-Alder reaction and homolytic scission.

Owner:DUKE UNIV

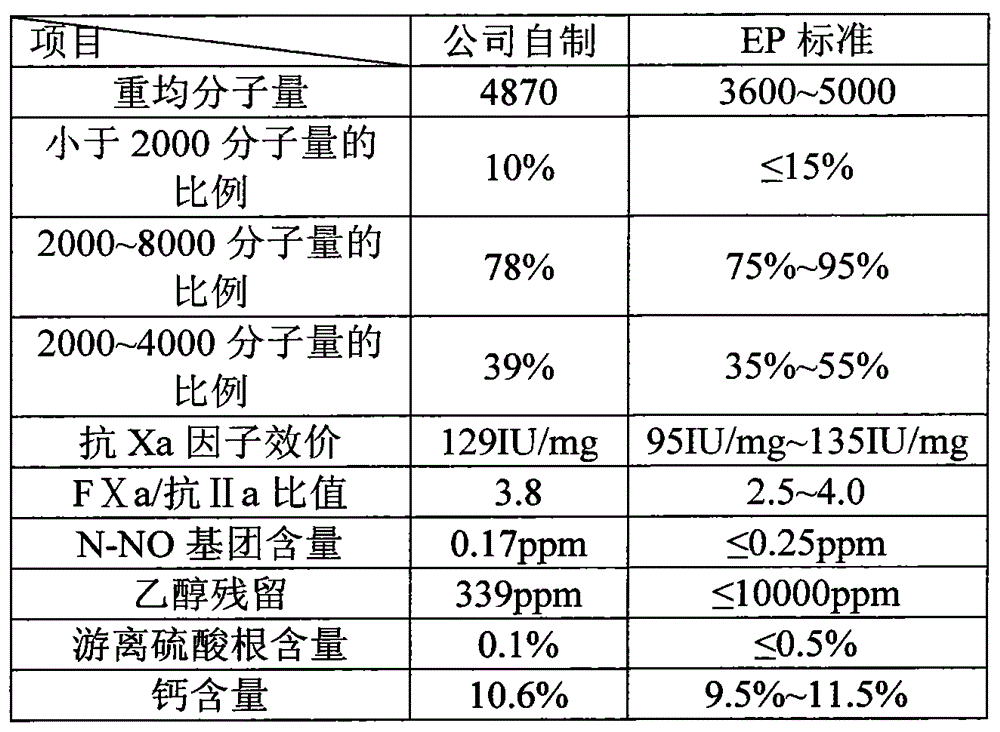

Preparation process of nadroparin calcium

ActiveCN104086673AHigh activityHighly Active Nadroparin Calcium Product, Product QualityAntipyreticAnalgesicsNitro compoundFreeze-drying

The invention relates to a preparation process of nadroparin calcium. The preparation process comprises the following steps: S1, degrading heparin sodium; S2, reducing degradation liquid; S3, performing ultraviolet radiation, namely radiating reduction liquid by using an ultraviolet lamp to remove residual nitro compounds from the reduction liquid and reduce the content of N-NO groups; S4, performing calcium conversion and concentration, namely performing ultrafiltration on an ultrafiltration membrane by using a 5% calcium chloride solution, and concentrating the reduction liquid until the solid-liquid ratio is 1:10; S5, performing anion exchange chromatography, namely performing chromatography by adopting anion exchange resin, and collecting elution liquid; S6, freeze-drying to obtain nadroparin calcium. According to the process, the molecular weight of low-molecular-weight heparin calcium is controlled through the anion exchange chromatography, so that the molecular weight can be accurately controlled within 1% and the yield can be increased to more than 50%; moreover, the automation degree is high and the operation is convenient, so that a powerful guarantee is provided for increasing the production capacity.

Owner:CHANGZHOU QIANHONG BIOPHARMA

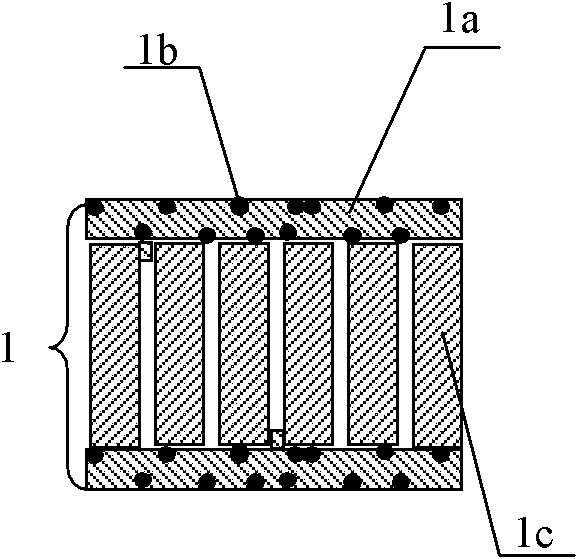

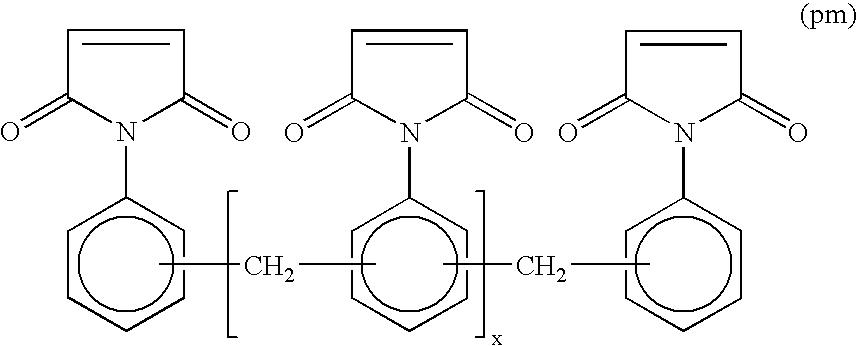

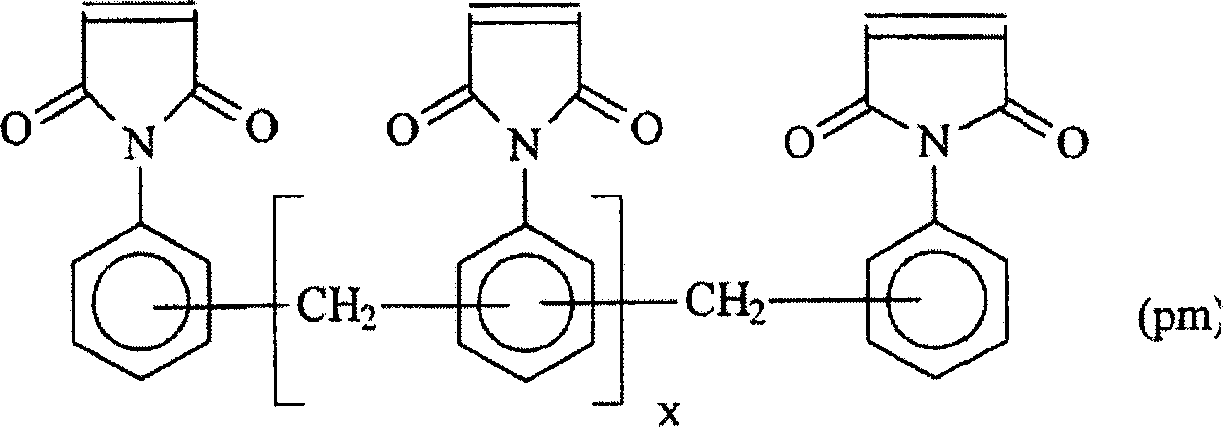

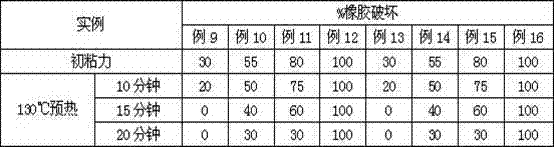

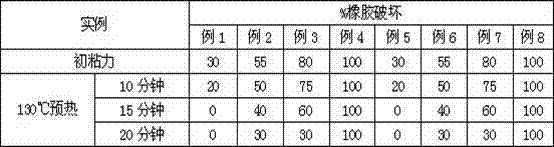

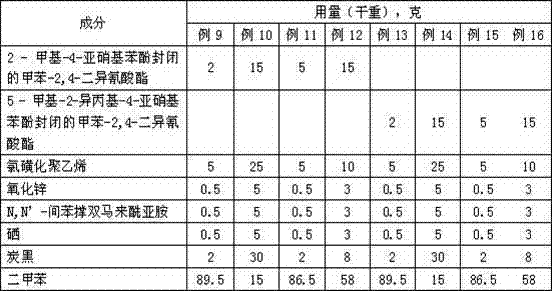

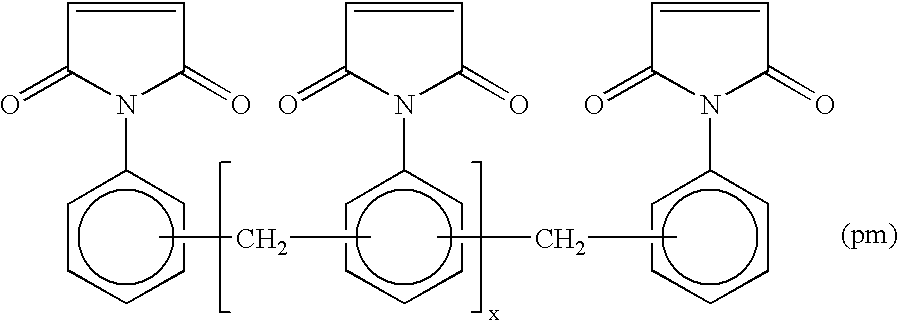

Heat vulcanization adhesive for bonding vulcanized rubber or thermoplastic rubber with hard panel

ActiveCN103045149AToxicHas "preheat resistance" performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesVulcanizationPolymer science

The invention discloses a heat vulcanization adhesive for bonding vulcanized rubber or thermoplastic rubber with a hard panel. The heat vulcanization adhesive contains single-nitrosophenol-closed methylbenzene-2,4-diisocyanate, halogenated rubber, metal oxide such as zinc oxide or magnesium oxide, an inertia pigment filler such as carbon black or titanium dioxide, a solvent such as aromatic hydrocarbon, a chloridized solvent or a ketone solvent, a polymaleimide compound such as N,N'-interphenylene bismaleimide or diphenylmethane bismaleimide and a vulcanizer such as sulphur, selenium or tellurium. The heat vulcanization adhesive disclosed by the invention has the greatest characteristic that the single-nitrosophenol-closed methylbenzene-2,4-diisocyanate is contained, so that an aromatic polynitro compound easy to sublimate or a highly toxic polyisocyanate monomer is not used; and the heat vulcanization adhesive has 'preheating-resistant' performance or is applicable to requirements of an injection moulding process.

Owner:SHANGHAI TONTEE NEW MATERIAL TECH

Method for preparing carbon nano tube/rubber nano composite matcrial by non-acidation treatment

The invention relates to a method to manufature carbon nm tube / rubber nm compounding material. The carbon nm tube directly reacts with polysulfide under the condition of the existing of nitroso compounding. The polysulfide covalence is grafted on the surface of the nm tube, the carbon nm tube and rubber molecules are covalence combined by sulphur atoms, the polymer molecules is covalence grafts on the tube surface of the carbon nm tube. The nm compounding material is manufactured by covalence grafting the carbon nm tube and the rubber. The invention could improve the dispersibility of carbon nm tube in rubber.

Owner:SHANGHAI JIAO TONG UNIV

Dehydration of alcohols on acidic catalysts

ActiveUS20130217943A1Resistance against poisoningReducing adsorption equilibriumMolecular sieve catalystsMolecular sieve catalystBisulfideHydrazine compound

The present invention is a process for the dehydration of an alcohol having at least 2 carbon atoms to make the corresponding olefin, comprising:a) introducing in a reactor a stream (A) comprising at least an alcohol, optionally water, optionally an inert component,b) contacting said stream with an acidic catalyst in said reactor at conditions effective to dehydrate at least a portion of the alcohol to make an olefin,c) recovering from said reactor a stream (B) comprising:the inert component and at least an olefin, water and optionally unconverted alcohol,d) optionally fractionating the stream (B) to recover the unconverted alcohol and recycling said unconverted alcohol to the reactor of step a),e) optionally fractionating the stream (B) to recover the inert component, water and the olefin and optionally recycling said inert component and optionally a part of the water to the reactor of step a),wherein,f) an effective amount of a component capable to neutralize a part of the catalyst active site is introduced in stream (A) or directly in the dehydration reactor andg) optionally the temperature of the dehydration reactor is adjusted to increase the alcohol conversion or the olefin yield or both.In another embodiment at step f) an effective amount of a component capable to increase the selectivity for the desired corresponding olefin is introduced in stream (A) or directly in the dehydration reactor.The component introduced at step f) can be chosen from the group consisting of ammonia, organic ammonium salts, hydrazine, nitriles, amines (including pyridines, pyrrols, pyrrolydones and pyrrolidines), amides, imines, di-imines, imides, cyanates, isocyanates, nitrites and nitroso compounds, aldehydes, ketones, carboxylic esters, and their corresponding thio-compounds (thiols, sulphides, disulfides).

Owner:TOTAL RES & TECH FELUY

Environmentally friendly adhesives for bonding vulcanized rubber

InactiveUS6841600B2Improve adhesionGood layover characteristicNon-macromolecular adhesive additivesOrganic dyesElastomerZinc phosphate

Adhesive compositions effective for bonding runner to metal and containing no more than about 1000 ppm of lead especially adapted to bond vulcanized elastomers to rigid substrates, like metal are disclosed. The adhesives are useful in combination with primer coats, and as one-coat adhesives and provide durable, rubber tearing primary adhesive bonds after exposure to harsh conditions. The adhesives exhibit excellent bond versatility, sweep resistance, and in-can storage stability. In one embodiment, the adhesive compositions of the present invention consist essentially of less than 1000 ppm of lead, at least one diluent as water or organic solvent, a halogen-containing film former, optionally a nitroso compound, brominated dichlorobutadiene, and / or adhesion promoter, and an acid scavenger comprising zinc phosphate.

Owner:LORD CORP

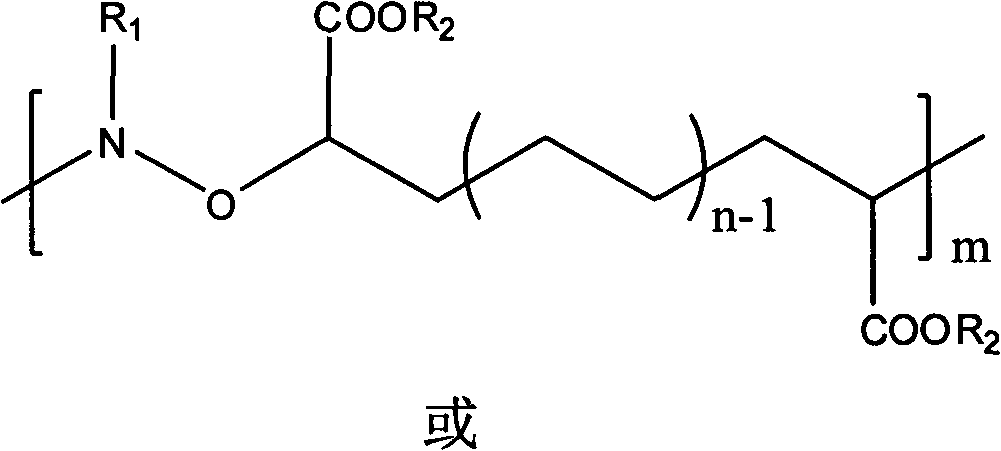

Process for inhibition of polymerization of (meth)acrylate ester

ActiveUS7241915B2Organic compound preparationPreparation from ortho-estersMeth-2,2,6,6-Tetramethylpiperidine

The present invention provides a process for inhibition of polymerization of a (meth)acrylate ester, which has an extremely higher effect of inhibition of polymerization than in cases where conventional polymerization inhibitors are used. In the process for inhibition of polymerization of a (meth)acrylate ester; an N-oxyl compound and at least one member selected from the group consisting of manganese salt compounds, copper salt compounds, 2,2,6,6-tetramethylpiperidine compounds, and nitroso compounds are used together as polymerization inhibitors, and further an acid is used.

Owner:NIPPON SHOKUBAI CO LTD

Method for preparing copolymer with multielement alternating structure

The invention discloses a method for preparing a copolymer with a multielement alternating structure. The method comprises the following steps of: in the presence of a solvent, adding 1mol of nitroso compound, 0.5 to 5mol of dibromo compound, 1 to 10mol of metallic copper or copper salt and 1 to 10mol of polyamine to a reactor and stirring, and reacting for 0.1 to 24 hours at the temperature of 10 to 100 DEG C after deoxidized to obtain the copolymer with the multielement alternating structure. The invention has simple synthetic method and mild reaction condition and can utilize the dibromo compound with different structures to be reacted with the nitroso compound to obtain the copolymer with the multielement alternating structure. The invention overcomes defects of the traditional methods, synthesizes the high molecular weight (Mn>50,000g / mol) copolymer with the multielement alternating structure, and expands the new method for synthetizing high molecules.

Owner:ZHEJIANG UNIV

Preparation method of emulsion polymerized rubber without nitroso compound

A process for preparing the emulsion polymerization rubber (butadiene styrene rubber) not containing nitroso compound features that the components D, E and S are used as the reaction terminating agents to replace original SDD, DEHA and sodium nitrite in a defined manner. The said D is the monoalkyl or monoaryl bithioaminoformate. The said E is the hydroxyamine hydrochloride (or sulfate). The saidS is sodium sulfite or hydrated sodium sulfide.

Owner:CHINA PETROLEUM & CHEM CORP

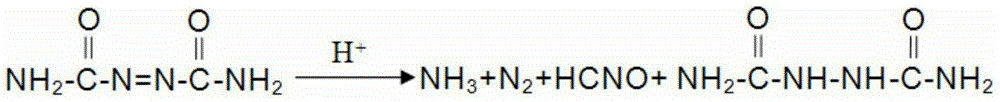

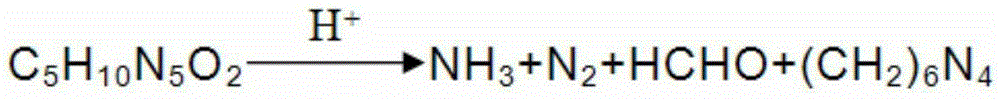

Slow-release plastic expanding agent for cement-based binding material and preparation method of slow-release plastic expanding agent

The invention provides a slow-release plastic expanding agent for a cement-based binding material and a preparation method of the slow-release plastic expanding agent and particularly relates to a plastic expanding agent capable of continuously generating certain expansion to compensate for early shrinkage of the cement-based binding material before the stage that a cement-based binding material mixture loses plasticity. The slow-release plastic expanding agent for the cement-based binding material is prepared from, by weight, 30-50 parts of aliphatic azo compounds, 20-40 parts of N-nitro compounds, 5-20 parts of foaming promoter and 5-15 parts of foam stabilizer. When the slow-release plastic expanding agent, polycarboxylate water reducing agent, a naphthalene water reducing agent and an aliphatic water reducing agent are compounded for use, the viscosity of the cement-based binding material mixture is slightly increased, the workability of the mixture is improved, micro-expansion is generated, and early shrinkage of the cement-based binding material mixture can be offset to a certain degree.

Owner:武汉市恒星防水材料有限公司

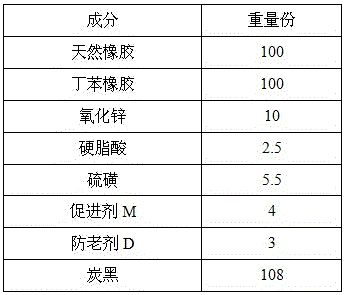

Natural rubber/butadiene styrene rubber metal HTV (Hot Vulcanization) adhesive

ActiveCN105670548ALow toxicityIncreased toxicityPolyureas/polyurethane adhesivesChloroprene adhesivesNitro compoundEpoxy

The invention discloses a natural rubber / butadiene styrene rubber metal HTV (Hot Vulcanization) adhesive, and relates to a rubber vulcanization adhesive. The natural rubber / butadiene styrene rubber metal HTV adhesive is prepared from the following components in percentage by weight: 1 to 2 percent of halogenated rubber, 18 to 22 percent of isocyanate, 9 to 12 percent of epoxy resin and the balance of solvent; or the natural rubber / butadiene styrene rubber metal HTV adhesive is prepared from the following components in parts by weight: 0.5 to 2.5 percent of halogenated rubber, 15 to 25 percent of isocynate, 7 to 25 percent of epoxy resin and the balance of solvent. The natural rubber / butadiene styrene rubber metal HTV adhesive disclosed by the invention contains no nitro compounds or lead salt, is used for adhering natural rubber or butadiene styrene rubber to metal through an HTV mode, and has good adhesion effect and low toxicity.

Owner:沈阳盖德橡胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com